This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

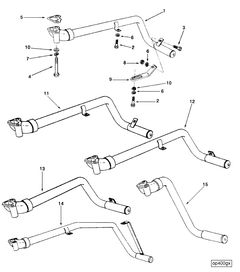

The Lubricating Oil Suction Tube, identified by Part #3035301, is a component manufactured by Cummins. This tube is integral to the engine lubrication system, facilitating the efficient transfer of oil from the sump to the oil pump. Cummins, a well-established name in the commercial truck industry, ensures that this component meets rigorous standards for performance and durability 1.

Function and Operation

The Lubricating Oil Suction Tube operates by drawing oil from the sump, the lowest part of the engine where oil collects, and delivering it to the oil pump. This process is vital for maintaining a consistent supply of lubricant to the engine’s moving parts. The tube’s design allows for a smooth and uninterrupted flow of oil, which is crucial for the effective lubrication of engine components, thereby reducing friction and wear 2.

Key Features

The Lubricating Oil Suction Tube is constructed from high-quality materials, ensuring durability and resistance to the harsh conditions within the engine compartment. Its design includes a specific tube diameter that optimizes oil flow while minimizing the risk of air ingestion, which can lead to inefficient lubrication. Unique design elements, such as reinforced sections and precise manufacturing tolerances, enhance the tube’s performance and longevity.

Benefits

The advantages of the Lubricating Oil Suction Tube include improved oil flow, which ensures that the engine receives a steady supply of lubricant. This consistent flow helps in reducing the risk of air ingestion, which can cause cavitation in the oil pump and lead to inefficient lubrication. Enhanced engine lubrication, in turn, contributes to the overall efficiency and longevity of the engine 3.

Installation and Compatibility

Proper installation of the Lubricating Oil Suction Tube is crucial for its effective operation within the engine lubrication system. Specific requirements and considerations must be observed to ensure a secure and effective fit. These may include alignment with other components, securing the tube in place to prevent movement, and ensuring that connections are tight to avoid leaks.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the optimal performance of the Lubricating Oil Suction Tube. These may include regular inspections for signs of wear or damage, cleaning to remove any contaminants that may obstruct oil flow, and replacing the tube if it shows signs of significant degradation. Troubleshooting common issues, such as reduced oil flow or leaks, may involve checking for proper installation, inspecting connections for tightness, and ensuring that the tube is free from obstructions.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality engines and components. With a rich history of innovation and a broad range of product offerings, Cummins has established a strong reputation for reliability and performance. The company’s commitment to excellence is evident in its components, including the Lubricating Oil Suction Tube, which is designed to meet the demanding requirements of modern engines.

Cummins Lubricating Oil Suction Tube (Part 3035301) in Engine Applications

The Cummins Lubricating Oil Suction Tube, identified by part number 3035301, is a critical component in the engine’s lubrication system. This part is designed to facilitate the suction of oil from the oil pan to the oil pump, ensuring a continuous and efficient flow of lubrication throughout the engine.

Application in K19 Engines

The K19 engine series, known for its robust performance and reliability, integrates the 3035301 oil suction tube to maintain optimal lubrication. This part is engineered to withstand the high pressures and temperatures typical of diesel engines, ensuring longevity and consistent engine operation.

Grouping with Other Cummins Engines

The 3035301 oil suction tube is also compatible with various other Cummins engine models. These engines, while differing in specific configurations and applications, share a common requirement for effective lubrication. The use of this part across multiple engine types underscores its versatility and importance in maintaining engine health.

Importance of Proper Installation

Correct installation of the 3035301 oil suction tube is essential for the engine’s performance. Any misalignment or damage to this component can lead to inadequate oil flow, potentially causing engine damage. Technicians should ensure that the tube is securely attached and free from leaks to prevent oil starvation and associated engine issues.

Maintenance and Replacement

Regular maintenance checks should include inspecting the 3035301 oil suction tube for signs of wear or damage. Prompt replacement of a compromised tube is crucial to avoid engine damage and ensure the longevity of the engine’s lubrication system.

Role of Part 3035301 Lubricating Oil Suction Tube in Engine Systems

The lubricating oil suction tube, identified by part number 3035301, is integral to the efficient operation of engine systems, particularly in the context of oil management and circulation. This component is designed to facilitate the smooth and consistent flow of oil from the oil pan to the engine’s lubrication system.

Integration with the Oil Pan

The oil pan serves as the reservoir for the engine’s lubricating oil. Positioned at the bottom of the engine, it collects oil that has circulated through the engine and provides a sump from which oil can be drawn. The lubricating oil suction tube connects to the oil pan, typically near the bottom where the oil level is highest. This strategic placement ensures that the tube can effectively draw oil, even when the oil level is low.

Oil Circulation Process

Once connected to the oil pan, the suction tube plays a key role in the oil circulation process. It draws oil from the pan and transports it to the oil pump. The oil pump then pressurizes the oil and distributes it throughout the engine to lubricate moving parts, reduce friction, and dissipate heat.

Ensuring Consistent Oil Flow

The design of the lubricating oil suction tube is such that it minimizes turbulence and ensures a steady flow of oil to the pump. This consistent flow is essential for maintaining optimal engine performance and longevity. Any disruption in the oil flow can lead to inadequate lubrication, increased wear on engine components, and potentially catastrophic engine failure.

Maintenance and Inspection

Regular inspection of the lubricating oil suction tube is recommended to ensure it remains free of obstructions and is not damaged. Any leaks or blockages in the tube can impede oil flow, leading to inefficient lubrication and possible engine damage.

Conclusion

In summary, the Lubricating Oil Suction Tube (part 3035301) is a vital component in the engine’s lubrication system, working in conjunction with the oil pan to ensure a reliable and consistent supply of oil to the engine’s critical moving parts. Its proper installation, maintenance, and timely replacement are essential for the engine’s performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.