3054335

Tur Oil Drain Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tur Oil Drain Tube, identified by part number 3054335, is a component manufactured by Cummins, a leading name in diesel engine technology. This tube is integral to the maintenance routines of heavy-duty trucks, facilitating efficient oil drainage from the engine. Cummins’ reputation for quality and innovation underscores the reliability and performance of this part 1.

Function and Operation

The Tur Oil Drain Tube operates as a conduit for oil drainage within the truck’s engine system. It is designed to allow for the smooth and complete removal of oil during maintenance routines, ensuring that the engine operates with fresh lubricant. This process is vital for maintaining the engine’s efficiency and longevity, as it helps prevent the buildup of contaminants that can degrade oil quality over time 2.

Purpose of the Tur Oil Drain Tube

The Tur Oil Drain Tube serves a specific role in the operation and maintenance of heavy-duty trucks by enhancing oil drainage efficiency. Its design allows for quicker and more thorough oil removal, which is crucial for maintaining engine health. Efficient oil drainage helps in reducing the risk of engine wear and tear, ensuring that the engine operates within optimal parameters 3.

Key Features

The Tur Oil Drain Tube is characterized by several key features that enhance its functionality and ease of use. It is constructed from durable materials to withstand the harsh conditions within a truck’s engine compartment. Its design facilitates easy installation, minimizing downtime during maintenance. Additionally, the tube is engineered to be compatible with Cummins engines, ensuring a seamless fit and operation 4.

Benefits

Utilizing the Tur Oil Drain Tube offers several advantages. It improves the efficiency of oil drainage, which can lead to reduced maintenance time. The enhanced drainage also contributes to the overall health of the engine by ensuring that old oil, along with any contaminants it may contain, is effectively removed. This can potentially extend the engine’s life by maintaining optimal lubrication conditions 5.

Installation Process

Installing the Tur Oil Drain Tube requires careful attention to detail to ensure proper function and longevity. The process involves securing the tube in place within the engine’s oil drainage system, ensuring that it is correctly aligned and sealed to prevent leaks. Best practices include verifying the tube’s compatibility with the specific engine model and following the manufacturer’s guidelines for installation to avoid common pitfalls such as misalignment or improper sealing 6.

Maintenance Tips

To ensure the Tur Oil Drain Tube operates at peak efficiency, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage at specified intervals and cleaning it as necessary to remove any buildup that could impede oil flow. Proper maintenance not only ensures the tube’s longevity but also contributes to the overall efficiency of the engine’s oil management system 7.

Troubleshooting Common Issues

Common issues associated with the Tur Oil Drain Tube may include leaks or blockages. Leaks can often be traced to improper installation or wear and may require resealing or replacement of the tube. Blockages, on the other hand, can be addressed by cleaning the tube and ensuring that there are no obstructions within the oil drainage path. Regular inspections can help identify these issues early, allowing for timely intervention 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a diverse product range, Cummins is committed to advancing technology in the diesel engine and related technologies market. Their focus on quality, performance, and customer satisfaction has established them as a trusted name in the industry 9.

Tur Oil Drain Tube (Part 3054335) in Cummins Engines

The Tur Oil Drain Tube, identified by the part number 3054335, is a critical component in several Cummins engine models. This part is designed to facilitate the drainage of lubricating oil from the turbocharger, ensuring that the turbocharger operates efficiently and prolonging its lifespan.

V903 Engines

In the V903 engine series, the Tur Oil Drain Tube is integral to the turbocharger system. It is responsible for channeling oil from the turbocharger to the engine’s oil sump, preventing oil accumulation that could lead to turbocharger failure. The design of the V903 engine, which is known for its robust performance and reliability, necessitates a precise and durable oil drain tube to maintain optimal engine operation 10.

Grouping of Engines

The Tur Oil Drain Tube is also compatible with other Cummins engine models that share similar turbocharger designs and oil management systems. These engines benefit from the efficient oil drainage provided by the 3054335 part, ensuring that the turbocharger remains lubricated without excess oil buildup.

The integration of this part in various Cummins engines highlights its versatility and importance in maintaining the health and efficiency of the turbocharger system.

Role of Part 3054335 Tur Oil Drain Tube in Engine Systems

The Part 3054335 Tur Oil Drain Tube is an essential component in the efficient operation of various engine systems. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the oil does not accumulate and potentially cause damage.

Integration with the Oil Pan and Pan

The Tur Oil Drain Tube is strategically positioned to connect the oil pan with the turbocharger. This connection allows for the seamless flow of oil from the turbocharger back into the oil pan. The oil pan, which serves as the reservoir for engine oil, relies on this tube to maintain optimal oil levels and prevent overflow. The pan, often synonymous with the oil pan in engine terminology, benefits from the efficient drainage provided by the Tur Oil Drain Tube, ensuring that the oil pan does not become overfilled, which could lead to oil leaks or reduced engine performance 11.

Interaction with the Oil System

Within the broader oil system of the engine, the Tur Oil Drain Tube plays a significant role in maintaining the lubrication cycle. As oil is circulated through the engine, it passes through various components, including the turbocharger. The turbocharger requires a consistent supply of oil for lubrication and cooling. After performing its function, the oil must be drained back into the system to be recirculated. The Tur Oil Drain Tube ensures this drainage is efficient, maintaining the integrity of the oil system and promoting consistent lubrication across all engine components 12.

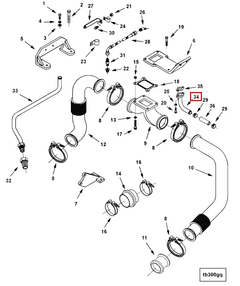

Turbocharger Mounting and Plumbing

The turbocharger mounting system is designed to secure the turbocharger in place while allowing for necessary connections, such as oil and air lines. The Tur Oil Drain Tube is an integral part of the turbocharger plumbing, which includes all the pipes and tubes that facilitate the flow of oil and other fluids to and from the turbocharger. Proper turbocharger plumbing is essential for the turbocharger’s performance and longevity. The Tur Oil Drain Tube ensures that oil draining from the turbocharger is efficiently returned to the oil pan, preventing any buildup that could affect the turbocharger’s operation 13.

Conclusion

In summary, the Part 3054335 Tur Oil Drain Tube is a vital component that ensures the proper functioning of the oil system in conjunction with the oil pan, turbocharger mounting, and turbocharger plumbing. Its role in facilitating the drainage of oil from the turbocharger back into the oil pan is essential for maintaining engine performance and longevity.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4388788.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Berns, K., et al. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4388788.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins official website.

↩ -

Cummins Inc. (n.d.). V903 Engine Series Specifications. Retrieved from Cummins official website.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Turbocharger Plumbing Guidelines. Retrieved from Cummins official website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.