This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

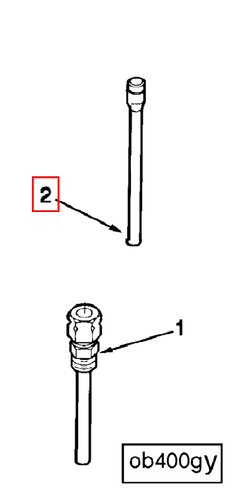

The Cummins 3064818 Oil Gauge Tube is a specialized component designed for use in heavy-duty trucks. It plays a significant role within the engine’s lubrication system, contributing to the overall performance and longevity of the engine. Understanding its function and importance can aid in maintaining the truck’s engine efficiently.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is an integral part of the engine lubrication system, facilitating the monitoring of oil levels and pressure within the engine. It connects to the oil gauge, providing a visual indication of oil levels and pressure, which are essential for maintaining optimal engine performance. Proper lubrication is necessary to reduce friction between moving parts, cool the engine, and remove contaminants 1.

Purpose of the Cummins 3064818 Oil Gauge Tube

This Cummins part assists in the monitoring of oil levels and pressure, ensuring that the engine receives the appropriate amount of lubrication. This is vital for its efficient operation and longevity. By providing accurate readings, it helps prevent engine damage due to insufficient lubrication.

Key Features

The Cummins 3064818 is characterized by its robust design and the materials used in its construction, which contribute to its performance and durability. It is engineered to withstand the harsh conditions within a truck’s engine compartment, ensuring reliable operation over time. Its design may include features that enhance its compatibility with specific engine models and its resistance to wear and corrosion.

Benefits of Using the Cummins 3064818 Oil Gauge Tube

Incorporating this part into a truck’s engine system offers several advantages. It provides improved accuracy in oil level readings, which is important for maintaining the engine’s lubrication system. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, its design may contribute to easier installation and integration into the engine system.

Installation and Integration

Proper installation of the Cummins 3064818 into a truck’s engine system involves following manufacturer guidelines to ensure it is correctly positioned and securely fastened. This may include preparations such as cleaning the installation area and ensuring compatibility with the engine’s existing components. Careful integration is important to maintain the integrity of the lubrication system and ensure accurate oil level readings.

Troubleshooting Common Issues

Common problems associated with oil gauge tubes can include leaks, inaccurate readings, or blockages. Addressing these issues may involve inspecting the tube for damage, ensuring it is properly installed, and cleaning or replacing it if necessary. Regular maintenance and inspections can help identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3064818, routine maintenance practices are recommended. This includes regular inspections for signs of wear or damage, cleaning the tube and its connections to prevent blockages, and following the manufacturer’s guidelines for replacement schedules. Proper maintenance contributes to the efficient operation of the engine’s lubrication system.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its high-quality components and commitment to innovation. With a history of producing reliable and efficient engine parts, Cummins has built a reputation for excellence. Their components, including the 3064818, are designed with precision and durability in mind, reflecting the company’s dedication to quality and performance.

Compatibility of Cummins Oil Gauge Tube Part 3064818

The Cummins Oil Gauge Tube part number 3064818 is designed to fit a variety of engines, ensuring accurate oil pressure readings and maintaining engine health. Here is a detailed look at its compatibility with specific engine models:

- K19 Series: The part 3064818 is compatible with the K19 engine series, ensuring precise measurements crucial for the engine’s operational integrity.

- KTA19GC CM558: For the KTA19GC CM558 engine, the oil gauge tube part 3064818 is engineered to fit seamlessly, providing reliable oil pressure readings.

- QSK19 CM2350 K114 and QSK19 CM2350 K144G: Both engines are compatible with the Cummins Oil Gauge Tube part 3064818, ensuring accurate oil pressure readings vital for the engine’s operational efficiency and safety.

- QSK19 CM500 and QSK19 CM850 MCRS: The part 3064818 is designed to fit these engines, ensuring precise oil pressure readings critical for the engine’s performance and maintenance.

- QSK19G: Lastly, the QSK19G engine is also compatible with the Cummins Oil Gauge Tube part 3064818, ensuring accurate oil pressure readings essential for the engine’s operational efficiency and safety.

This compatibility across various engine models highlights the versatility and reliability of the Cummins Oil Gauge Tube part 3064818, ensuring that it meets the needs of different engine configurations.

Role of Part 3064818 Oil Gauge Tube in Engine Systems

The Part 3064818 Oil Gauge Tube is an integral component in the oil management system of an engine. It works in conjunction with several key components to ensure the engine operates efficiently and safely.

Integration with the Dipstick Tube

The Oil Gauge Tube interfaces directly with the dipstick tube. This connection allows for the accurate measurement of oil levels within the engine. The dipstick, when inserted into the tube, provides a visual and physical means to check the oil level, ensuring it remains within the optimal range for engine performance and longevity.

Interaction with the Engine Mounting

While the Oil Gauge Tube itself does not directly interact with the engine mounting, its proper installation and maintenance are essential for the overall stability and alignment of engine components. A well-maintained oil gauge tube ensures that oil levels are consistently monitored, which indirectly supports the structural integrity of the engine mounting by preventing oil-related issues that could lead to engine instability.

Functionality with the Gauge

The Oil Gauge Tube is directly connected to the oil level gauge. This connection enables the gauge to provide real-time readings of the oil level. The tube acts as a conduit, allowing the gauge to accurately reflect the current state of the oil within the engine. This real-time data is vital for making informed decisions regarding oil changes and maintenance schedules.

Ensuring Accurate Oil Level Readings

Accurate oil level readings are paramount for engine health. The Oil Gauge Tube plays a significant role in this by providing a clear and unobstructed path for the dipstick and ensuring that the gauge receives precise information. This accuracy helps in preventing both overfilling and underfilling of oil, which can lead to severe engine damage.

Conclusion

In summary, the Part 3064818 Oil Gauge Tube is a key component in the engine’s oil management system, working seamlessly with the dipstick tube, engine mounting, and oil level gauge to ensure the engine operates within safe parameters. Its robust design, compatibility with various engine models, and role in providing accurate oil level readings make it a vital part of maintaining engine efficiency and longevity.

-

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.