This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3022316 Wear Sleeve is a component designed to enhance the operation of commercial trucks. A wear sleeve serves as a protective layer that reduces friction and wear on other components, thereby extending their lifespan and maintaining performance. In heavy-duty applications, such as those found in commercial trucking, wear sleeves play a significant role in ensuring that engines and other mechanical systems operate efficiently and reliably over extended periods 1.

Basic Concepts of Wear Sleeves

Wear sleeves are designed to shield critical components from the abrasive effects of friction and wear. They are typically made from durable materials that can withstand high levels of stress and exposure to various operating conditions. The fundamental principle behind wear sleeves is to create a barrier between moving parts, reducing direct contact and minimizing the wear that would otherwise occur. This protective function helps maintain the integrity and performance of the components they are designed to safeguard 3.

Purpose of the 3022316 Wear Sleeve

The Cummins 3022316 Wear Sleeve is specifically engineered to enhance the durability and performance of associated components within a truck’s engine system. By providing a protective layer, it reduces the wear on critical parts, ensuring they function smoothly and efficiently. This, in turn, contributes to the overall reliability and longevity of the engine, allowing for consistent performance even under demanding conditions 4.

Key Features

The Cummins 3022316 Wear Sleeve boasts several key features that set it apart. Its design is tailored to fit precisely within the engine system, ensuring optimal performance. The material composition is chosen for its durability and resistance to wear, making it suitable for heavy-duty applications. Additionally, the wear sleeve may include unique attributes such as enhanced surface treatments or specific dimensional tolerances that further improve its protective capabilities 2.

Benefits of Using the 3022316 Wear Sleeve

Incorporating the Cummins 3022316 Wear Sleeve into truck maintenance and operation offers several advantages. It contributes to increased longevity of engine components by reducing wear and tear. This, in turn, can lead to reduced maintenance costs over time, as components are less likely to fail prematurely. Furthermore, the wear sleeve helps improve overall engine performance by ensuring that components operate within their designed parameters, even under strenuous conditions 1.

Installation Process

Proper installation of the Cummins 3022316 Wear Sleeve is crucial for ensuring its effectiveness. The process involves several steps, including preparing the engine component for installation, aligning the wear sleeve correctly, and securing it in place. Tools and equipment required may include torque wrenches and alignment tools to ensure a precise fit. Following best practices during installation helps guarantee that the wear sleeve functions as intended, providing the maximum protective benefit 2.

Troubleshooting Common Issues

Common problems that may arise with the Cummins 3022316 Wear Sleeve include improper fit, damage during installation, or wear beyond its designed lifespan. Troubleshooting these issues involves inspecting the wear sleeve for signs of damage or misalignment, ensuring that it is correctly installed, and replacing it if necessary. Regular checks can help identify potential issues early, allowing for timely corrections and maintaining the performance of the engine system 1.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3022316 Wear Sleeve, regular maintenance practices are recommended. This includes periodic inspections to check for signs of wear or damage, cleaning the sleeve to remove any debris that may affect its function, and following manufacturer guidelines for replacement intervals. Adhering to these maintenance tips helps maintain the protective capabilities of the wear sleeve and contributes to the overall reliability of the engine system 2.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engine components, Cummins has established a strong reputation for excellence. The company’s product offerings span a wide range of applications, from heavy-duty trucks to industrial equipment, demonstrating its versatility and expertise in the automotive sector. Cummins’ dedication to manufacturing excellence ensures that its components, including the 3022316 Wear Sleeve, meet the highest standards of quality and performance 2.

Cummins Wear Sleeve 3022316 Compatibility with Engine Models

The Cummins Wear Sleeve part number 3022316 is designed to fit seamlessly within a range of engine models, ensuring optimal performance and longevity. This wear sleeve is specifically engineered to provide a protective barrier against wear and tear, enhancing the durability of the engine components it interfaces with.

