This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

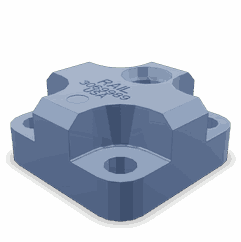

The Oil Control Valve Cover, identified by Part #3069989, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This part is integral to the operation of heavy-duty truck engines, ensuring optimal performance and efficiency. Cummins, known for its robust and reliable engine solutions, has designed this valve cover to meet the demanding requirements of heavy-duty applications 1.

Function and Operation

The Oil Control Valve Cover operates within the engine system by managing the flow and pressure of oil. It is designed to regulate oil distribution to various engine components, ensuring that each part receives the necessary lubrication for smooth operation. This regulation helps maintain consistent oil pressure, which is vital for the engine’s longevity and performance 2.

Purpose of the Oil Control Valve Cover

The Oil Control Valve Cover plays a specific role in the operation of a truck by contributing to engine performance and efficiency. By ensuring proper oil flow and pressure, it helps reduce friction between moving parts, which can lead to wear and tear. This, in turn, supports the engine’s overall efficiency and reliability, allowing for smoother operation under various driving conditions 3.

Key Features

The primary features of the Oil Control Valve Cover include its material composition, which is designed to withstand the high temperatures and pressures within the engine compartment. Its design elements are tailored to provide a secure fit and effective sealing, preventing oil leaks. Additionally, unique characteristics such as integrated sensors or gauges may enhance its functionality, providing real-time data on oil conditions.

Benefits

The advantages provided by the Oil Control Valve Cover include improved engine reliability, enhanced performance, and potential cost savings for fleet operators. By ensuring optimal oil flow and pressure, it contributes to the engine’s longevity, reducing the need for frequent repairs or replacements. This reliability can lead to lower maintenance costs and improved operational efficiency.

Troubleshooting and Maintenance

Common issues that may arise with the Oil Control Valve Cover include oil leaks or malfunctions in oil pressure regulation. Recommended maintenance practices involve regular inspections for signs of wear or damage, ensuring that all connections are secure, and replacing the cover if any issues are detected. Troubleshooting steps may include checking for blockages in the oil passages or verifying the integrity of the seals.

Integration with Engine Systems

The Oil Control Valve Cover interacts with other engine components and systems, playing a role in the overall engine operation. It works in conjunction with the oil pump, filters, and various engine parts to ensure that oil is distributed efficiently throughout the engine. This integration is crucial for maintaining the engine’s performance and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of engine solutions designed to meet the needs of heavy-duty applications, underscoring the quality and reliability of the Oil Control Valve Cover.

Application in Heavy-Duty Trucks

The Oil Control Valve Cover is utilized in heavy-duty trucks, where it is commonly installed in various models to ensure optimal engine performance. Its application in these vehicles highlights its importance in supporting the demanding requirements of heavy-duty operations, contributing to the overall efficiency and reliability of the truck’s engine system.

Technological Advancements

The design and manufacturing of the Oil Control Valve Cover incorporate technological innovations that enhance its performance and durability. These advancements may include the use of advanced materials for improved heat resistance, precision engineering for a perfect fit, and integration of smart technologies for real-time monitoring of oil conditions.

Environmental Impact

The Oil Control Valve Cover contributes to reducing environmental impact by supporting improvements in fuel efficiency and emissions reduction. By ensuring optimal oil flow and pressure, it helps the engine operate more efficiently, which can lead to lower fuel consumption and reduced emissions. This aligns with the industry’s move towards more sustainable and environmentally friendly solutions.

Customer Feedback and Reviews

Customer experiences and reviews regarding the Oil Control Valve Cover provide insights into its real-world performance and reliability. Feedback often highlights its effectiveness in maintaining engine performance, durability under demanding conditions, and the peace of mind it offers to fleet operators in terms of reduced maintenance needs.

Future Developments

Potential future enhancements or developments for the Oil Control Valve Cover may include further integration of smart technologies for real-time monitoring and diagnostics, the use of even more durable materials to withstand extreme conditions, and designs that further improve fuel efficiency and reduce emissions. These developments will likely be influenced by current trends in engine technology and Cummins’ ongoing innovation efforts.

Compatibility

This Cummins part is designed to fit a range of Cummins engines, ensuring optimal performance and reliability across various applications. It is engineered to work seamlessly with the following engines:

- 6B5.9

- K19

- K38

- K50

- M11 CELECT PLUS

- M11 MECHANICAL

- N14 MECHANICAL

- NH/NT 855

This oil control valve cover is a critical component in managing the oil flow within the engine, ensuring that the lubrication system operates efficiently. It is essential for maintaining the health of the engine by preventing oil contamination and ensuring that the oil reaches all necessary components.

Role in Engine Systems

This part is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency.

Integration with Key Components

-

Cylinder Head Mounting and Camshaft and Gear: The Oil Control Valve Cover interfaces directly with the cylinder head mounting and the camshaft and gear. It facilitates the regulation of oil flow to these components, which is essential for maintaining proper lubrication and reducing wear.

-

Cam Follower Housing: By controlling the oil supply to the cam follower housing, the cover helps in minimizing friction and enhancing the durability of the cam followers.

-

Timing Control and Timing Ctl: The cover works in conjunction with the timing control system to ensure that oil is delivered at the right moments, which is vital for the precise operation of the timing mechanisms.

-

Injector and Injector Plumbing: It plays a role in the efficient operation of the injector system by ensuring that the injectors receive a consistent oil supply, which is crucial for their performance and longevity.

-

Oil Control Valve and Oil Control Top Level Assembly Valve: The cover is a part of the oil control system, working with the oil control valve and the top-level assembly valve to manage oil pressure and flow throughout the engine.

-

Step Control Valve and Step Oil Control Top Level Assembly Valve: It assists in the step control valve’s function by providing regulated oil pressure, which is necessary for the valve’s operation in managing engine performance under varying conditions.

-

Viscosity Sensor: The cover contributes to the accuracy of the viscosity sensor by ensuring a stable oil environment, which allows the sensor to provide reliable data for engine management.

-

EBM: Performance Parts and EBM: Device: When integrated with EBM performance parts and devices, the cover enhances the overall performance of these components by providing them with optimal oil conditions.

-

Dual STC K38 and Dual STC K50 Kits: In combination with these kits, the cover aids in fine-tuning the engine’s oil management system, which is essential for the kits’ intended performance enhancements.

-

Step White Smoke Kit: The cover is also involved in the operation of the step white smoke kit by ensuring that the oil system is functioning correctly, which helps in reducing unwanted emissions.

-

Aftercooler: Although indirectly, the cover’s role in maintaining the engine’s oil system efficiency can contribute to the aftercooler’s effectiveness by ensuring that the engine operates within its optimal temperature range.

Conclusion

In summary, the Oil Control Valve Cover (3069989) is a key player in the engine’s oil management system, interacting with a variety of components to ensure that the engine operates smoothly, efficiently, and with longevity. Its design, compatibility, and integration with engine systems highlight its importance in maintaining the performance and reliability of heavy-duty truck engines.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.