This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

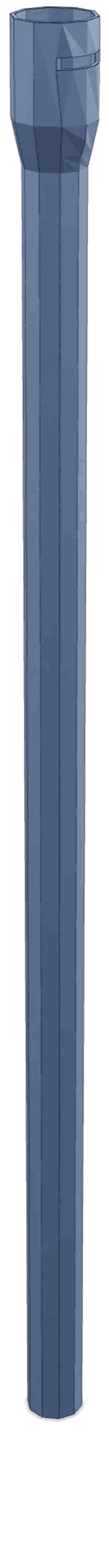

The 3041212 Flexible Hose Assembly, manufactured by Cummins, is a component designed for use in commercial trucks. It serves a role in the operation of these vehicles by facilitating the transfer of fluids between various parts of the truck’s system. Cummins, a well-established manufacturer in the industry, produces this hose assembly to meet the demanding requirements of heavy-duty applications.

Basic Concepts of Flexible Hose Assemblies

Flexible hose assemblies are components used in fluid transfer systems to connect different parts of the system, allowing for the movement and transfer of fluids such as coolant, fuel, or hydraulic fluid. In the context of heavy-duty trucks, these assemblies must withstand high pressures, temperature fluctuations, and mechanical stress. They provide a flexible connection that accommodates the movement and vibration inherent in truck operations, ensuring a reliable and efficient fluid transfer system 1.

Purpose of the 3041212 Flexible Hose Assembly

The 3041212 Flexible Hose Assembly is specifically designed to handle the transfer of fluids within a truck’s system. It connects critical components, ensuring the smooth operation of the truck’s fluid systems. The assembly is engineered to manage various types of fluids, contributing to the overall efficiency and reliability of the truck’s performance.

Key Features

The 3041212 Flexible Hose Assembly is constructed with high-quality materials that offer flexibility and durability. Its design includes features that enhance performance, such as reinforced ends for secure connections and a flexible body that can accommodate the dynamic movements of a truck. These characteristics ensure the assembly can withstand the rigors of heavy-duty use while maintaining a reliable seal 2.

Benefits

The 3041212 Flexible Hose Assembly offers several advantages. It provides improved reliability in fluid transfer systems, ease of installation due to its flexible design, and a reduction in maintenance requirements compared to rigid hose solutions. Additionally, its construction includes safety features that help prevent leaks and ensure the safe operation of the truck’s fluid systems.

Installation and Integration

Proper installation of the 3041212 Flexible Hose Assembly involves following manufacturer guidelines to ensure a secure and efficient connection. Best practices include using the necessary tools for a snug fit, verifying compatibility with other truck components, and integrating the assembly in a manner that accommodates the truck’s movement and operational demands.

Troubleshooting Common Issues

Common issues with flexible hose assemblies may include leaks, wear and tear, and connection failures. Troubleshooting these problems involves inspecting the assembly for signs of damage, ensuring connections are secure, and replacing the assembly if necessary. Regular checks can help identify potential issues before they lead to more significant problems 3.

Maintenance Tips

To ensure the longevity and efficient operation of the 3041212 Flexible Hose Assembly, regular maintenance is recommended. This includes routine inspections for signs of wear or damage, cleaning the assembly to remove any buildup that could affect performance, and following manufacturer guidelines for replacement intervals. Adhering to these practices helps maintain the assembly’s performance and reliability.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a history of producing high-quality components for the automotive and heavy-duty truck industries. The company is known for its commitment to innovation, quality, and customer satisfaction. Cummins’ reputation in the industry is built on its dedication to developing products that meet the rigorous demands of commercial applications, ensuring reliability and performance in every component it manufactures 4.

Flexible Hose Assembly 3041212 by Cummins

The Flexible Hose Assembly 3041212, manufactured by Cummins, is a component designed to ensure seamless fluid transfer within various engine systems. This part is engineered to provide flexibility and durability, accommodating the dynamic movements and vibrations inherent in engine operations.

In the context of the K19 engine, the Flexible Hose Assembly 3041212 plays a role in maintaining the integrity of the engine’s fluid systems. It is specifically designed to fit into the K19 engine’s architecture, ensuring that it can withstand the high pressures and temperatures typical of engine environments. The assembly’s flexibility allows it to connect different engine components without compromising the system’s performance, thereby enhancing the engine’s overall reliability and efficiency.

For engines within the same group as the K19, the Flexible Hose Assembly 3041212 is engineered to offer a universal fit. This ensures that the part can be seamlessly integrated into various engine models, providing a consistent performance across different engine types. The design of this assembly is such that it can adapt to the specific requirements of each engine, ensuring optimal functionality and longevity.

Role of Part 3041212 Flexible Hose Assembly in Engine Systems

The 3041212 Flexible Hose Assembly is a component in the integration of various engine systems, facilitating the seamless transfer of fluids and ensuring the efficient operation of critical engine functions.

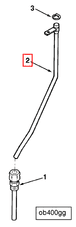

In the context of the gauge system, the Flexible Hose Assembly connects the gauge to the engine’s fluid lines, allowing for the accurate measurement and display of fluid levels and pressures. This connection is vital for monitoring engine health and performance, as it enables real-time data collection that informs maintenance and operational decisions.

When considering the oil level system, the Flexible Hose Assembly plays a role in linking the oil level sensor to the engine’s oil passages. This ensures that the sensor can accurately detect the oil level within the engine, providing data for maintaining proper lubrication and preventing engine damage due to low oil levels.

In the oil gauge tube system, the Flexible Hose Assembly serves as a conduit between the oil gauge and the engine’s oil supply. This connection allows for the precise measurement of oil pressure, which is a key indicator of engine condition. Consistent oil pressure is necessary for optimal engine performance, and the Flexible Hose Assembly ensures that the oil gauge receives accurate readings, enabling timely interventions if pressure levels fall outside the normal range.

Overall, the 3041212 Flexible Hose Assembly is integral to the reliable operation of these engine systems, ensuring that fluid levels and pressures are accurately monitored and maintained.

Conclusion

The 3041212 Flexible Hose Assembly by Cummins is a critical component for the efficient and reliable operation of commercial trucks and heavy-duty engines. Its design and construction ensure it can withstand the demanding conditions of these applications, providing a flexible and durable solution for fluid transfer. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Rendle, Steve, and Randall, Martynn. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.