This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

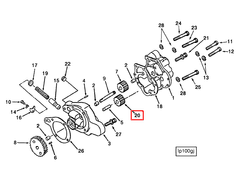

The Lubricating Oil Pump Gear (Part #3014966) by Cummins is a critical component designed to facilitate the operation of commercial trucks by ensuring the efficient circulation of lubricating oil within the engine. This gear is integral to the oil pump system, playing a significant role in maintaining optimal oil pressure and providing necessary lubrication to various engine components. Its proper function is vital for the overall performance and longevity of the engine.

Function and Operation

The Lubricating Oil Pump Gear operates within the oil pump system by meshing with another gear to create a pumping action. This action draws oil from the sump and delivers it under pressure to critical engine parts, such as bearings, pistons, and camshafts. By maintaining consistent oil pressure, the gear ensures that these components receive a continuous supply of lubricant, which reduces friction and wear, and helps in dissipating heat generated during engine operation 1.

Key Features

This Cummins part is constructed from high-quality materials, typically a durable alloy, to withstand the rigors of continuous operation within the engine environment. Its design specifications include precise gear tooth profiles and tolerances to ensure smooth engagement with its mating gear. Additionally, the gear may feature anti-wear coatings or treatments to enhance its performance and durability under high-stress conditions 2.

Benefits

The use of the Lubricating Oil Pump Gear contributes to improved engine efficiency by ensuring that all moving parts are adequately lubricated. This reduces friction and wear on engine components, leading to smoother operation and potentially extending the engine’s service life. Furthermore, proper lubrication facilitated by this gear can enhance the overall performance of the truck, allowing it to operate more reliably under various driving conditions 3.

Installation and Maintenance

For optimal performance and longevity, the Lubricating Oil Pump Gear should be installed according to manufacturer guidelines. This includes ensuring proper alignment and engagement with its mating gear, as well as verifying that all related components are clean and free of contaminants. Regular maintenance, such as inspection for wear, cleaning, and replacement when necessary, is recommended to prevent issues that could lead to engine damage or failure.

Troubleshooting

Common issues with the Lubricating Oil Pump Gear may include gear wear, misalignment, or contamination within the oil system. Troubleshooting steps may involve inspecting the gear for signs of wear or damage, checking the alignment of the gear within the pump, and ensuring the oil is clean and free of debris. Addressing these issues promptly can help minimize downtime and maintenance costs.

Manufacturer - Cummins

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its high-quality components and engines. With a long-standing reputation for innovation and reliability, Cummins is committed to producing parts that meet the demanding requirements of commercial vehicle applications. The company’s expertise and dedication to quality ensure that components like the Lubricating Oil Pump Gear are designed to deliver reliable performance and durability in various engine models and truck types.

Role of Part 3014966 Lubricating Oil Pump Gear in Engine Systems

The 3014966 Lubricating Oil Pump Gear is an integral component within the lubricating oil pump assembly, facilitating the efficient circulation of oil throughout the engine system. This gear works in conjunction with the lubricating oil pump to ensure a consistent flow of oil to vital engine components.

When the engine is operational, the lubricating oil pump draws oil from the oil pan through the scavenge pump body. The 3014966 gear, meshed with other gears within the pump, helps to pressurize the oil. This pressurized oil is then directed through the lubricating oil filter, where contaminants are removed, ensuring clean oil reaches the engine’s moving parts.

The clean, pressurized oil is essential for reducing friction between the base parts of the engine, such as bearings, pistons, and the crankshaft. This lubrication is vital for the longevity and performance of the engine.

In scenarios where an engine conversion kit is installed, the 3014966 gear ensures compatibility and efficiency within the new system configuration. Its role remains consistent: to maintain the necessary oil pressure and flow required for the engine’s operation, regardless of modifications or upgrades.

Overall, the 3014966 Lubricating Oil Pump Gear is a fundamental element in the oil circulation process, directly influencing the engine’s lubrication efficiency and, consequently, its overall performance and durability.

Conclusion

The Lubricating Oil Pump Gear (Part #3014966) by Cummins plays a crucial role in the efficient operation of commercial truck engines by ensuring the continuous circulation of lubricating oil. Its design and construction are tailored to withstand the demanding conditions within the engine, contributing to reduced friction, wear, and enhanced engine performance. Proper installation, maintenance, and timely troubleshooting are essential to maximize the benefits of this part, ultimately leading to improved engine longevity and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.