This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

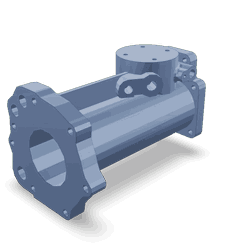

The Oil Cooler Housing 3052210 by Cummins is a component designed to facilitate the cooling of engine oil in heavy-duty trucks. This housing is integral to the operation of these vehicles, ensuring that the engine oil remains at an optimal temperature, which is vital for the efficient and reliable performance of the engine. Cummins, a well-regarded manufacturer in the automotive industry, produces this part with a focus on durability and performance 3.

Function and Operation of Oil Cooler Housing

The Oil Cooler Housing 3052210 operates within the truck’s lubrication system by housing the oil cooler. The oil cooler’s role is to dissipate excess heat from the engine oil, which is circulated through the cooler by the oil pump. As the oil passes through the cooler, it transfers heat to the surrounding air, which is facilitated by the design of the housing. This process helps maintain the oil at a temperature that ensures proper viscosity for lubrication, reducing wear on engine components 1.

Purpose of the Oil Cooler Housing

The specific role of the 3052210 Oil Cooler Housing in a truck’s operation is to provide a secure and efficient environment for the oil cooler. By maintaining optimal oil temperature, it contributes to engine performance and longevity. This is achieved by ensuring that the oil remains within the desired temperature range, which is crucial for the engine’s lubrication system to function effectively 2.

Key Features

The 3052210 Oil Cooler Housing is characterized by several key features that enhance its functionality. It is constructed from high-quality materials that offer resistance to corrosion and wear. The design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the housing is engineered to maximize the efficiency of the oil cooling process, with features that promote optimal airflow and heat dissipation.

Benefits of Using the 3052210 Oil Cooler Housing

Utilizing the 3052210 Oil Cooler Housing offers several advantages. It contributes to improved engine efficiency by ensuring that the oil remains at an optimal temperature, which reduces the risk of overheating and associated engine damage. Furthermore, it extends the lifespan of engine components by providing consistent and effective cooling, which is particularly beneficial in heavy-duty applications where engines are subjected to high loads and temperatures. Overall, the housing enhances the performance and reliability of the truck.

Installation Considerations

When installing the 3052210 Oil Cooler Housing, it is important to follow guidelines to ensure proper fitment and function. Compatibility with various truck models and engine types should be verified to ensure optimal performance. Careful attention to the manufacturer’s instructions during installation will help maintain the integrity of the cooling system and ensure the housing operates as intended.

Maintenance and Troubleshooting

Regular maintenance of the 3052210 Oil Cooler Housing is recommended to ensure its longevity and efficiency. This includes checking for signs of wear or damage, ensuring connections are secure, and verifying that the cooling system is functioning correctly. Common issues may include leaks or reduced cooling efficiency, which can often be addressed by inspecting and tightening connections or cleaning the housing to remove any obstructions.

Cummins: A Brief Overview

Cummins is a manufacturer with a strong reputation in the automotive industry, known for producing high-quality components. With a history of innovation and commitment to excellence, Cummins has established itself as a leader in the production of engines and related parts. Their products are designed with a focus on reliability, performance, and durability, making them a preferred choice for heavy-duty applications 3.

Cummins Oil Cooler Housing Part 3052210 Compatibility

The Cummins Oil Cooler Housing part number 3052210 is designed to fit a variety of engine models, ensuring efficient oil cooling across different applications. This part is engineered to meet the specific needs of the engines it supports, providing reliable performance and durability.

G855 and NH/NT 855 Engines

The Oil Cooler Housing part 3052210 is compatible with the G855 and NH/NT 855 engines. These engines benefit from the housing’s design, which facilitates effective heat transfer and maintains optimal oil temperatures, crucial for engine longevity and performance.

N14 MECHANICAL and QSNT14 CM876 N102 Engines

Similarly, the part fits the N14 MECHANICAL and QSNT14 CM876 N102 engines. For these engines, the housing ensures that the oil is adequately cooled, preventing overheating and reducing wear on engine components. The design of the housing is tailored to integrate seamlessly with these engine models, providing a robust solution for oil cooling.

Integration and Performance

The integration of the Oil Cooler Housing part 3052210 with the listed engines is straightforward, thanks to its standardized design and compatibility with multiple engine types. This part is crucial in maintaining the efficiency and reliability of the engines it supports, ensuring that oil remains at the appropriate temperature for optimal engine operation.

Role of Part 3052210 Oil Cooler Housing in Engine Systems

The Part 3052210 Oil Cooler Housing is an integral component in various engine oil cooling systems, ensuring optimal performance and longevity of the engine. This housing is designed to encapsulate and protect the oil cooler, which is responsible for maintaining the engine oil at an ideal temperature.

In systems involving the cooler, the oil cooler housing provides a secure environment for the cooler to operate efficiently. It interfaces with the engine oil system, allowing for the circulation of oil through the cooler to dissipate excess heat.

When integrated with the cooler lubricating oil filter, the housing ensures that the filtered oil is cooled before it is reintroduced into the engine, enhancing the filtration process and prolonging the life of the filter.

In EBM: cooler applications, the housing plays a role in maintaining the structural integrity of the cooler, protecting it from external elements and ensuring consistent cooling performance.

The engine oil cooler relies on the housing to create a sealed environment, preventing leaks and ensuring that the cooling process is effective. This is particularly important in high-stress environments where engine oil temperatures can rise rapidly.

In assemblies such as the filter & cooler assy, the housing acts as a bridge between the filter and the cooler, ensuring that the oil is both clean and at the correct temperature before it reaches the engine components.

For systems utilizing a full flow oil filter, the housing ensures that the oil passes through the cooler after filtration, optimizing the oil’s condition before it lubricates the engine parts.

In lubricating oil systems, the housing is essential for protecting the lubricating oil cooler and ensuring that the oil remains within the desired temperature range, which is vital for reducing wear and tear on engine components.

The lubricating oil cooler (top level assembly) benefits from the housing by maintaining a consistent cooling environment, which is critical for the assembly’s overall performance.

In conversion kits such as the lubricating oil cooler conversion kit, the housing provides a necessary adaptation point, allowing for the integration of new cooling technologies into existing systems.

The lubricating oil cooler housing itself is a specialized component that directly encases the cooler, offering protection and structural support.

Kits like the lubricating oil cooler kit often include the housing as a key component, ensuring that the cooler is installed correctly and functions as intended.

The lubricating oil filter and lubricating oil filter / cooler assemblies both rely on the housing to maintain a secure connection between the filter and the cooler, ensuring that the oil is both filtered and cooled effectively.

Finally, in systems with a lube oil cooler, the housing ensures that the cooler operates within a protected environment, maintaining the efficiency of the cooling process and the quality of the lube oil.

Conclusion

The 3052210 Oil Cooler Housing by Cummins is a critical component in the maintenance of engine oil temperature, ensuring the efficient operation and longevity of heavy-duty truck engines. Its design, compatibility with various engine models, and the benefits it provides in terms of engine performance and reliability make it a valuable part in the automotive industry.

-

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Cummins. (n.d.). Generator Set QSK60G CM700, Bulletin Number 4021395, Operation and Maintenance Manual.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.