This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

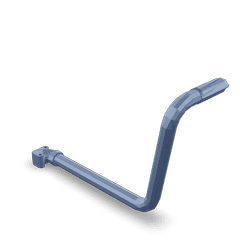

The Lubricating Oil Suction Tube, identified by part number 3086273, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This tube is integral to the engine lubrication system, ensuring that oil is efficiently drawn from the sump and circulated throughout the engine to maintain optimal performance and longevity 1.

Function and Operation

The Lubricating Oil Suction Tube plays a role in the engine lubrication system by facilitating the smooth and consistent flow of oil from the sump to the oil pump. This process is vital for maintaining the necessary lubrication of engine components, which helps in reducing friction and wear. The tube is designed to handle the oil’s viscosity and flow rate, ensuring that the oil pump receives a steady supply of lubricant under various operating conditions 2.

Purpose of the Lubricating Oil Suction Tube

In the operation of a truck, the Lubricating Oil Suction Tube contributes to engine efficiency and longevity by ensuring that engine components remain well-lubricated. This lubrication is crucial for minimizing friction between moving parts, which in turn helps in maintaining engine performance and extending the lifespan of the engine.

Key Features

The Lubricating Oil Suction Tube is constructed from durable materials that can withstand the harsh conditions within an engine compartment. Its design includes features such as a smooth interior to facilitate easy oil flow and a robust connection to the oil pump and sump. These attributes enhance the tube’s functionality and reliability in demanding environments.

Benefits

Using the Lubricating Oil Suction Tube offers several benefits, including improved engine performance due to consistent oil circulation. This consistent lubrication helps in reducing wear and tear on engine components, leading to enhanced reliability and potentially lower maintenance costs over the vehicle’s lifespan.

Installation Process

Installing the Lubricating Oil Suction Tube requires careful attention to ensure proper setup. The process involves securing the tube to both the oil pump and the sump, ensuring there are no leaks or obstructions in the oil flow path. It is important to follow manufacturer guidelines for torque specifications and connection methods to ensure the tube is installed correctly.

Common Issues and Troubleshooting

Common issues with the Lubricating Oil Suction Tube may include leaks, blockages, or damage to the tube itself. Troubleshooting these problems involves inspecting the tube for signs of wear or damage, checking connections for tightness, and ensuring there are no obstructions in the oil flow path. Addressing these issues promptly can help in maintaining the efficiency of the engine lubrication system.

Maintenance Tips

To prolong the lifespan of the Lubricating Oil Suction Tube, regular inspection routines should be conducted to check for signs of wear, leaks, or damage. Cleaning the tube and its connections as part of routine engine maintenance can also help in preventing buildup that may obstruct oil flow. Following manufacturer guidelines for replacement intervals can ensure the tube remains in optimal condition.

About Cummins

Cummins is a reputable manufacturer in the commercial truck industry, known for its wide range of products that include engines, filtration systems, and aftermarket parts. The company’s history of innovation and commitment to quality has established it as a trusted name among truck operators and maintenance professionals. This reputation underscores the reliability and quality of components like the Lubricating Oil Suction Tube.

Cummins Engine Compatibility with Lubricating Oil Suction Tube Part 3086273

The Cummins part 3086273, a Lubricating Oil Suction Tube, is designed to fit seamlessly within specific engine models. This part is integral to the engine’s lubrication system, ensuring that oil is efficiently drawn from the oil pan and circulated throughout the engine to maintain optimal performance and longevity.

QSK19 CM500 and QSK19 CM850 MCRS

The Lubricating Oil Suction Tube part 3086273 is compatible with the QSK19 CM500 and QSK19 CM850 MCRS engines. These engines are part of Cummins’ QSK19 series, which is known for its robust design and high performance in various industrial applications. The part’s design ensures a precise fit and reliable function within these engines, facilitating the smooth operation of the lubrication system.

The QSK19 CM500 and QSK19 CM850 MCRS engines are engineered to handle demanding conditions, and the use of the correct components, such as the lubricating oil suction tube, is crucial for maintaining the engine’s efficiency and durability. The part’s compatibility with these engines underscores Cummins’ commitment to providing high-quality, reliable components that meet the needs of their customers.

Role of Part 3086273 Lubricating Oil Suction Tube in Engine Systems

The lubricating oil suction tube, identified as part 3086273, is integral to the efficient operation of engine systems. This component is responsible for drawing oil from the oil pan and delivering it to the oil pump. The arrangement of the suction tube within the engine system ensures a consistent and reliable flow of oil, which is essential for maintaining proper lubrication of moving parts.

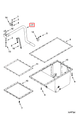

The oil pan serves as the reservoir for the engine’s lubrication system. It collects and stores the oil that circulates through the engine, ensuring that there is always a sufficient supply available for the suction tube to draw from. The design of the oil pan, including its capacity and the placement of the suction tube, plays a significant role in the effectiveness of the lubrication system.

As the suction tube draws oil from the pan, it must be positioned correctly to avoid aeration and ensure a steady stream of oil reaches the pump. The oil, once drawn up by the suction tube, is then pressurized by the oil pump and distributed throughout the engine to lubricate critical components such as bearings, pistons, and camshafts.

The efficiency of the lubrication system depends on the seamless interaction between the oil pan, the suction tube, and the oil pump. Proper maintenance and inspection of these components are necessary to ensure that the engine operates smoothly and efficiently, with minimal wear on its internal parts.

Conclusion

The Lubricating Oil Suction Tube (part #3086273) by Cummins is a critical component in the engine lubrication system, ensuring efficient oil circulation and maintaining engine performance and longevity. Its compatibility with specific Cummins engines, such as the QSK19 CM500 and QSK19 CM850 MCRS, highlights the importance of using the correct components for optimal engine function. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall reliability and efficiency of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.