This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

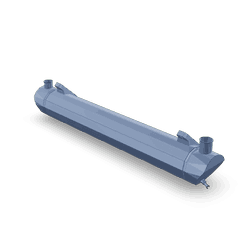

The Cummins 3073210 Oil Cooler is a component designed for use in commercial trucks. It serves to regulate the temperature of the engine oil, ensuring that it remains within optimal operating parameters. This regulation is vital for maintaining engine performance and longevity, particularly in heavy-duty applications where the engine is subjected to prolonged periods of high stress and heat 3.

Basic Concepts of Oil Coolers

An oil cooler is a device that helps manage the temperature of the engine oil by transferring excess heat away from the oil and dissipating it into the surrounding environment. It operates on the principle of heat exchange, where the oil passes through a series of tubes or fins that are exposed to cooler air, allowing the heat to be released. This process ensures that the oil remains at a temperature that promotes efficient lubrication and reduces the risk of thermal degradation 2.

Purpose of the Cummins 3073210 Oil Cooler

This Cummins part plays a specific role in maintaining optimal engine performance and longevity by aiding in the regulation of oil temperature. By keeping the oil within the desired temperature range, it helps to ensure that the engine operates efficiently and that the oil retains its lubricating properties. This is particularly important in commercial trucks, where the engine is often under significant load and the oil is subjected to high temperatures 3.

Key Features

The Cummins 3073210 Oil Cooler is characterized by several key features that enhance its performance. Its design incorporates a series of tubes or fins that maximize the surface area for heat exchange, allowing for efficient cooling. The materials used in its construction are chosen for their durability and resistance to corrosion, ensuring long-term reliability. Additionally, the cooler may feature unique characteristics such as a compact design for easy integration into the engine system or advanced coatings to further protect against wear and corrosion 1.

Benefits of Using the Cummins 3073210 Oil Cooler

The use of this part offers several advantages. It contributes to improved engine efficiency by ensuring that the oil remains at an optimal temperature, which in turn helps to reduce friction and wear on engine components. This can lead to extended oil life, as the oil is less likely to break down under high temperatures. Furthermore, the cooler enhances overall truck performance by supporting consistent engine operation, which is crucial for the reliability and productivity of commercial vehicles 3.

Installation and Integration

Proper installation and integration of the Cummins 3073210 Oil Cooler into a truck’s engine system are important for ensuring its effective operation. This process may involve preparing the mounting location, connecting the oil lines, and ensuring that the cooler is securely fastened. It is also important to consider the orientation of the cooler to maximize airflow and cooling efficiency. Following the manufacturer’s guidelines for installation will help to ensure that the cooler functions as intended 1.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the optimal functioning of the Cummins 3073210 Oil Cooler. This may include regular inspections for signs of wear or damage, cleaning the cooler to remove any debris that could impede airflow, and checking the connections for leaks. Troubleshooting common issues, such as reduced cooling efficiency or oil leaks, may involve inspecting the cooler for blockages, ensuring that the oil lines are properly connected, and verifying that the cooler is receiving adequate airflow 3.

Performance and Efficiency

The Cummins 3073210 Oil Cooler contributes to the overall performance and efficiency of a truck’s engine by helping to maintain optimal oil temperature. This can result in measurable improvements such as reduced oil consumption, lower operating temperatures, and enhanced engine reliability. By supporting efficient lubrication and reducing the risk of thermal degradation, the cooler plays a role in promoting the long-term health and performance of the engine 3.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a reputation for producing high-quality automotive components. The company has a long history of innovation and commitment to excellence in the industry. Cummins is known for its dedication to developing reliable and efficient solutions for a wide range of applications, including commercial trucks. The Cummins 3073210 Oil Cooler is a testament to the company’s expertise in designing components that contribute to the performance and durability of engines 1.

Compatibility with Engine Models

The Cummins Oil Cooler part number 3073210 is designed to be compatible with a range of engine models, ensuring efficient oil cooling and optimal engine performance. This oil cooler is engineered to fit seamlessly with the following Cummins engine models:

- V903

- VTA903 CM2250 V105

These engines, while distinct in their specifications and applications, share a commonality in their requirement for effective oil cooling systems. The 3073210 oil cooler is specifically tailored to meet the cooling needs of these engines, providing a reliable solution for maintaining oil temperature within the optimal range 1.

Role of Part 3073210 Oil Cooler in Engine Systems

The part 3073210 Oil Cooler is an essential component in maintaining the optimal operating temperature of engine oil within various engine systems. By facilitating the heat exchange process, this oil cooler ensures that the engine oil remains within the desired temperature range, which is vital for the efficient functioning of the engine 2.

Integration with Engine Oil System

In the engine oil system, the oil cooler works in conjunction with the oil pump and filter to regulate the temperature of the circulating oil. As the engine operates, the oil absorbs heat from various engine components. The oil cooler dissipates this heat, preventing the oil from overheating, which could lead to a breakdown of its lubricating properties and potential engine damage 3.

Interaction with Lubricating Oil

The lubricating oil, which is critical for reducing friction between moving parts, relies on the oil cooler to maintain its viscosity and effectiveness. When the oil is too hot, its viscosity decreases, which can lead to inadequate lubrication and increased wear on engine components. The oil cooler helps to maintain the oil at an optimal temperature, ensuring consistent lubrication and protection for the engine 3.

Relationship with Oil Filter

The oil filter plays a role in removing contaminants from the engine oil, which is necessary for maintaining the oil’s cleanliness and effectiveness. The oil cooler supports this process by ensuring that the oil remains at a temperature where it can effectively carry contaminants to the filter. Additionally, cooler oil is less likely to break down and form sludge, which can clog the filter and reduce its efficiency 3.

Overall System Efficiency

By integrating the oil cooler into the engine system, the overall efficiency and longevity of the engine are enhanced. The cooler ensures that the engine oil maintains its lubricating properties, reduces the risk of overheating, and supports the filter in keeping the oil clean. This results in smoother engine operation, reduced wear on components, and extended engine life 3.

Conclusion

The Cummins 3073210 Oil Cooler is a critical component in the maintenance of engine oil temperature, ensuring optimal engine performance and longevity. Its design and features contribute to efficient heat exchange, durability, and compatibility with various engine models. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing its benefits and ensuring the reliability and efficiency of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.