2892025

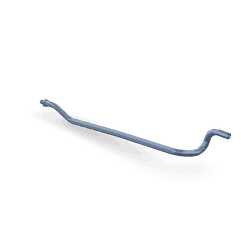

Lubricating Oil Drain Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Lubricating Oil Drain Tube, Part #2892025 by Cummins, is a component designed for the maintenance of heavy-duty trucks. Cummins, a well-established manufacturer in the automotive industry, produces this part to ensure efficient oil management within the engine system. The drain tube is integral to the maintenance routine of heavy-duty vehicles, facilitating the removal of used oil, which is a key aspect of engine care 1.

Function and Operation

The Lubricating Oil Drain Tube operates by providing a pathway for used oil to exit the engine during an oil change. This process is vital for maintaining engine health, as it allows for the replacement of old, contaminated oil with fresh lubricant. Regular oil changes are important for reducing engine wear, improving fuel efficiency, and ensuring the engine operates within optimal temperature ranges 2.

Key Features

The design of the Lubricating Oil Drain Tube incorporates materials and construction techniques that enhance its performance and durability. It is engineered to withstand the high temperatures and pressures associated with engine operation. The tube’s material is chosen for its resistance to corrosion and its ability to maintain structural integrity over time, ensuring a reliable seal and efficient oil drainage 3.

Benefits of Using the Lubricating Oil Drain Tube

Utilizing the Cummins Lubricating Oil Drain Tube offers several advantages. It contributes to improved engine longevity by ensuring that oil changes are conducted smoothly and efficiently. The design of the tube also simplifies maintenance procedures, reducing the time required for oil changes. Furthermore, its robust construction ensures reliability, even in the demanding conditions often encountered by heavy-duty trucks.

Installation and Compatibility

Proper installation of the Lubricating Oil Drain Tube is important for its effective operation. Installation procedures may vary slightly depending on the specific engine model, but generally involve securing the tube in place and ensuring a tight seal to prevent leaks. Compatibility with various Cummins engine models is a key consideration, and the tube is designed to fit seamlessly within the engine system, adhering to Cummins’ standards for quality and performance.

Maintenance and Troubleshooting

To ensure the Lubricating Oil Drain Tube operates at peak efficiency, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage, such as cracks or leaks, and addressing any issues promptly to prevent oil loss or contamination. Troubleshooting common problems, such as blockages, involves checking for debris within the tube and clearing any obstructions to restore proper oil flow.

Safety Considerations

When working with the Lubricating Oil Drain Tube, it is important to observe safety practices to protect against burns from hot oil and to ensure the proper disposal of used lubricants. Handling the tube and performing maintenance should be done with care, using appropriate personal protective equipment and following established safety protocols to minimize the risk of injury or environmental harm.

Environmental Impact

The use and disposal of lubricating oil have environmental considerations. The design of the Lubricating Oil Drain Tube contributes to minimizing environmental harm by facilitating the efficient drainage and collection of used oil. Proper disposal of used oil, in accordance with local regulations, is important to prevent contamination of soil and water sources. Cummins is committed to producing components that not only perform well but also consider the environmental impact of their use and disposal.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for a variety of applications. The company’s product range includes engines for on-highway, off-highway, and stationary applications, demonstrating its versatility and expertise in the automotive and heavy-duty truck sectors.

Cummins Engine Compatibility with Lubricating Oil Drain Tube Part 2892025

The Cummins part number 2892025, a Lubricating Oil Drain Tube, is designed to fit seamlessly into several of Cummins’ engine models. This part is crucial for the maintenance and operation of these engines, ensuring that oil is properly drained and the engine remains lubricated.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

The ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines are part of Cummins’ heavy-duty lineup, known for their robust performance and reliability. The lubricating oil drain tube part 2892025 is specifically engineered to fit these engines, facilitating efficient oil drainage and contributing to the overall maintenance of the engine’s lubrication system.

QSX11.9 CM2250 ECF

The QSX11.9 CM2250 ECF engine, another member of Cummins’ extensive engine family, is designed for versatility and efficiency. The lubricating oil drain tube part 2892025 is compatible with this engine, ensuring that it operates smoothly by allowing for proper oil drainage and maintaining the necessary lubrication levels.

These engines, while differing in some specifications, share a common requirement for high-quality maintenance parts like the lubricating oil drain tube part 2892025. This part’s compatibility across these models underscores its importance in maintaining the health and performance of Cummins engines.

Role of Part 2892025 Lubricating Oil Drain Tube in Engine Systems

In the context of engine systems, the 2892025 Lubricating Oil Drain Tube is an essential component that facilitates the efficient management of lubricating oil. This tube is integral to the overall arrangement of the engine’s lubrication system, ensuring that oil is properly circulated and drained as needed.

Integration with the Crankcase Breather System

The 2892025 tube works in conjunction with the crankcase breather system to maintain optimal engine performance. The crankcase breather allows gases to escape from the crankcase, which is vital for preventing the buildup of pressure that could lead to oil leaks or engine damage. The drain tube ensures that any oil that may be carried over with these gases is efficiently returned to the sump, thus maintaining the oil level and ensuring continuous lubrication of engine components.

Enhancing Oil Management

By providing a dedicated pathway for oil drainage, the 2892025 tube enhances the overall oil management within the engine. This is particularly important in high-performance or high-stress engine environments where consistent lubrication is paramount. The tube’s design allows for seamless integration into the engine’s lubrication circuit, promoting reliable operation and extending the lifespan of engine components.

Supporting Engine Maintenance

From a maintenance perspective, the 2892025 Lubricating Oil Drain Tube simplifies the oil change process. By offering a clear and direct route for oil to exit the engine, it reduces the risk of spills and makes the procedure more straightforward for mechanics. This not only saves time but also enhances the safety and efficiency of routine maintenance tasks.

Conclusion

In summary, the 2892025 Lubricating Oil Drain Tube plays a significant role in the lubrication system by ensuring proper oil circulation, supporting the crankcase breather system, and facilitating easier maintenance procedures. Its design and compatibility with various Cummins engine models underscore its importance in maintaining the health and performance of heavy-duty engines.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.