This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

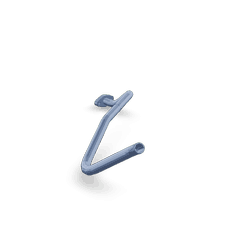

The Tur Oil Drain Tube, identified by part number 3064539, is a component manufactured by Cummins, a leader in diesel engine technology. This part is integral to the maintenance of heavy-duty trucks, specifically within the lubrication system. Its role is to facilitate the drainage of oil from the engine, ensuring that the lubrication system operates efficiently and effectively 1.

Function and Operation

The Tur Oil Drain Tube operates as a conduit within the truck’s engine for the oil drainage process. When it is time to change the oil, the tube allows for the controlled and efficient flow of used oil out of the engine. This process is vital for maintaining the engine’s lubrication system, as it ensures that old, potentially contaminated oil is removed and replaced with fresh oil. The tube’s design and placement within the engine contribute to a streamlined oil change procedure, minimizing the risk of spills and ensuring that the drainage process is both quick and clean 2.

Key Features

The Tur Oil Drain Tube is constructed from high-quality materials, designed to withstand the harsh conditions within a heavy-duty truck engine. Its design includes features that enhance its performance and durability, such as a robust connection mechanism that ensures a secure fit within the engine’s lubrication system. The tube is also engineered to facilitate easy access for oil changes, reducing the time and effort required for maintenance 3.

Benefits of Using the Tur Oil Drain Tube

Incorporating the Tur Oil Drain Tube into a truck’s lubrication system offers several advantages. It contributes to improved engine lubrication by ensuring that old oil is efficiently drained and replaced. This process helps maintain optimal engine performance and can lead to reduced maintenance intervals, as the engine operates more smoothly with fresh lubrication. Additionally, the tube’s design and material composition enhance the overall durability and reliability of the lubrication system 4.

Installation and Compatibility

For the Tur Oil Drain Tube to function correctly, it must be installed according to manufacturer guidelines. Compatibility with various Cummins engines is a key consideration, ensuring that the tube integrates seamlessly into the truck’s lubrication system. Specific requirements for installation may include ensuring a proper seal to prevent leaks and verifying that the tube is correctly aligned with the engine’s drainage system 5.

Maintenance and Troubleshooting

Regular maintenance of the Tur Oil Drain Tube is important to ensure its optimal functioning. This includes checking for signs of wear or damage and ensuring that all connections are secure. Common issues that may arise include leaks or blockages, which can often be resolved by inspecting the tube and connections, and making any necessary adjustments or replacements 6.

Safety Considerations

When working with the Tur Oil Drain Tube, it is important to observe safety guidelines. This includes handling hot oil with care to avoid burns and ensuring that the tube is properly sealed to prevent leaks. Following manufacturer instructions for installation and maintenance can help mitigate risks and ensure a safe working environment 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the diesel engine market, offering products that are designed to meet the demanding requirements of heavy-duty applications 8.

Conclusion

The Tur Oil Drain Tube, part number 3064539, is a critical component in the maintenance and operational efficiency of heavy-duty truck engines. Its role in facilitating the drainage of used oil ensures that the lubrication system operates efficiently, contributing to the overall performance and longevity of the engine. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5579829.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5579829.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.