This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

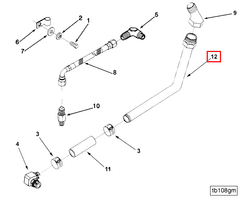

The Tur Oil Drain Tube, part number 3016456, manufactured by Cummins, is a component designed for the maintenance and operation of heavy-duty trucks. This part plays a role in the oil drainage system, which is integral to ensuring engine longevity and performance. Efficient oil drainage is vital for removing used oil from the engine, which helps maintain engine health and efficiency 1.

Function and Operation

The Tur Oil Drain Tube functions within the engine’s oil system by facilitating the removal of used oil. The process of oil drainage involves the tube allowing oil to flow out of the engine, which is crucial for regular maintenance routines. Efficient oil drainage is significant for maintaining engine health, as it ensures that contaminants and degraded oil are removed, reducing the risk of engine wear and damage 2.

Key Features

The Tur Oil Drain Tube part number 3016456 is characterized by several key features. It is constructed from materials that enhance durability and efficiency. The design includes elements that ensure a secure fit and reliable performance. Unique attributes of this tube may include specific threading or sealing mechanisms that differentiate it from other oil drain tubes, contributing to its effectiveness in heavy-duty applications 3.

Benefits of Using the Tur Oil Drain Tube

Utilizing the Tur Oil Drain Tube offers several advantages in terms of engine maintenance and performance. It contributes to extending engine life by ensuring efficient oil changes, which remove contaminants and degraded oil. This part also improves the efficiency of oil changes, reducing downtime during maintenance. Additionally, it helps minimize the risk of engine damage due to oil contamination, which can lead to increased engine wear and reduced performance 4.

Installation and Compatibility

Proper installation of the Tur Oil Drain Tube is important for its function and the overall health of the engine. Compatibility with various Cummins engine models ensures that the tube can be used across different applications. Specific installation requirements or considerations may include ensuring a proper seal and fit to prevent leaks and ensure efficient oil drainage 5.

Maintenance and Troubleshooting

Regular maintenance of the Tur Oil Drain Tube is recommended to ensure optimal performance. This includes inspecting the tube during routine oil changes for signs of wear or damage. Common issues that may arise with oil drain tubes include leaks or blockages, which can be addressed by cleaning or replacing the tube as necessary. Routine inspections help identify potential problems early, ensuring continued engine health 6.

Safety Considerations

When working with the Tur Oil Drain Tube, it is important to follow safety practices. Adhering to manufacturer guidelines for installation and maintenance helps avoid accidents or engine damage. Safety considerations include ensuring that the area is well-ventilated during oil changes and using appropriate personal protective equipment to protect against spills and contact with hot engine components 7.

Cummins Corporation Overview

Cummins Corporation has a history of innovation and quality in the automotive and heavy-duty truck industry. The company is known for its commitment to manufacturing high-quality engine components that meet the demands of heavy-duty applications. Cummins’ focus on quality and innovation ensures that their products, including the Tur Oil Drain Tube, are reliable and effective in maintaining engine performance and longevity 8.

Conclusion

In summary, the Tur Oil Drain Tube, part number 3016456, is a vital component for maintaining the health and efficiency of heavy-duty truck engines. Its role in the oil drainage system ensures that used oil is effectively removed, reducing the risk of engine wear and damage. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the benefits of this Cummins part.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

S. A. Miedema, Z. Lu, The Dynamic Behavior of a Diesel Engine, Published by Drir S. A. Miedema, 2010.

↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ -

Cummins Corporation, Service Manual (5411104), ISB6.7 G CM2180 B118.

↩ -

Cummins Corporation, Service Manual (5411104), ISB6.7 G CM2180 B118.

↩ -

Cummins Corporation, Service Manual (5411104), ISB6.7 G CM2180 B118.

↩ -

Cummins Corporation, Service Manual (5411104), ISB6.7 G CM2180 B118.

↩ -

Cummins Corporation, Service Manual (5411104), ISB6.7 G CM2180 B118.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.