This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Lubricating Oil Pump, part number 2874011, is a critical component in the operation of heavy-duty trucks. Manufactured by Cummins, a renowned name in the automotive industry, this part ensures that engines receive adequate lubrication, which is essential for performance and longevity.

Basic Concepts of Lubricating Oil Pumps

A lubricating oil pump circulates oil throughout an engine to reduce friction between moving parts, remove heat, and carry away contaminants 1. Its primary functions include maintaining oil pressure and ensuring consistent oil flow to critical engine components. Proper lubrication is fundamental to the health of an engine, minimizing wear and tear, enhancing efficiency, and contributing to the overall reliability of the vehicle 2.

Purpose of the Cummins Lubricating Oil Pump

The Cummins Lubricating Oil Pump, part 2874011, is designed to facilitate the circulation of oil within a truck’s engine, ensuring that all moving parts are adequately lubricated. It maintains the necessary oil pressure to support the engine’s operation under various conditions, thereby playing a key role in the engine’s performance and durability.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials, which contribute to its performance and durability. Its construction allows for efficient oil circulation and pressure maintenance, even under demanding conditions. Unique attributes of this pump may include advanced sealing technologies and precision-engineered components that enhance its reliability and efficiency.

Benefits

Utilizing the Cummins Lubricating Oil Pump offers several advantages, such as improved engine performance due to optimal lubrication, increased engine longevity through reduced wear on components, and enhanced reliability under various operating conditions. Its efficient operation contributes to the overall efficiency of the truck, ensuring smooth and dependable performance.

Installation and Integration

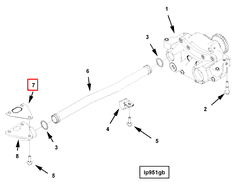

Proper installation of the Cummins Lubricating Oil Pump within a truck’s engine system is crucial for its optimal performance. This process involves ensuring the pump is correctly positioned and securely fastened, with all connections properly sealed to prevent leaks. Consideration should be given to the pump’s compatibility with the engine system to ensure seamless integration.

Troubleshooting and Maintenance

To ensure the longevity and efficiency of the Cummins Lubricating Oil Pump, regular maintenance and troubleshooting are recommended. Common maintenance practices include checking for signs of wear or failure, such as unusual noises or a drop in oil pressure, and performing routine inspections and replacements as necessary. Addressing issues promptly can prevent more significant problems and extend the pump’s lifespan.

Performance Under Various Conditions

The Cummins Lubricating Oil Pump is designed to perform effectively under a range of operating conditions, including extreme temperatures and heavy loads. Its robust construction and advanced features allow it to adapt to these conditions, maintaining efficient oil circulation and pressure. Understanding its performance capabilities under different scenarios can help in optimizing its use and ensuring the engine’s health.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. Its product range includes components for heavy-duty trucks, demonstrating its expertise and leadership in the field.

Compatibility of Cummins Lubricating Oil Pump Part 2874011

The Cummins lubricating oil pump part number 2874011 is designed to fit a range of Cummins engines, ensuring efficient oil circulation and engine protection. This part is compatible with the following engines:

ISX12/ISX11.9 CM2250

The ISX12 and ISX11.9 CM2250 engines are part of Cummins’ heavy-duty lineup, known for their robust performance and reliability. The lubricating oil pump part 2874011 is engineered to meet the specific requirements of these engines, providing optimal oil flow and pressure.

ISZ13 CM2150 Z105

The ISZ13 CM2150 Z105 engine is another member of Cummins’ lineup, designed for medium-duty applications. This engine benefits from the precise engineering of the lubricating oil pump part 2874011, ensuring that oil is distributed evenly throughout the engine, enhancing longevity and performance.

QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102

Both the QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102 engines are part of Cummins’ medium-duty range, tailored for various commercial applications. The lubricating oil pump part 2874011 is specifically designed to fit these engines, ensuring that they receive the necessary lubrication to operate smoothly and efficiently.

Z13 Z108G

The Z13 Z108G engine is another variant in Cummins’ medium-duty engine series. The lubricating oil pump part 2874011 is compatible with this engine, providing the essential oil flow required to maintain engine health and performance.

By ensuring that the lubricating oil pump part 2874011 is correctly installed, users can maintain the integrity and efficiency of their Cummins engines, preventing potential damage and extending the lifespan of their machinery.

Role of Part 2874011 Lubricating Oil Pump in Engine Systems

The Cummins Lubricating Oil Pump, part 2874011, is integral to maintaining the efficiency and longevity of engine systems. It operates by drawing oil from the sump and delivering it under pressure to various engine components. This ensures that moving parts, such as the crankshaft, camshaft, pistons, and bearings, receive a continuous supply of lubricant.

As the pump circulates oil, it passes through the oil filter, which removes contaminants and ensures that clean oil is distributed throughout the engine. The pressurized oil then flows through the main oil gallery, branching out to smaller galleries and passages that feed oil to critical components.

For the crankshaft, oil is delivered through drilled passages within the crankshaft itself, ensuring that the main and rod bearings are adequately lubricated. This reduces friction and wear, allowing for smooth operation.

The camshaft also benefits from the oil supplied by the pump. Lubricating oil reaches the cam lobes and followers, minimizing wear from the high-pressure contacts during valve operation.

Pistons and connecting rods receive oil via jet nozzles or drilled passages, which spray oil onto the cylinder walls. This not only lubricates the piston rings but also cools the cylinder walls, enhancing engine performance and durability.

Conclusion

In summary, the Cummins Lubricating Oil Pump, part 2874011, plays a significant role in the efficient operation of engine systems by ensuring that all moving parts are properly lubricated, thereby reducing friction, wear, and heat generation. Proper installation, maintenance, and understanding of its performance under various conditions are essential for maximizing the benefits of this critical component.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.