This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

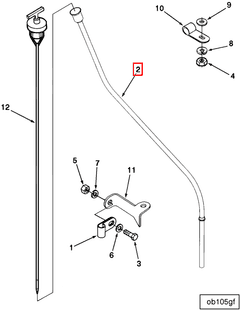

The Cummins 3062603 Oil Gauge Tube is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate the accurate measurement and monitoring of engine oil levels and pressure. This part plays a role in ensuring the engine operates within optimal parameters, thereby contributing to the overall efficiency and longevity of the vehicle 1.

Function and Operation

The Oil Gauge Tube operates within the engine’s lubrication system, where it serves to monitor oil levels and pressure. By providing a pathway for oil to travel from the sump to the gauge, it enables the driver to observe the oil level in real-time. Additionally, the tube is involved in the pressure monitoring system, which helps in assessing the health and performance of the lubrication system. Proper oil levels and pressure are vital for reducing friction, cooling engine components, and ensuring smooth operation 2.

Key Features

The Cummins 3062603 is constructed with specific design and material features to enhance its performance and durability. It is typically made from high-quality materials that can withstand the harsh conditions within an engine environment. The tube’s dimensions are precisely engineered to fit within the engine’s design, ensuring a secure and effective installation. Unique attributes may include corrosion-resistant coatings or reinforced sections to handle high pressure and temperature variations.

Benefits

This Cummins part offers several advantages. It provides accurate oil level readings, which are crucial for maintaining proper lubrication and preventing engine damage. Its reliable performance under various operating conditions ensures that the engine receives consistent lubrication, contributing to overall engine health and longevity. Additionally, the tube’s design and construction contribute to its durability, reducing the need for frequent replacements.

Installation and Maintenance

Proper installation of the Oil Gauge Tube is essential for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and accurate readings. Regular maintenance procedures, such as checking for leaks, ensuring the tube is free from obstructions, and verifying the accuracy of the gauge, are recommended to ensure optimal performance. Identifying and addressing common issues, such as oil leaks or inaccurate readings, can help maintain the tube’s functionality.

Troubleshooting

Common problems associated with Oil Gauge Tubes may include inaccurate oil level readings, leaks, or blockages. Diagnostic procedures for identifying these issues may involve checking the tube for physical damage, ensuring the gauge is functioning correctly, and verifying the oil level within the sump. Recommended solutions for resolving malfunctions may include cleaning or replacing the tube, repairing leaks, or calibrating the gauge to ensure accurate readings.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company offers a wide range of products and services designed to meet the needs of various industries, including transportation, construction, and agriculture.

Role of Part 3062603 Oil Gauge Tube in Engine Systems

The 3062603 is an integral component in the accurate measurement and monitoring of oil levels within an engine system. It works in conjunction with the bayonet fitting to ensure a secure and leak-proof connection, which is essential for maintaining the integrity of the oil level measurement system.

Integration with Oil Level Gauge

The Oil Gauge Tube is directly connected to the Oil Level Gauge, providing a clear and precise reading of the oil level within the engine. This connection allows for real-time monitoring, enabling engineers and mechanics to make informed decisions regarding oil changes and potential issues within the lubrication system.

Functionality in the System

-

Accurate Measurement: The tube facilitates the transfer of oil level data from the engine sump to the gauge, ensuring that the readings are accurate and reliable.

-

System Integrity: By connecting securely with the bayonet fitting, the tube prevents oil leaks, which could otherwise lead to inaccurate readings and potential engine damage.

-

Maintenance Indicator: Regular monitoring via the Oil Gauge Tube helps in identifying when oil levels are low, prompting timely refills and maintaining optimal engine performance.

-

Diagnostic Tool: In case of discrepancies in oil level readings, the tube serves as a diagnostic point, allowing for inspection and troubleshooting of the oil system.

Conclusion

In summary, the 3062603 Oil Gauge Tube plays a significant role in the overall health and maintenance of engine systems by providing accurate and reliable oil level measurements. Its integration with the oil level gauge and its functionality within the system ensure that the engine operates efficiently and remains in optimal condition.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.