This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3001722 Oil Cooler Support is a component designed to facilitate the mounting and operation of the oil cooler in commercial trucks. Its purpose is to ensure the oil cooler is securely positioned and functions effectively within the truck’s engine system. This support plays a role in the overall efficiency and reliability of the truck’s engine by contributing to the maintenance of optimal oil temperature 1.

Purpose and Function

The Oil Cooler Support serves a significant role in the truck’s oil cooling system. It provides a stable mounting platform for the oil cooler, which is responsible for dissipating excess heat from the engine oil. By maintaining the oil at an optimal temperature, the support helps to ensure the engine operates within its designed parameters, thereby contributing to engine performance and longevity 2.

Key Features

The Cummins 3001722 is constructed with durability and functionality in mind. It is made from high-quality materials that can withstand the rigors of commercial truck operation. The design includes robust mounting options to ensure a secure fit, and it may feature unique elements such as corrosion-resistant coatings or integrated brackets for additional support. These features contribute to the overall reliability and ease of installation of the component 3.

Benefits

Utilizing the Cummins 3001722 offers several advantages. It contributes to improved engine performance by ensuring the oil cooler is properly positioned and functions as intended. This can lead to enhanced engine longevity and reliability, as maintaining optimal oil temperature is crucial for engine health. Additionally, the secure mounting provided by the support can reduce the risk of oil cooler damage due to vibrations or impacts 4.

Installation Process

Installing the Oil Cooler Support involves several steps to ensure it is properly secured and functions correctly. The process typically requires standard tools such as wrenches and possibly a torque wrench to ensure bolts are tightened to the manufacturer’s specifications. It is important to follow the manufacturer’s instructions carefully, ensuring all components are correctly aligned and secured before operating the vehicle .

Maintenance and Troubleshooting

Regular maintenance of the Oil Cooler Support is important to ensure its continued effectiveness. This may include checking for signs of wear or damage, ensuring all mounting bolts are tight, and inspecting the oil cooler for proper operation. Common issues may include loose mounting bolts or damage to the support itself, which can often be addressed by re-tightening bolts or replacing damaged components as necessary .

Compatibility and Usage

The Cummins 3001722 is designed for use with specific types of trucks and engines. It is important to consult the manufacturer’s guidelines to ensure compatibility with your vehicle. Proper usage guidelines should be followed to ensure the support functions as intended and contributes to the overall performance and reliability of the truck .

Safety Considerations

When installing or maintaining the Oil Cooler Support, it is important to follow safety practices to protect both the mechanic and the vehicle. This includes ensuring the engine is cool before beginning work, using the correct tools and procedures, and following all manufacturer’s safety guidelines. Proper safety practices help to ensure the task is completed effectively and without incident .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, known for its commitment to quality, innovation, and customer satisfaction. The company’s products, including the 3001722, are designed with these principles in mind, offering reliable performance and durability for commercial applications .

Compatibility of Cummins 3001722 Oil Cooler Support

The Cummins Oil Cooler Support part number 3001722 is designed to fit seamlessly with a range of engine models, ensuring optimal performance and longevity. This support is integral to the engine’s cooling system, providing the necessary stability and alignment for the oil cooler.

NH/NT 855 Engines

For the NH/NT 855 engines, the Oil Cooler Support 3001722 plays a role in maintaining the integrity of the oil cooling system. This part is engineered to fit precisely within the engine’s architecture, ensuring that the oil cooler is securely positioned. This support helps in preventing any misalignment or movement that could potentially lead to system inefficiencies or damage.

The NH/NT 855 engines, known for their robust performance, benefit significantly from the use of this part. The support ensures that the oil cooler operates under optimal conditions, contributing to the overall reliability and efficiency of the engine.

By integrating the Oil Cooler Support 3001722 into the NH/NT 855 engines, users can expect enhanced cooling performance, which is vital for maintaining engine health and extending service life.

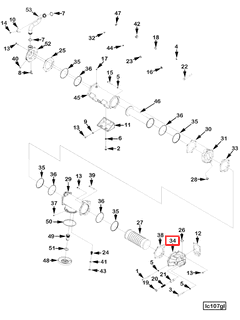

Role of Part 3001722 Oil Cooler Support in Engine Systems

The Part 3001722 Oil Cooler Support is an integral component in various engine systems, ensuring the efficient operation of oil cooling mechanisms. This support is designed to facilitate the integration of oil coolers within complex engine setups, enhancing the overall performance and longevity of the engine.

In systems involving the Engine Oil Cooler, the Oil Cooler Support provides a stable mounting platform, allowing for optimal positioning of the cooler. This ensures that the engine oil is effectively cooled, maintaining its viscosity and reducing the risk of overheating.

For the Torque Converter Oil Cooler, the support plays a similar role, securing the cooler in place to ensure that the torque converter fluid is adequately cooled. This is particularly important in automatic transmission systems, where the torque converter operates under high stress and heat.

In combined systems such as the Cooler LO & TC (Lubricating Oil and Torque Converter Cooler), the Oil Cooler Support is essential for maintaining the structural integrity of both coolers. It ensures that both the lubricating oil and the torque converter fluid are efficiently cooled, contributing to the smooth operation of the transmission and engine.

The Lubricating Oil and Turbocharger Cooler Assembly also benefits from the Oil Cooler Support. By providing a robust mounting solution, it helps in keeping the turbocharger and lubricating oil at optimal temperatures, which is vital for the turbocharger’s performance and durability.

In scenarios where a Lubricating Oil Cooler and T C Cooler are used together, the support ensures that both cooling systems are securely mounted and operate efficiently. This is crucial for engines that require precise temperature control of both lubricating oil and torque converter fluid.

Overall, the Part 3001722 Oil Cooler Support is a key component in maintaining the efficiency and reliability of various engine cooling systems, ensuring that all fluids remain at optimal temperatures for peak performance.

Conclusion

The Cummins 3001722 Oil Cooler Support is a vital component for the efficient operation of oil cooling systems in commercial trucks. Its design and features contribute to the reliability and performance of the engine by ensuring the oil cooler is securely mounted and functions effectively. Regular maintenance and proper installation are crucial for maximizing the benefits of this part, ensuring the engine operates within its optimal parameters and extends its service life.

-

Sclar, D. (2008). Auto Repair for Dummies: 2nd Edition. For Dummies.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Cummins Inc. (n.d.). Owners Manual for C Command Analog Marine Panel Systems PS101. Bulletin Number 5411200.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.