3035197

Oil Gauge Tube End

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Oil Gauge Tube End, identified by part number 3035197, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is integral to the functioning of heavy-duty trucks, ensuring that the engine operates efficiently and reliably. Cummins is renowned for its commitment to quality and innovation, providing parts that meet the demanding requirements of heavy-duty applications 1.

Function and Operation

The Oil Gauge Tube End operates within the engine system by facilitating the measurement of oil levels. It is connected to the oil gauge, allowing for the accurate monitoring of oil levels within the engine. This part ensures that the engine receives the proper lubrication it requires to function optimally. By maintaining the correct oil levels, the Oil Gauge Tube End helps in reducing friction between moving parts, which is vital for the engine’s performance and longevity 2.

Purpose of the Oil Gauge Tube End

The Oil Gauge Tube End plays a specific role in the operation of a truck by contributing to engine performance and longevity. It ensures that the engine is adequately lubricated, which is crucial for minimizing wear and tear on engine components. Proper lubrication leads to smoother operation, reduced maintenance needs, and extended engine life. Additionally, by providing accurate oil level readings, it allows for timely oil changes and maintenance, further enhancing engine reliability 3.

Key Features

The Oil Gauge Tube End is designed with several key features that enhance its functionality. It is typically made from durable materials that can withstand the high temperatures and pressures within an engine. The design of the tube end ensures a secure fit within the engine system, preventing leaks and ensuring accurate oil level readings. Its construction is tailored to endure the rigors of heavy-duty use, ensuring long-lasting performance.

Benefits

Using the Oil Gauge Tube End offers several benefits. It contributes to improved engine efficiency by ensuring that the engine is properly lubricated. This reduces friction and wear on engine components, leading to enhanced durability. The reliable performance of the Oil Gauge Tube End means that truck operators can have confidence in their vehicle’s engine health, reducing the likelihood of unexpected breakdowns.

Installation Process

Installing the Oil Gauge Tube End requires careful attention to detail to ensure proper function. Begin by ensuring the engine is cool and the oil has been drained. Locate the oil gauge sender unit and disconnect any electrical connections. Remove the old tube end, taking note of its orientation. Install the new Oil Gauge Tube End, ensuring it is securely fitted. Reconnect any electrical connections and refill the engine with the appropriate oil. Finally, check the oil level and ensure the gauge is reading accurately.

Troubleshooting Common Issues

Common issues with the Oil Gauge Tube End may include inaccurate oil level readings or leaks. If the gauge reads incorrectly, check the connection to ensure it is secure and free from corrosion. For leaks, inspect the fitting for proper installation and ensure there are no cracks or damage to the tube end. Addressing these issues promptly can prevent more significant problems and ensure the engine continues to operate efficiently.

Maintenance Tips

To maintain the Oil Gauge Tube End and ensure optimal performance, regular inspections are recommended. Check the connection and fitting for signs of wear or damage during routine oil changes. Ensure the gauge is reading accurately and address any discrepancies immediately. Following the manufacturer’s recommended service intervals for oil changes and inspections will help maintain the integrity of the Oil Gauge Tube End and the engine as a whole.

Cummins Engine Compatibility with Oil Gauge Tube End Part 3035197

The Cummins Oil Gauge Tube End part number 3035197 is a critical component for monitoring oil levels in various Cummins engine models. This part is designed to fit seamlessly into the oil systems of the following engines:

B6.7 Series

- B6.7 CM2670

- ISB/ISD6.7 CM2150 SN

G Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

- KTA19GC

- KTA19GC CM558

L Series

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

M Series

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

N Series

- N14 CELECT

- N14 CELECT PLUS

ISM Series

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

ISF Series

- ISF3.8 CM2220 AN

ISBE Series

- ISBE CM800

- ISBE4 CM850

K Series

- K19

- K38

- K50

The Oil Gauge Tube End part 3035197 is engineered to ensure compatibility with these engines, providing a reliable method for oil level monitoring. This part is essential for maintaining the health and performance of the engines by ensuring that oil levels are within the optimal range.

Role of Part 3035197 Oil Gauge Tube End in Engine Systems

The part 3035197 Oil Gauge Tube End is integral to the accurate measurement and monitoring of oil levels within various engine systems. It interfaces with several components to ensure the oil gauge provides reliable readings, which is essential for maintaining engine health and performance.

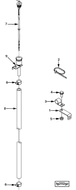

Interaction with Oil Gauge and Mounting Components

The Oil Gauge Tube End connects to the Oil Gauge and Mounting Tube, forming a sealed pathway for oil to travel from the oil pan to the gauge. This setup allows for precise measurement of the oil level, ensuring that the Oil Gauge (Painted) Tube displays the correct reading. The Oil Gauge Bayonet fitting, often part of this assembly, secures the connection, preventing leaks and ensuring consistent pressure within the system.

Integration with Dipstick and Tube Assemblies

In systems where a dipstick is used alongside or instead of an oil gauge, the Oil Gauge Tube End may interface with the Dipstick and Tube Arrangement. This integration allows for dual monitoring methods, providing redundancy and increased accuracy in oil level assessment. The Dipstick and Oil Fill Arrangement may also be connected, enabling simultaneous oil filling and level checking, which is particularly useful during maintenance procedures.

Connection to Oil Pan and Turbocharger

The Oil Gauge Tube End is often linked to the Oil Pan and Dipstick, ensuring that the oil level within the pan is accurately reflected on the gauge. In turbocharged engines, the connection extends to the Turbocharger, where oil levels must be meticulously monitored to prevent lubrication failures that could lead to catastrophic engine damage. The Oil Gauge Tube End ensures that the oil gauge provides real-time data on oil levels, aiding in the prompt detection of any anomalies.

Role in Aftercooler Conversion Kit and Cylinder Block Cover

In engines equipped with an Aftercooler Conversion Kit, the Oil Gauge Tube End plays a role in monitoring oil levels that are critical for the efficient operation of the aftercooler. Similarly, in systems with a Cylinder Block Cover, the Oil Gauge Tube End ensures that oil levels within the cylinder block are consistently monitored, contributing to the overall lubrication and cooling efficiency of the engine.

Supporting Oil Fill and Arrangement Components

The Oil Gauge Tube End also supports the Oil Fill and Arrangement components by providing a reliable method for checking oil levels during the filling process. This is particularly important in ensuring that the engine is neither overfilled nor underfilled, both of which can lead to performance issues and potential damage.

Comprehensive Monitoring with EBM: Gauge, Oil Level, Kit

Finally, the Oil Gauge Tube End is a key component in the EBM: Gauge, Oil Level, Kit, which is designed for comprehensive engine monitoring. This kit often includes various sensors and gauges, and the Oil Gauge Tube End ensures that the oil level gauge within this system operates accurately, providing engineers and mechanics with vital data for engine diagnostics and maintenance.

Conclusion

The Oil Gauge Tube End part 3035197 by Cummins is a vital component in the maintenance and operation of heavy-duty engines. Its role in accurately monitoring oil levels ensures that engines remain lubricated, reducing friction and wear, and contributing to overall engine efficiency and longevity. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to maximize the benefits of this Cummins part. By ensuring the correct oil levels, the Oil Gauge Tube End supports the reliable performance of engines, making it an indispensable part for truck operators and mechanics alike.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.