K19 and K38 Engines

The Wear Sleeve 3022316 is compatible with both the K19 and K38 engines. These engines, while differing in some specifications, share common design elements that allow the wear sleeve to fit effectively. The sleeve’s precision engineering ensures it aligns perfectly with the internal components, reducing friction and wear, which is crucial for maintaining engine efficiency and lifespan 2.

K50 Engine

Similarly, the K50 engine also benefits from the use of the Wear Sleeve 3022316. This engine, known for its robust performance, requires high-quality wear protection to sustain its operational demands. The wear sleeve’s design fits snugly within the K50’s architecture, providing a reliable shield against the wear that occurs during high-stress operations 2.

Grouping for Efficiency

When considering the K19, K38, and K50 engines together, it is evident that the Wear Sleeve 3022316 is a versatile component. Its design accommodates the unique requirements of each engine model while offering a standardized solution for wear protection. This grouping highlights the efficiency and adaptability of the wear sleeve, making it a valuable part for maintaining these engines 2.

Role of Part 3022316 Wear Sleeve in Engine Systems

The 3022316 Wear Sleeve is an integral component in various engine systems, designed to enhance durability and performance. Its application spans across several key components, ensuring smooth operation and longevity.

Belt Guard

In the belt guard system, the 3022316 Wear Sleeve provides a protective layer that reduces friction between moving parts. This minimizes wear and tear on the belt, ensuring consistent performance and extending the lifespan of the belt guard 3.

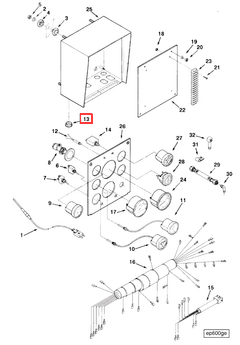

Instrument Panel

When integrated into the instrument panel, the Wear Sleeve facilitates the smooth movement of internal components. This is particularly important for gauges and switches, where precise movement is essential for accurate readings and reliable operation 4.

Instrument Panel Mounting

For the instrument panel mounting, the 3022316 Wear Sleeve ensures that the mounting points remain free from excessive wear. This stability is vital for maintaining the alignment and integrity of the instrument panel, which is crucial for accurate instrument readings 4.

Mounting Gauge

In the context of mounting gauges, the Wear Sleeve allows for the gauge to be securely fastened without undue stress on the mounting points. This ensures that the gauge remains accurately positioned, providing reliable data to the operator 4.

Oil Gauge Mounting

For oil gauge mounting, the 3022316 Wear Sleeve plays a role in maintaining the structural integrity of the mounting system. It prevents wear that could lead to misalignment or failure of the oil gauge, ensuring consistent and accurate oil level readings 4.

Oil Gauge Plumbing

In oil gauge plumbing systems, the Wear Sleeve helps to protect the plumbing connections from wear. This is essential for maintaining the integrity of the oil flow system, ensuring that the gauge provides accurate readings and that the engine receives the proper lubrication 4.

Panel and Engine Instrument

When used in panel and engine instruments, the Wear Sleeve ensures that all moving parts within these instruments operate smoothly. This is vital for the accurate display of engine parameters, contributing to overall engine health and performance 4.

Panel Instrument

Finally, in panel instruments, the 3022316 Wear Sleeve ensures that all components within the panel operate without undue friction or wear. This contributes to the reliability and accuracy of the readings provided by the panel instruments, which are essential for engine monitoring and maintenance 4.

Conclusion

The Cummins 3022316 Wear Sleeve is a critical component in the maintenance and operation of commercial trucks. By providing a protective layer that reduces friction and wear on engine components, it enhances the durability and performance of the engine system. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part. Its compatibility with various engine models and its role in multiple engine systems underscore its importance in ensuring the reliability and efficiency of commercial truck engines.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ ↩ -

Cummins Inc. Operation and Maintenance Manual for X12 CM2670 X121B. Bulletin Number 5504454.

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ ↩ -

Klyde, Michael and VanGelder, Kirk. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.