This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3074003 Oil Control Valve is a component designed for use in commercial trucks, specifically within Cummins engines. This valve is integral to the operation of these engines, facilitating the management of oil flow to optimize engine performance and efficiency. Its role is significant in ensuring that the engine operates smoothly under various conditions, contributing to the overall reliability and durability of the truck.

Basic Concepts of Oil Control Valves

An Oil Control Valve (OCV) is a device that regulates the flow of oil within an engine. It operates by adjusting the timing of the valve train, which in turn affects the engine’s performance and efficiency. The OCV plays a role in managing oil flow to different parts of the engine, ensuring that each component receives the necessary lubrication and cooling. This regulation is crucial for maintaining engine health and performance, as it helps to prevent wear and tear on engine parts 1.

Purpose of the 3074003 Oil Control Valve

The Cummins 3074003 Oil Control Valve is specifically designed to work within variable valve timing (VVT) systems. Its purpose is to adjust the timing of the valve train by controlling the flow of oil to the camshaft phaser. This adjustment allows the engine to operate more efficiently across a range of speeds and loads, enhancing both performance and fuel economy. By fine-tuning the valve timing, the 3074003 OCV contributes to smoother engine operation and reduced emissions 2.

Key Features

The Cummins 3074003 Oil Control Valve is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the demanding conditions of commercial truck engines, ensuring long-term reliability. The valve features precise machining and durable construction, which are critical for its accurate operation within the VVT system. Additionally, its design allows for efficient oil flow management, contributing to the overall performance of the engine 3.

Benefits

The integration of the Cummins 3074003 Oil Control Valve into an engine system offers several benefits. It contributes to improved engine efficiency by optimizing valve timing, which can lead to better fuel economy. Additionally, the valve helps in reducing emissions by ensuring that the engine operates at peak efficiency. Its durable construction and precise operation also enhance the longevity and reliability of the engine, providing value to truck operators.

Installation and Integration

Installing the Cummins 3074003 Oil Control Valve requires careful attention to ensure it is properly integrated into the engine system. It is important to follow manufacturer guidelines for installation, including any specific torque specifications and alignment requirements. Proper installation is key to ensuring the valve functions correctly within the VVT system, contributing to optimal engine performance.

Troubleshooting and Maintenance

Common issues with the Cummins 3074003 Oil Control Valve may include oil leaks, erratic engine performance, or failure to adjust valve timing correctly. Diagnostic steps may involve checking for proper oil pressure, inspecting the valve for physical damage, and ensuring it is correctly installed. Regular maintenance, including checking for leaks and ensuring the valve operates smoothly, can help prevent issues and ensure long-term performance.

Performance Impact

The Cummins 3074003 Oil Control Valve has a noticeable impact on engine performance. By optimizing valve timing, it contributes to smoother engine operation, improved fuel efficiency, and reduced emissions. Its role in the VVT system allows the engine to adapt to different operating conditions, enhancing overall truck performance and efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s commitment to advancing technology and improving engine performance is evident in its product offerings, including the Cummins 3074003 Oil Control Valve.

Role of Part 3074003 Oil Control Valve in Engine Systems

The 3074003 Oil Control Valve is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency.

Integration with Key Components

-

Camshaft and Gear: The OCV works in tandem with the camshaft and gear system. It modulates oil flow to the Variable Valve Timing (VVT) mechanism, allowing precise adjustments to camshaft timing. This enhances engine responsiveness and fuel efficiency.

-

Oil Manifold: The OCV is typically connected to the oil manifold, which distributes oil to various engine components. The valve regulates the oil pressure and flow rate directed to the camshaft phasers, ensuring they operate within specified parameters.

-

Viscosity Sensor: In conjunction with the viscosity sensor, the OCV adapts oil flow based on the oil’s viscosity. This ensures that the VVT system receives the appropriate oil pressure regardless of temperature variations, maintaining consistent valve timing.

-

Rocker Housing: The OCV is often housed within the rocker housing, where it can efficiently manage oil distribution to the overhead camshaft(s). This setup allows for better control over valve operation and timing.

-

Hydro-Mechanical Step: In engines equipped with hydro-mechanical step systems, the OCV plays a role in transitioning between different camshaft profiles. By controlling oil flow, it enables smooth and rapid changes in camshaft position, optimizing engine performance across various operating conditions.

-

Check Valve: The OCV often incorporates or works alongside check valves to prevent backflow of oil, ensuring that pressure is maintained within the VVT system. This is essential for the reliable operation of camshaft phasers.

-

Aftercooler Core and Plumbing: In turbocharged engines, the OCV’s efficient management of oil flow can indirectly influence the performance of the aftercooler core and its associated plumbing. Proper oil control ensures that the turbocharger and its components operate within their optimal temperature and pressure ranges, contributing to overall engine performance and durability.

-

Injector: Although the OCV does not directly interact with fuel injectors, its role in optimizing valve timing can indirectly affect fuel delivery. Improved valve timing leads to better air-fuel mixture control, enhancing combustion efficiency and overall engine performance.

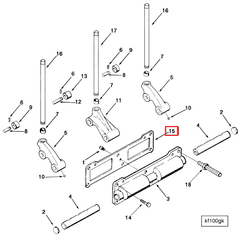

Performance Parts

In high-performance applications, the OCV is often upgraded to handle increased oil flow and pressure demands. Performance parts may include enhanced OCVs designed to provide more precise control over oil distribution, contributing to greater engine responsiveness and power output.

By understanding the interplay between the OCV and these components, engineers and mechanics can better diagnose issues, optimize engine performance, and ensure the longevity of the engine system.

Conclusion

The Cummins 3074003 Oil Control Valve plays a crucial role in the efficient operation of Cummins engines, particularly in commercial trucks. Its integration into the VVT system allows for precise control over oil flow and valve timing, leading to improved engine performance, fuel efficiency, and reduced emissions. Proper installation, maintenance, and understanding of its function within the engine system are essential for maximizing the benefits of this part.

This revised article provides a comprehensive overview of the Cummins 3074003 Oil Control Valve, its purpose, features, benefits, and integration within engine systems. It also includes insights into troubleshooting, maintenance, and the impact on engine performance, supported by relevant references.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.