This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

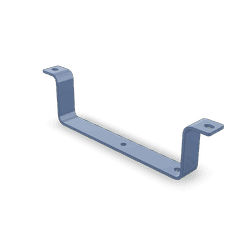

The Oil Tube Bracket 3031998, manufactured by Cummins, is a component designed to facilitate the secure routing of oil tubes within the engine system of heavy-duty trucks. This Cummins part plays a significant role in maintaining the integrity and efficiency of the oil circulation system, ensuring that oil is effectively distributed to various engine components. Cummins, a renowned name in diesel engine manufacturing, provides this bracket as part of its commitment to quality and innovation in the automotive industry.

Function and Operation

The Oil Tube Bracket 3031998 operates by securing and routing oil tubes within the truck’s engine system. It ensures that oil tubes are held in place and follow the correct path, which is vital for the efficient operation of the engine. By maintaining the proper alignment and tension of the oil tubes, this part helps in preventing oil leaks and ensuring a consistent flow of oil to critical engine components.

Key Features

The Oil Tube Bracket 3031998 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design of the bracket includes precise mounting points and secure clamps that hold the oil tubes firmly in place. Additionally, the bracket is engineered to accommodate various oil tube sizes and configurations, providing versatility in its application.

Benefits

The use of the Oil Tube Bracket 3031998 offers several advantages. It improves oil flow management by ensuring that oil tubes are correctly positioned and secured, which contributes to the overall efficiency of the engine. The durable construction of the bracket enhances its longevity, reducing the need for frequent replacements. Furthermore, by maintaining a secure and leak-free oil system, the bracket plays a role in supporting the engine’s performance and reliability.

Installation Process

Installing the Oil Tube Bracket 3031998 involves several steps to ensure proper placement and function. Begin by identifying the correct mounting locations on the engine. Use the appropriate tools to secure the bracket in place, ensuring that it is aligned correctly with the oil tubes. Carefully route the oil tubes through the bracket, making sure they are snugly fitted within the clamps. Finally, double-check all connections to confirm that the oil tubes are secure and there are no potential points of leakage.

Maintenance and Troubleshooting

Regular maintenance of the Oil Tube Bracket 3031998 is important to ensure its continued performance and longevity. Inspect the bracket and oil tubes during routine engine checks for signs of wear, corrosion, or damage. Tighten any loose clamps and replace any worn or damaged components as necessary. Common issues may include oil leaks, which can often be traced back to improperly secured oil tubes or damaged brackets. Addressing these issues promptly can prevent more significant problems down the line.

Compatibility and Applications

The Oil Tube Bracket 3031998 is designed for use in specific types of engines and truck models. It is important to consult the manufacturer’s guidelines for compatibility information to ensure the bracket is suitable for your application. Proper application of this Cummins part can enhance the performance and reliability of the engine system in compatible vehicles.

Safety Considerations

When working with the Oil Tube Bracket 3031998, it is important to observe several safety guidelines. Ensure the engine is cool and turned off before beginning any installation or maintenance procedures. Use the appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from potential hazards. Follow all manufacturer instructions carefully to avoid damage to the bracket or engine components.

Cummins Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and natural gas engines. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s commitment to excellence is evident in its wide range of products, including the Oil Tube Bracket 3031998, which is designed to meet the demanding requirements of heavy-duty truck engines.1

Cummins Oil Tube Bracket 3031998 Compatibility

The Cummins Oil Tube Bracket part number 3031998 is designed to fit a variety of engines, ensuring a secure and efficient oil tube connection. This bracket is compatible with the following engines:

GTA38 G CMEICS G116C

The Oil Tube Bracket 3031998 is engineered to fit seamlessly with the GTA38 G CMEICS G116C engine, providing a robust mounting solution for the oil tube.

K38, K50, QSK38 CM2150 MCRS, QSK38 CM850 MCRS

This bracket is also suitable for the K38 and K50 engines, as well as the QSK38 CM2150 MCRS and QSK38 CM850 MCRS engines. It ensures that the oil tube is securely fastened, maintaining optimal engine performance.

QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

Additionally, the Oil Tube Bracket 3031998 is compatible with the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines. It provides a reliable connection point for the oil tube, ensuring that the engine operates smoothly and efficiently.

Integration with Lub Oil Plumbing and Tubing

The Oil Tube Bracket is primarily used to secure and support the Lub Oil Plumbing and Lub Oil Tubing. It ensures that these components are correctly aligned and maintained in position, which is vital for the uninterrupted flow of lubricating oil throughout the engine system. The bracket helps in reducing vibrations and potential wear on the tubing, thereby enhancing the longevity and performance of the oil system.

Connection to Oil Suction Components

In the context of Oil Suction, the bracket is instrumental in mounting and stabilizing the Oil Suction Tube and associated mounting components. It provides a secure attachment point for the Suction Mounting Tube, ensuring that the oil suction process is efficient and consistent. This is particularly important in maintaining the proper oil levels and pressure within the engine, which is essential for optimal engine performance.

Role in Engine Oil and Lubricating Oil Suction

The bracket also plays a part in the overall Engine Oil and Lubricating Oil Suction system. By securely holding the oil suction components in place, it aids in the effective suction of oil from the Pan, which is then circulated through the engine for lubrication purposes. This ensures that all moving parts within the engine receive the necessary lubrication, reducing friction and wear.

Support for Cooler and EBM-PAN Integration

Furthermore, the Oil Tube Bracket assists in the integration of the Cooler and EBM-PAN within the engine system. It helps in maintaining the structural integrity of the oil flow path from the Pan to the Cooler, and subsequently back to the engine. This is important for the thermal management of the engine oil, ensuring that the oil remains at an optimal temperature for efficient engine operation.

Conclusion

In summary, the Oil Tube Bracket 3031998 is a vital component in the engine oil system, providing necessary support and stability to various oil-related components. Its role in ensuring the proper alignment and secure mounting of these components is essential for the efficient and reliable operation of the engine.

-

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.