This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2894739 Wear Sleeve is engineered to enhance the durability and efficiency of heavy-duty truck engines. It plays a crucial role in maintaining the operational integrity of the engine, especially under demanding conditions typical of heavy-duty applications.

Purpose and Function

This Cummins part is strategically positioned within the engine to protect critical components from wear and tear. It interacts closely with the piston and cylinder, providing a smooth surface that reduces friction and wear. This interaction is vital for the efficient operation of the engine, ensuring that the piston moves smoothly within the cylinder, which is fundamental for the engine’s performance and longevity 1.

Key Features

The design of the Wear Sleeve incorporates materials and engineering that enhance its performance and durability. It is crafted from high-quality materials that offer superior resistance to wear and corrosion. The sleeve’s precise engineering ensures a perfect fit within the engine, which is crucial for its effective function. Additionally, its design may include features that facilitate easy installation and removal, contributing to its overall utility 2.

Benefits

Incorporating the Wear Sleeve into a truck’s engine can lead to several advantages. It contributes to improved engine longevity by reducing wear on critical components. This reduction in wear can lead to lower maintenance costs over the engine’s lifespan. Furthermore, the sleeve enhances the overall performance of the engine by ensuring smooth operation and efficient power delivery 3.

Installation Process

Installing the Wear Sleeve requires careful attention to detail to ensure proper fit and function. The process involves preparing the engine compartment, removing the old sleeve if applicable, and inserting the new sleeve. Tools and additional components may be required to complete the installation, ensuring that the sleeve is securely in place and functions as intended 4.

Troubleshooting Common Issues

Wear sleeves, including the 2894739, may encounter issues such as wear beyond expected limits or improper fit. Identifying these problems early can prevent more significant engine damage. Diagnostic procedures may involve inspecting the sleeve for signs of wear or damage and ensuring it is correctly installed. Repair or replacement may be necessary if issues are detected 5.

Maintenance Tips

Regular maintenance of the Wear Sleeve is crucial for its longevity and optimal performance. This includes routine inspections for signs of wear or damage, ensuring it remains securely in place, and addressing any issues promptly. Adhering to manufacturer recommendations for maintenance intervals and procedures can help maintain the sleeve’s effectiveness and contribute to the engine’s overall reliability 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the automotive industry. Its product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of vehicles and equipment.

Compatibility

The Wear Sleeve part number 2894739 is designed to fit seamlessly with several Cummins engine models, ensuring optimal performance and longevity. This wear sleeve is a critical component in maintaining the integrity of the engine’s internal mechanisms.

G855 Engines

For the G855 engine series, the Wear Sleeve 2894739 is engineered to provide a precise fit, ensuring that it can effectively reduce friction and wear within the engine. This part is essential for maintaining the smooth operation of the engine’s moving parts, contributing to overall engine reliability and efficiency.

N14 G Engines

Similarly, in the N14 G engine series, the Wear Sleeve 2894739 plays a crucial role in protecting the engine’s internal components. Its design ensures that it can withstand the rigors of heavy-duty operations, providing a durable solution to wear and tear. This part is integral to the engine’s performance, helping to maintain its operational standards over extended periods.

Grouping of Engines

Both the G855 and N14 G engines benefit from the Wear Sleeve 2894739 due to its universal design that caters to the specific needs of these engine models. The compatibility of this wear sleeve with these engines highlights its versatility and effectiveness in various engine configurations.

Role in Engine Systems

The Wear Sleeve is an essential component in various engine systems, facilitating smooth operation and longevity of interconnected parts. Its application spans across several critical areas within the engine, ensuring efficient power transmission and reduced wear on moving components.

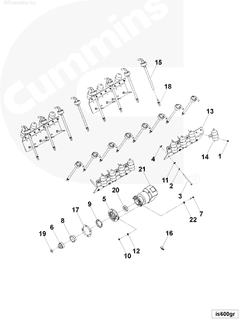

Fuel Governor System

In the Fuel Governor system, the Wear Sleeve provides a low-friction interface between the governor components and the drive mechanism. This reduces the wear on the governor’s moving parts, ensuring precise fuel control and consistent engine performance over time.

Drive Mechanisms

Across different drive mechanisms—whether it’s the main drive, accessory drive, or front gear train accessory drive—the Wear Sleeve is instrumental. It allows for smooth rotation and minimizes friction, which is vital for the efficient transfer of power from the engine to various accessories and components.

Governor and Magneto Drive

For the Governor and Magneto Drive, the Wear Sleeve ensures that the governor can modulate the engine’s speed accurately without undue wear. This is particularly important for maintaining ignition timing and fuel delivery in sync with engine demands, enhancing overall engine efficiency and reliability.

Mounting and Accessory Drives

In Mounting Accessory Drives and Governor & Magtroni systems, the Wear Sleeve facilitates the smooth operation of accessories connected to the engine. This includes components like alternators, water pumps, and other critical systems that rely on consistent and efficient power transmission from the engine.

Mechanical Governor Drive

Within the Mechanical Governor Drive, the Wear Sleeve is key to maintaining the integrity of the governor’s operation. It ensures that the mechanical linkages move freely, allowing the governor to respond accurately to changes in engine load and speed, thus maintaining optimal engine performance.

Engine Control System and Ignition

In the Engine Control System and Ignition setups, the Wear Sleeve contributes to the smooth operation of components that are critical for engine start-up, operation, and shutdown. By reducing friction and wear, it helps in maintaining the precision of ignition timing and fuel injection, which are paramount for engine efficiency and emissions control.

Pierce Governor Drive and Module Integration

For systems utilizing a Pierce Governor Drive or integrated within a Module, the Wear Sleeve ensures that the governor can operate within its designed parameters without excessive wear. This is essential for systems that require high precision in fuel and air mixture control, directly impacting engine performance and fuel economy.

Conclusion

The Cummins 2894739 Wear Sleeve is a versatile component that enhances the durability and efficiency of various engine systems by reducing friction and wear on moving parts. Its application across different engine components underscores its importance in maintaining engine performance and longevity.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Cummins Inc. Service Manual (5659622). Cummins Inc., 2023.

↩ -

Cummins Inc. Service Manual (5659622). Cummins Inc., 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.