This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

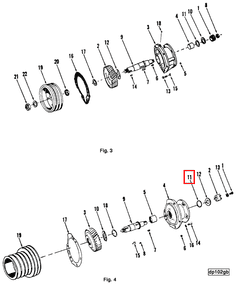

The Cummins 3006557 Wear Sleeve is a component designed for use in heavy-duty truck operations. It serves a specific function within the engine or transmission system, contributing to the overall efficiency and longevity of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Purpose and Function

This Cummins part plays a role in protecting and supporting moving parts within the engine or transmission system. It is specifically designed to reduce wear and tear on components that experience high levels of friction and stress. By providing a smooth surface for these parts to interact with, the wear sleeve helps maintain operational efficiency and extends the lifespan of the associated components 1.

Key Features

The design and material characteristics of 3006557 are tailored to enhance its performance and durability. Crafted from high-quality materials, it is engineered to withstand the demanding conditions within a heavy-duty truck’s engine or transmission. Its precise dimensions and smooth surface finish are critical attributes that contribute to its effectiveness in reducing friction and wear 2.

Benefits

This part offers several advantages. It contributes to the improved longevity of mating components by minimizing wear and reducing the need for frequent replacements. Additionally, it helps in reducing friction within the system, which can lead to enhanced overall efficiency. The wear sleeve also plays a part in maintaining consistent performance levels, ensuring that the truck operates smoothly over extended periods 3.

Installation Process

Proper installation of the Cummins 3006557 Wear Sleeve is vital for ensuring its effectiveness. The process involves several steps, including the preparation of the mating surfaces, the correct alignment of the sleeve, and the use of appropriate tools to secure it in place. Detailed instructions should be followed to avoid common installation pitfalls that could compromise the sleeve’s performance 4.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 3006557 Wear Sleeve. This includes periodic inspections for signs of wear or damage, cleaning the sleeve and its surrounding components, and addressing any issues promptly. Troubleshooting tips may involve checking for proper alignment, ensuring there is no excessive friction, and verifying that the sleeve is securely in place.

Common Issues and Solutions

Typical problems associated with wear sleeves can include misalignment, excessive wear, or damage due to contamination. Solutions to these issues may involve realigning the sleeve, replacing it if wear exceeds acceptable limits, or cleaning the system to remove contaminants. Addressing these problems promptly can help maintain the efficiency and reliability of the truck’s engine or transmission system.

Manufacturer Information

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industries. Known for its commitment to quality and innovation, Cummins has a history of producing reliable and high-performance components. The company’s dedication to advancing technology and meeting the needs of its customers is evident in the design and functionality of the Cummins 3006557 Wear Sleeve.

Conclusion

Understanding the role, benefits, and maintenance requirements of the Cummins 3006557 Wear Sleeve is essential for ensuring the optimal performance and longevity of heavy-duty trucks. By adhering to proper installation procedures, regular maintenance, and prompt troubleshooting of common issues, truck operators can maximize the efficiency and reliability of their vehicles.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.