This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

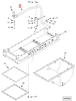

The Lubricating Oil Suction Tube, identified by part number 3009724, is a component manufactured by Cummins, a reputable name in the automotive industry. This tube is integral to the lubrication system of heavy-duty trucks, ensuring that the engine operates smoothly and efficiently. Cummins designs this part to meet the demanding requirements of commercial vehicle engines.

Function and Operation

The Lubricating Oil Suction Tube operates within the engine’s lubrication system by facilitating the circulation of oil from the oil pan to the engine’s various moving parts. It plays a role in maintaining optimal lubrication levels, which is vital for reducing friction and wear between components. The tube is designed to efficiently draw oil, ensuring a consistent supply that supports the engine’s performance and longevity 1.

Purpose of the Lubricating Oil Suction Tube

The specific role of the Lubricating Oil Suction Tube in a truck’s operation is to contribute to engine performance and longevity by ensuring that all moving parts receive adequate lubrication. This part helps in maintaining the engine’s efficiency and reliability under various operating conditions, which is crucial for the overall performance of heavy-duty trucks 2.

Key Features

The Lubricating Oil Suction Tube is characterized by several primary features that enhance its functionality. These include a durable material composition designed to withstand the harsh conditions within an engine, a precise design that ensures efficient oil flow, and unique attributes such as reinforced sections to prevent leaks and blockages. These features collectively contribute to the tube’s effectiveness in the lubrication system 3.

Benefits

The advantages provided by the Lubricating Oil Suction Tube include improved engine efficiency through consistent oil circulation, reduced wear on engine components due to adequate lubrication, and enhanced overall performance of the lubrication system. These benefits contribute to the engine’s reliability and longevity, making the tube a valuable component in heavy-duty truck engines 4.

Installation and Compatibility

Proper installation of the Lubricating Oil Suction Tube is crucial for ensuring its effectiveness and the engine’s overall performance. Installation procedures should follow manufacturer guidelines to ensure compatibility with various truck models. Specific requirements or considerations may include alignment with other components and securing the tube to prevent movement or damage 5.

Maintenance and Troubleshooting

Routine maintenance practices for the Lubricating Oil Suction Tube involve regular inspections for signs of wear, leaks, or blockages. Troubleshooting common issues may include checking for proper alignment, ensuring secure connections, and addressing any leaks promptly to maintain the efficiency of the lubrication system. Regular maintenance helps in identifying potential problems early, ensuring the tube continues to function effectively 6.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a history of producing high-quality components for commercial vehicles. The company’s reputation is built on its commitment to innovation, quality, and reliability. Cummins’ components, including the Lubricating Oil Suction Tube, are designed to meet the rigorous demands of heavy-duty applications, ensuring optimal performance and durability in various operating conditions 7.

Conclusion

The Lubricating Oil Suction Tube (part number 3009724) by Cummins is a critical component in the lubrication system of heavy-duty trucks. Its design and functionality are tailored to ensure efficient oil circulation, reduce engine wear, and enhance overall engine performance and longevity. Proper installation, maintenance, and understanding of its role in the engine system are essential for maximizing the benefits of this Cummins part.

-

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Dixon, J. C. (1996). Tyres Suspension and Handling Second Edition. SAE International.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C, Bulletin Number 6310310.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C, Bulletin Number 6310310.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C, Bulletin Number 6310310.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.