This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

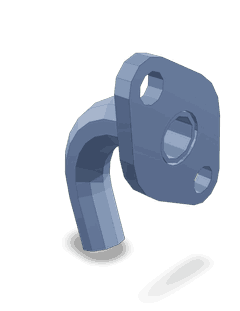

The Lubricating Oil Bypass Tube 216356 is a component designed by Cummins for use in heavy-duty truck engines. Its purpose is to facilitate the efficient operation of the engine’s lubrication system by managing oil flow and pressure. This component ensures that the engine receives consistent lubrication under varying operating conditions, contributing to the overall performance and longevity of the engine 1.

Function and Operation

The Lubricating Oil Bypass Tube operates within the engine’s lubrication system by providing an alternative pathway for oil to flow when the primary oil filter becomes restricted. This mechanism helps maintain consistent oil pressure and flow, ensuring that engine components remain adequately lubricated. The tube allows excess oil to bypass the filter and return to the oil sump, preventing pressure build-up that could otherwise lead to filter bypass or engine damage 2.

Key Features

This Cummins part is constructed from high-quality materials to ensure durability and reliability. Its design includes precision-machined components to ensure a proper fit and function within the engine system. The tube is engineered to withstand high pressures and temperatures, common in heavy-duty truck applications. Additionally, the component is designed for easy installation and maintenance, featuring straightforward connections and accessible design elements 3.

Benefits

The Lubricating Oil Bypass Tube offers several advantages. It enhances engine protection by ensuring consistent lubrication, even under demanding conditions. This consistent lubrication contributes to improved engine efficiency and reduced wear on critical components. Furthermore, the tube helps prolong the lifespan of engine parts by maintaining optimal oil flow and pressure, thereby supporting the engine’s overall performance and reliability 4.

Installation and Maintenance

Proper installation of the Lubricating Oil Bypass Tube involves ensuring that all connections are secure and that the tube is correctly positioned within the engine’s lubrication system. It is important to follow manufacturer guidelines to avoid potential issues. Regular maintenance includes checking for signs of wear or damage, ensuring that connections remain tight, and verifying that the tube is functioning as intended. Periodic inspection and cleaning can help maintain optimal performance and longevity of the component 5.

Troubleshooting Common Issues

Typical problems associated with the Lubricating Oil Bypass Tube may include leaks or blockages. Leaks can often be traced to loose connections or damaged seals, which can be addressed by tightening connections or replacing seals as necessary. Blockages may require disassembling the tube to clear any obstructions or replacing the tube if damage is detected. Regular maintenance and inspections can help identify and resolve these issues before they lead to more significant problems 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s product range includes a variety of engine and component solutions designed to meet the demanding requirements of commercial and industrial applications 7.

Compatibility

The Lubricating Oil Bypass Tube, identified by part number 216356, is compatible with various Cummins engine models, including the V903, VTA903, CM2250, and V105 engines. This part is designed to facilitate the controlled bypass of lubricating oil, ensuring that the engine operates smoothly and efficiently across different engine types 8.

Role in Engine Systems

In the orchestration of engine components, the Lubricating Oil Bypass Tube (part 216356) assumes a significant role in maintaining the integrity and efficiency of the lubrication system. This component is strategically positioned to interact with several key elements within the engine.

The bypass tube is integral to the operation of the lubricating oil pump. It provides an alternative pathway for oil to flow when the primary route is obstructed or when the pressure within the system exceeds predefined limits. This ensures that the lubricating pump bypass mechanism can activate, preventing damage to the pump and maintaining consistent oil flow to critical engine parts.

Within the cylinder block, the bypass tube facilitates the distribution of oil to various bearing surfaces and moving parts, ensuring that they remain adequately lubricated under all operating conditions. This is particularly important during high-stress scenarios where the demand for lubrication is at its peak.

The pan of the engine, which collects and stores oil, is also influenced by the bypass tube’s function. By regulating the flow of oil back into the pan, the bypass tube helps maintain the oil level and pressure, which is essential for the overall health of the lubrication system.

Furthermore, the bypass tube interacts with the pump itself, ensuring that the oil circulating through the engine is clean and free from contaminants. This is achieved by allowing oil to bypass filters when they become clogged, thus preserving the pump’s efficiency and longevity 9.

Conclusion

The Lubricating Oil Bypass Tube 216356 plays a crucial role in the efficient operation of heavy-duty truck engines by managing oil flow and pressure within the lubrication system. Its design and construction ensure durability, reliability, and ease of maintenance. By providing consistent lubrication under varying conditions, this component contributes to improved engine efficiency, reduced wear on critical components, and prolonged engine lifespan. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F4.5 CM2620 F152C. Bulletin Number 6324124.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F4.5 CM2620 F152C. Bulletin Number 6324124.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F4.5 CM2620 F152C. Bulletin Number 6324124.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F4.5 CM2620 F152C. Bulletin Number 6324124.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F4.5 CM2620 F152C. Bulletin Number 6324124.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.