This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3023511 Oil Cooler Support is a component designed to facilitate the operation of oil coolers in commercial trucks. Its purpose is to maintain the structural integrity and proper positioning of the oil cooler, ensuring that it functions effectively within the engine system. This part plays a role in the overall performance and reliability of the truck’s engine.

Basic Concepts of Oil Cooler Support

Oil cooler supports are integral to the function of oil cooling systems. They help maintain optimal oil temperature by securely holding the oil cooler in place. This ensures that the oil is efficiently cooled as it circulates through the cooler, which is vital for maintaining engine performance and preventing overheating 1. The support also aids in protecting the oil cooler from physical damage and vibrations that could impair its function.

Purpose of the 3023511 Oil Cooler Support

This Cummins part is designed to enhance the operation of a truck’s engine by providing a stable mount for the oil cooler. This support contributes to engine efficiency by ensuring that the oil remains at an optimal temperature, which is crucial for lubrication and reducing wear on engine components. Additionally, it helps extend the longevity of the engine by preventing overheating and associated damage 2.

Key Features

The 3023511 is characterized by several key features that enhance its functionality. It is constructed from durable materials that can withstand the harsh conditions of commercial truck operations. The mounting configuration is designed for easy installation and secure attachment to the truck’s chassis. It is also engineered to integrate seamlessly with other components of the engine cooling system.

Benefits of Using the 3023511 Oil Cooler Support

Employing this part offers several advantages. It contributes to improved engine performance by ensuring that the oil cooler operates efficiently. This support also enhances the durability of the oil cooler and the overall cooling system, leading to reduced maintenance requirements. Additionally, it helps in maintaining consistent oil temperatures, which is beneficial for the engine’s longevity and operational reliability 3.

Installation Process

Installing the 3023511 involves several steps to ensure proper setup. Begin by identifying the correct mounting location on the truck’s chassis. Use the appropriate tools to secure the support in place, following the manufacturer’s guidelines for torque specifications. It is important to verify that the oil cooler is properly aligned and attached to the support. Conduct a final inspection to ensure all connections are secure and there are no obstructions to the oil flow.

Troubleshooting Common Issues

Common issues with this part may include leaks, mounting problems, and performance degradation. To address leaks, inspect the connections and seals for any signs of wear or damage. Mounting issues can often be resolved by re-securing the support or adjusting its position. Performance degradation may require a thorough inspection of the oil cooler and associated components to identify and rectify any underlying problems.

Maintenance Tips

To ensure the longevity and effectiveness of the 3023511, regular maintenance is recommended. This includes periodic inspections to check for any signs of wear or damage. Cleaning the support and associated components can help prevent buildup that may impede performance. Following the manufacturer’s guidelines for inspection intervals and maintenance procedures will help maintain the support’s functionality.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor locations and approximately 7,400 dealer locations. The company’s product portfolio includes engines ranging from 2.8 to 26 liters, as well as related technologies that increase fuel efficiency and reduce emissions.

Compatibility

The Oil Cooler Support, identified by part number 3023511, is a critical component designed to maintain the integrity and efficiency of the engine’s oil cooling system. This support is engineered to withstand the rigors of heavy-duty applications, ensuring that the oil cooler remains securely in place and functions optimally.

N14 MECHANICAL Engines

The Oil Cooler Support part 3023511 is specifically designed to fit seamlessly with the N14 MECHANICAL engines. These engines are known for their robust construction and reliability, often used in demanding applications such as heavy-duty trucks and industrial machinery. The support’s design ensures that it can handle the unique stresses and vibrations associated with these engines, providing a stable platform for the oil cooler.

The integration of the Oil Cooler Support with the N14 MECHANICAL engines is crucial for maintaining the engine’s performance and longevity. By securely mounting the oil cooler, the support helps to regulate oil temperature, preventing overheating and ensuring that the engine operates within its optimal parameters. This is particularly important in high-performance or heavy-duty environments where thermal management is critical.

Role of Part 3023511 Oil Cooler Support in Engine Systems

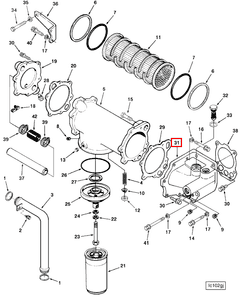

The 3023511 is an integral component in the assembly and functionality of various oil cooling and filtration systems within engine setups. This support structure is designed to securely hold and align the oil cooler and associated components, ensuring efficient operation and maintenance of the engine’s lubrication system.

Integration with Key Components

-

Engine Oil Cooler: The oil cooler support provides a stable mounting point for the engine oil cooler. This ensures that the cooler remains firmly in place, allowing for optimal heat exchange as the lubricant passes through. Proper alignment and secure mounting are essential for maintaining the cooler’s efficiency and longevity.

-

Lube Oil Cooler and Lubricating Oil Assembly Cooler: Similar to the engine oil cooler, the lube oil cooler and lubricating oil assembly cooler benefit from the secure mounting provided by the oil cooler support. This stability is vital for consistent performance, as these coolers play a significant role in maintaining the viscosity and temperature of the lubricating oil.

-

Oil Filter / Cooler: The oil cooler support also facilitates the integration of oil filter/cooler units. By providing a robust attachment point, it ensures that the filter/cooler can operate without undue stress or movement, which could otherwise compromise its filtering efficiency and cooling capabilities.

-

Lubricating Oil Filter and Lubricating Oil Filter / Cooler: These components rely on the oil cooler support for proper installation and operation. The support ensures that the filters are correctly positioned to allow for effective filtration of contaminants while also aiding in the cooling process.

-

Lubricating Pump Conversion Kit: When utilizing a lubricating pump conversion kit, the oil cooler support helps in aligning the pump with the cooler and filter systems. This alignment is necessary for the pump to efficiently circulate the lubricant through the system, ensuring that all components receive adequate cooling and filtration.

-

Bypass Valve: The oil cooler support indirectly supports the function of the bypass valve by maintaining the structural integrity of the oil cooling and filtration system. A stable system allows the bypass valve to operate correctly, managing oil flow and pressure as needed to protect the engine from damage due to restricted oil flow.

Conclusion

In summary, the 3023511 plays a significant role in the effective functioning of various oil cooling and filtration components within engine systems. Its design ensures that these critical elements are securely mounted and properly aligned, contributing to the overall efficiency and reliability of the engine’s lubrication system.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.