3070167

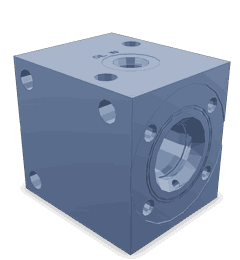

Oil Control Valve Body

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Oil Control Valve Body (Part #3070167) manufactured by Cummins is a component designed to enhance the performance and efficiency of heavy-duty truck engines. It is integral to the engine management system, ensuring that oil is distributed effectively to various engine components. This part contributes to the overall functionality and reliability of the engine, playing a significant role in maintaining optimal engine operation 1.

Function and Operation

The Oil Control Valve Body operates by regulating the flow of oil to different engine components. It interacts with the engine control unit (ECU) to adjust oil flow based on engine conditions and requirements. This regulation ensures that engine components receive the necessary lubrication and cooling, which is vital for maintaining engine performance and longevity. The valve body employs precise mechanisms to control oil pressure and flow, adapting to the engine’s needs in real-time 2.

Purpose of the Oil Control Valve Body in Truck Operation

In heavy-duty trucks, the Oil Control Valve Body plays a specific role in enhancing engine efficiency, performance, and longevity. By ensuring that oil is distributed effectively, it helps maintain engine components in optimal condition, reducing wear and tear. This contributes to the overall functionality of the engine system, allowing the truck to operate more efficiently and reliably under various conditions 3.

Key Features

The Oil Control Valve Body is characterized by its robust design and the use of high-quality materials, ensuring durability and performance. It is engineered to integrate seamlessly with other engine components, enhancing the overall efficiency of the engine system. Unique features such as precise oil flow control and compatibility with advanced engine management systems further enhance its performance and reliability.

Benefits

The advantages provided by the Oil Control Valve Body include improved engine performance, enhanced fuel efficiency, reduced emissions, and increased reliability. These benefits contribute to the overall operation and maintenance of heavy-duty trucks, making them more efficient and environmentally friendly. The valve body’s role in maintaining optimal engine conditions also reduces the need for frequent maintenance, enhancing the truck’s operational reliability.

Installation and Integration

Proper installation and integration of the Oil Control Valve Body within the engine system are crucial for ensuring compatibility and optimal performance. Installation guidelines include prerequisites such as ensuring the engine is clean and free of debris, following the manufacturer’s instructions for placement and connection, and verifying that all connections are secure and properly sealed. Careful attention to these steps ensures that the valve body functions effectively within the engine system.

Troubleshooting and Maintenance

For troubleshooting common issues related to the Oil Control Valve Body, diagnostic procedures may include checking for leaks, blockages, or electrical issues. Potential causes of malfunctions can be identified through systematic inspection and testing. Recommended maintenance practices include regular inspection for signs of wear or damage, ensuring connections are secure, and following the manufacturer’s guidelines for servicing and replacement. These practices help ensure the longevity and reliable operation of the valve body.

Common Failure Modes

Typical failure modes associated with the Oil Control Valve Body include leaks, blockages, or electrical issues. Symptoms that may indicate a failing valve body include changes in engine performance, unusual noises, or warning lights on the dashboard. Diagnosis and repair steps may involve inspecting the valve body for physical damage, checking electrical connections, and replacing the component if necessary. Addressing these issues promptly helps maintain engine performance and reliability.

Impact on Engine Performance

The performance of the Oil Control Valve Body directly affects engine operation, including changes in oil pressure, engine responsiveness, and overall efficiency. A malfunctioning valve body can lead to inadequate oil distribution, resulting in increased wear on engine components, reduced performance, and potential engine damage. Maintaining the valve body in optimal condition is therefore important for ensuring the truck’s performance and longevity.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its commitment to innovation, quality, and customer satisfaction. The company offers a wide range of products, including engine components like the Oil Control Valve Body. Cummins’ dedication to designing and manufacturing high-quality parts ensures that their products meet the demanding requirements of heavy-duty applications, contributing to the reliability and performance of engines in various industries.

Cummins Oil Control Valve Body (Part 3070167) Compatibility

The Cummins Oil Control Valve Body, part number 3070167, is a critical component in the engine’s lubrication system. This part is designed to manage the flow of oil within the engine, ensuring optimal lubrication and performance. It is compatible with several Cummins engine models, including:

- K19

- M11 CELECT PLUS

- M11 MECHANICAL

- N14 MECHANICAL

- NH/NT 855

For the K19 engine, the Oil Control Valve Body plays a pivotal role in maintaining the intricate balance of oil pressure and flow, which is essential for the engine’s high-performance capabilities.

In the M11 CELECT PLUS and M11 MECHANICAL engines, this part is integral to the engine’s electronic control system. It ensures that the oil pressure is regulated according to the engine’s operational demands, enhancing both efficiency and longevity.

The N14 MECHANICAL engine also benefits from the precise control offered by the Oil Control Valve Body. This part helps maintain consistent oil pressure, which is crucial for the engine’s durability and performance under heavy-duty conditions.

Lastly, in the NH/NT 855 engines, the Oil Control Valve Body is designed to handle the specific requirements of these models. It ensures that the oil flow is optimized for the engine’s unique design, contributing to its overall reliability and efficiency.

Understanding the Role of Part 3070167 Oil Control Valve Body in Engine Systems

Part 3070167, the Oil Control Valve Body, is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency. Its role is multifaceted, interacting with several key components to regulate oil flow and pressure, which in turn affects engine operation and performance.

Interaction with the Cylinder Head and Camshaft

The Oil Control Valve Body works in conjunction with the cylinder head and camshaft to manage oil distribution. By controlling the oil flow to the camshaft, it influences the operation of the valve timing system. This interaction is vital for maintaining precise valve timing, which is essential for engine efficiency and power output.

Coordination with the Timing Control System

In engines equipped with variable valve timing (VVT) systems, the Oil Control Valve Body is a key player. It receives signals from the timing control system and adjusts the oil pressure sent to the camshaft phasers. This adjustment allows for dynamic changes in valve timing, optimizing engine performance across different operating conditions.

Integration with the Hydro-Mechanical Step System

For engines utilizing a hydro-mechanical step system, the Oil Control Valve Body’s role becomes even more significant. It facilitates the step changes in valve timing by precisely controlling oil flow to the phasers. This capability is essential for engines that require rapid adjustments in valve timing to meet performance demands or emissions standards.

Support for the Injector and Aftercooler Systems

Although not directly connected, the efficient operation of the Oil Control Valve Body indirectly supports the injector and aftercooler systems. By ensuring the engine runs smoothly and efficiently, it reduces the load on these systems, allowing them to operate within their optimal parameters.

Contribution to Overall Engine Performance

The Oil Control Valve Body’s ability to fine-tune oil flow and pressure across various engine components contributes to the overall performance of the engine. It helps in reducing friction, improving fuel efficiency, and enhancing power output. Moreover, by ensuring consistent oil pressure, it aids in the longevity of engine parts, including the connecting rod and piston, and the cylinder head mounting.

Role in EBM: Performance Parts and Devices

In the context of EBM (Engine Boost Module) performance parts and devices, the Oil Control Valve Body plays a supportive yet significant role. It ensures that the advanced features of these performance enhancements are fully realized by providing the necessary oil control. This integration is key to unlocking the full potential of performance-oriented engine modifications.

Conclusion

The Oil Control Valve Body, part 3070167, is a sophisticated component that enhances engine performance by precisely managing oil flow and pressure. Its interactions with various engine systems underscore its importance in modern engine design and operation. Ensuring the proper function and maintenance of this part is crucial for the optimal performance and longevity of heavy-duty truck engines.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.