This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

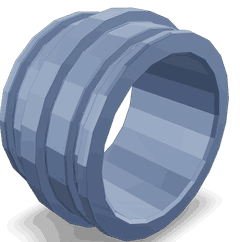

The Lubricating Oil Transfer Tube (Part #2887542) by Cummins is a component designed to facilitate the efficient transfer of lubricating oil within the engine system of commercial trucks. Its role is significant in maintaining the smooth operation and longevity of the engine by ensuring that oil is properly distributed to critical components 1.

Basic Concepts of Lubricating Oil Transfer Tubes

A Lubricating Oil Transfer Tube is a conduit within the lubrication system that directs oil from the oil pan to various engine components. This tube plays a role in the lubrication system by ensuring that oil reaches bearings, pistons, and other moving parts, thereby reducing friction and wear 2. Proper lubrication is vital for the overall performance and durability of the engine.

Purpose of the Lubricating Oil Transfer Tube

The Lubricating Oil Transfer Tube serves to transfer oil to various engine components, ensuring they receive the necessary lubrication for optimal operation. By facilitating the flow of oil, it helps maintain the engine’s efficiency and reduces the risk of wear and damage to critical parts.

Key Features

The Lubricating Oil Transfer Tube is designed with several key features to enhance its performance. It is constructed from durable materials to withstand the high temperatures and pressures within the engine. The tube’s design ensures a consistent flow of oil, and it may include features such as reinforced sections to prevent leaks and ensure longevity.

Benefits

Using the Lubricating Oil Transfer Tube offers several benefits. It improves lubrication efficiency by ensuring a steady supply of oil to engine components. This consistent lubrication reduces wear on parts, contributing to the engine’s overall performance and longevity. Additionally, proper lubrication helps maintain optimal engine temperature and reduces the risk of overheating 3.

Installation Process

Installing the Lubricating Oil Transfer Tube requires careful attention to detail. The process involves disconnecting the old tube, if present, and connecting the new tube to the oil pan and engine components. Tools such as wrenches and sealant may be necessary. Safety precautions, including ensuring the engine is cool and disconnected from power sources, should be observed during installation.

Maintenance Tips

To ensure the Lubricating Oil Transfer Tube operates efficiently, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage, cleaning it to remove any debris, and replacing it according to the manufacturer’s guidelines. Proper maintenance helps prevent leaks and ensures the tube continues to function effectively.

Troubleshooting Common Issues

Common issues with the Lubricating Oil Transfer Tube may include leaks, blockages, or damage to the tube. Troubleshooting steps involve inspecting the tube for visible signs of damage, checking connections for tightness, and ensuring there are no obstructions in the oil flow. Addressing these issues promptly can prevent more significant problems and maintain engine performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its innovative solutions and commitment to quality. The company offers a wide range of products designed to meet the needs of various industries, ensuring reliable and efficient performance.

Cummins Engine Compatibility with Lubricating Oil Transfer Tube Part 2887542

The Cummins-manufactured Lubricating Oil Transfer Tube part number 2887542 is designed to be compatible with a range of Cummins engines, including the QSK95 CM2350 K111 and QSK95 CM2350 K113 models. This part plays a role in the engine’s lubrication system, ensuring that oil is efficiently transferred from the oil sump to the engine’s moving parts, thereby maintaining optimal lubrication and reducing wear and tear.

Engine Compatibility

- QSK95 CM2350 K111 and QSK95 CM2350 K113

These engines are part of Cummins’ QSK95 series, which is known for its reliability and efficiency in various industrial and marine applications. The part 2887542 is specifically engineered to fit these models, ensuring seamless integration and performance. The compatibility of this lubricating oil transfer tube with these engines underscores Cummins’ commitment to providing high-quality, durable components that enhance engine longevity and efficiency.

Importance of the Lubricating Oil Transfer Tube

The lubricating oil transfer tube is a vital component in the engine’s lubrication system. It ensures that oil is properly circulated throughout the engine, providing essential lubrication to critical parts and preventing overheating and mechanical failure. The design and material of part 2887542 are optimized to withstand the high pressures and temperatures found in modern diesel engines, ensuring reliable performance over extended periods.

Installation and Maintenance

Proper installation of the lubricating oil transfer tube is important to maintaining engine health. Technicians should follow Cummins’ recommended procedures for installing this part to ensure it functions correctly. Regular maintenance checks should also be performed to inspect the tube for any signs of wear, leaks, or blockages, which could compromise the engine’s lubrication system.

By ensuring that the lubricating oil transfer tube part 2887542 is correctly installed and maintained, engine operators can benefit from improved engine performance, reduced downtime, and extended service life.

Role of Part 2887542 Lubricating Oil Transfer Tube in Engine Systems

The Part 2887542 Lubricating Oil Transfer Tube is integral to the efficient operation of engine systems by facilitating the seamless transfer of lubricating oil between various components. This component ensures that the lubricating oil is consistently circulated, maintaining optimal lubrication and cooling of engine parts.

Interaction with the Lubricating Oil Filter

The transfer tube works in conjunction with the lubricating oil filter to ensure that clean oil is distributed throughout the engine. As the oil passes through the filter, contaminants are removed, and the transfer tube then conveys the purified oil to other parts of the engine, enhancing performance and longevity.

Coordination with the Lubricating Oil Filter Head

When integrated with the lubricating oil filter head, the transfer tube plays a key role in maintaining a steady flow of oil. The filter head often includes bypass valves and pressure relief mechanisms, and the transfer tube ensures that oil reaches these components without interruption, supporting the filter head’s function in regulating oil pressure and flow.

Integration within the Lubricating Oil Filter Kit

In a lubricating oil filter kit, the transfer tube is a vital link that connects the filter assembly to the engine’s lubrication system. This kit typically includes the filter, gaskets, and other necessary components. The transfer tube ensures that the filtered oil is efficiently transferred from the filter to the engine, supporting the kit’s overall purpose of maintaining clean and effective lubrication.

Overall System Functionality

By ensuring a consistent and clean supply of lubricating oil, the transfer tube supports the engine’s lubrication system in reducing friction, dissipating heat, and protecting against wear. Its role is important in maintaining the health and efficiency of the engine, working harmoniously with filters and other components to deliver reliable performance.

Conclusion

The Lubricating Oil Transfer Tube (Part #2887542) by Cummins is a critical component in the engine’s lubrication system, ensuring efficient oil transfer and maintaining optimal engine performance. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to leveraging the full benefits of this part. Cummins’ commitment to quality and compatibility ensures that this part integrates seamlessly with their engines, contributing to enhanced engine longevity and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.