This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3067227 Oil Gauge Tube is a component designed for use in heavy-duty trucks. It serves a significant role in the engine’s lubrication system by facilitating the accurate measurement of oil levels. This ensures that the engine operates within optimal parameters, contributing to its longevity and performance 1.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is a part of the engine lubrication system that allows for the monitoring of oil levels within the engine. It works by providing a pathway for oil to travel from the oil pan to the oil gauge, where the level can be observed. This monitoring is vital for maintaining proper lubrication, which is necessary for reducing friction and wear on engine components 2.

Purpose of the Cummins 3067227 Oil Gauge Tube

The Cummins 3067227 Oil Gauge Tube plays a role in the operation of a truck by ensuring accurate oil level measurement. This is achieved through its design, which allows for a consistent and reliable flow of oil to the gauge. Accurate oil level readings are important for maintaining engine performance and preventing damage due to insufficient lubrication.

Key Features

The Cummins 3067227 Oil Gauge Tube is characterized by its robust design and the materials used in its construction. It is made from high-quality materials that offer resistance to corrosion and wear, ensuring durability under the demanding conditions of heavy-duty truck operation. Its design also includes features that enhance the accuracy of oil level readings.

Benefits of Using the Cummins 3067227 Oil Gauge Tube

Using the Cummins 3067227 Oil Gauge Tube offers several advantages. It provides improved accuracy in oil level readings, which is important for maintaining optimal engine lubrication. This, in turn, enhances engine protection by ensuring that all moving parts are properly lubricated, reducing the risk of wear and damage. Additionally, its reliability in various operating conditions makes it a valuable component for heavy-duty applications.

Installation and Compatibility

Proper installation of the Cummins 3067227 Oil Gauge Tube is important for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to ensure compatibility with Cummins engines. This includes adhering to any specific requirements for sealing and securing the tube within the engine system.

Maintenance and Troubleshooting

Maintaining the Cummins 3067227 Oil Gauge Tube involves regular inspection and cleaning to ensure its continued accuracy and reliability. This includes checking for any signs of wear or damage and cleaning the tube to remove any debris that may affect its performance. Troubleshooting common issues, such as inaccurate readings or leaks, may involve inspecting the tube for blockages or damage and addressing these issues as necessary.

Common Issues and Solutions

Common problems associated with oil gauge tubes include inaccurate readings and leaks. Inaccurate readings may be due to blockages within the tube or issues with the gauge itself. Leaks can occur due to wear or damage to the tube or its seals. Addressing these issues may involve cleaning the tube, replacing damaged components, or ensuring proper installation.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its diesel engines and related components. The company has a history of innovation and commitment to quality, which is reflected in its product offerings. Cummins engines and components, including the 3067227 Oil Gauge Tube, are designed with a focus on durability, performance, and reliability, making them a popular choice for heavy-duty applications.

Role of Part 3067227 Oil Gauge Tube in Engine Systems

The part 3067227 Oil Gauge Tube is an integral component in the arrangement of an engine’s oil system. It facilitates the accurate measurement and display of the oil level within the engine, ensuring optimal performance and longevity.

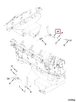

Integration with Oil Fill and Gauge Components

The Oil Gauge Tube is strategically positioned to connect the oil fill area with the oil gauge. This connection allows for the precise transmission of oil level data from the engine’s sump to the gauge. The tube’s design ensures that the oil level reading is consistent and reliable, providing engineers and mechanics with accurate information for maintenance and diagnostic purposes.

Interaction with Oil Level and Location Systems

In conjunction with the oil level sensor, the Oil Gauge Tube plays a significant role in determining the exact quantity of oil present in the engine. This is particularly important during oil changes or top-ups, as it allows for the correct amount of oil to be added, maintaining the engine’s lubrication system efficiency.

The location of the Oil Gauge Tube within the engine is carefully considered to avoid interference with other components while ensuring a direct and unobstructed path for oil level measurement. This precise placement is essential for the accurate functioning of the oil gauge.

Contribution to Oil Gauge Accuracy

The Oil Gauge Tube’s hardware is designed to withstand the pressures and temperatures within the engine, ensuring that the oil gauge provides a consistent and accurate reading. This reliability is vital for the ongoing monitoring of the engine’s health, as it allows for the early detection of potential issues such as oil leaks or consumption.

Conclusion

In summary, the Cummins 3067227 Oil Gauge Tube is a key element in the engine’s oil management system, working in harmony with the oil fill, gauge, oil level sensor, and location systems to provide accurate and reliable oil level readings. Its robust design, compatibility with Cummins engines, and the benefits it offers in terms of engine protection and performance make it a valuable component for heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.