This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

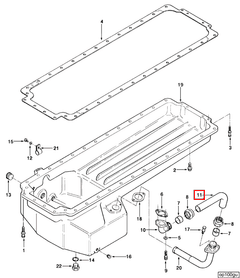

The Lubricating Oil Transfer Tube, identified by Part #3029911, is a component manufactured by Cummins, a leader in diesel engine technology. This part is integral to the maintenance of heavy-duty trucks, facilitating the efficient operation of the engine’s lubrication system.

Function and Operation

The Lubricating Oil Transfer Tube operates within the lubrication system of a truck engine by transferring oil to various engine components. It ensures that oil is distributed evenly, which is vital for the smooth operation and longevity of the engine. The tube connects to the oil pump and extends to critical areas requiring lubrication, such as bearings and pistons, thereby playing a role in maintaining the engine’s mechanical efficiency 1.

Purpose of the Lubricating Oil Transfer Tube

The specific role of the Lubricating Oil Transfer Tube is to ensure that engine parts receive adequate lubrication. This contributes to the engine’s efficiency by reducing friction between moving parts and helps in prolonging the engine’s operational life by preventing wear and tear 2.

Key Features

The Lubricating Oil Transfer Tube is designed with several features that enhance its performance. It is constructed from durable materials to withstand the high pressures and temperatures within the engine. The tube includes precise connection types that ensure a secure fit within the engine’s lubrication system. Unique design elements may include reinforced sections to prevent kinking and ensure a consistent flow of oil.

Benefits

The advantages provided by the Lubricating Oil Transfer Tube include improved lubrication distribution across the engine, which enhances overall engine performance. By ensuring that all parts are properly lubricated, the tube contributes to the engine’s efficiency and can lead to potential cost savings through extended engine life and reduced maintenance needs 3.

Installation Considerations

For the proper installation of the Lubricating Oil Transfer Tube, it is important to follow guidelines that ensure compatibility with various engine models. Maintaining the integrity of seals during installation is crucial to prevent leaks and ensure the tube functions correctly within the lubrication system.

Troubleshooting Common Issues

Typical problems associated with the Lubricating Oil Transfer Tube may include leaks or blockages. Diagnostic procedures should be employed to identify the source of the issue, which may involve inspecting connections for tightness and checking for any signs of wear or damage to the tube itself. Repair procedures will vary depending on the specific issue identified.

Maintenance Tips

Regular maintenance practices are recommended to ensure the Lubricating Oil Transfer Tube remains in optimal condition. This includes periodic inspection intervals to check for any signs of wear, damage, or leaks. Cleaning procedures should be followed to remove any contaminants that may accumulate within the tube, ensuring that the lubrication system operates efficiently.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the industry, providing reliable and efficient power solutions for various applications.

Compatibility with Cummins Engines

N14 CELECT and N14 MECHANICAL Engines

The N14 CELECT and N14 MECHANICAL engines, both part of the Cummins N-Series family, are known for their robust performance and reliability. The 3029911 Lubricating Oil Transfer Tube is specifically engineered to fit seamlessly within these engines. It ensures that oil is efficiently transferred from the oil sump to the engine’s upper sections, maintaining optimal lubrication levels across the engine’s critical components.

NH/NT 855 Engines

The NH/NT 855 engines, another prominent series in Cummins’ lineup, also benefit from the use of the 3029911 Lubricating Oil Transfer Tube. This part is integral to the engine’s lubrication system, ensuring that oil is distributed evenly and effectively throughout the engine. Its design allows for smooth operation and longevity of the engine by preventing metal-to-metal contact and reducing friction.

Importance of the Lubricating Oil Transfer Tube

The 3029911 Lubricating Oil Transfer Tube is essential for maintaining the health and efficiency of the engines it is used in. By ensuring that oil is properly circulated, it helps to:

- Reduce Friction: Minimizes wear on engine components.

- Prevent Overheating: Maintains optimal operating temperatures.

- Enhance Performance: Ensures that the engine runs smoothly and efficiently.

- Extend Engine Life: Reduces the likelihood of engine failure due to lubrication issues.

This part is a testament to Cummins’ commitment to providing high-quality components that enhance engine performance and reliability.

Role of Part 3029911 Lubricating Oil Transfer Tube in Engine Systems

The lubricating oil transfer tube, specifically part 3029911, is an integral component in the efficient operation of engine systems. Its primary function is to facilitate the smooth transfer of lubricating oil from the oil pan to various engine components that require lubrication.

Integration with Key Components

Lubricating Oil Suction Tube

The lubricating oil transfer tube works in conjunction with the lubricating oil suction tube. As the engine operates, the suction tube draws oil from the oil pan. The transfer tube then ensures this oil is efficiently routed to the engine’s lubrication system, maintaining consistent oil flow and pressure.

Oil Pan

Positioned at the engine’s lower section, the oil pan serves as the reservoir for lubricating oil. The transfer tube connects to the oil pan, allowing for the seamless extraction of oil. This connection ensures that the oil is readily available for circulation throughout the engine.

Pan

Often synonymous with the oil pan, the pan component stores a sufficient volume of oil to meet the engine’s lubrication demands. The transfer tube’s role is to draw oil from this storage area and distribute it to critical engine parts, ensuring they remain well-lubricated and operate smoothly.

Oil

The lubricant itself, oil is vital for reducing friction between moving parts within the engine. The transfer tube’s efficient design ensures that oil is consistently and reliably delivered to where it is needed most, enhancing the engine’s performance and longevity.

Conclusion

In summary, the 3029911 Lubricating Oil Transfer Tube plays a significant role in the lubrication process by ensuring that oil is effectively transferred from the oil pan to the engine’s lubrication system, supporting the overall functionality and efficiency of the engine. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.