This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3092366 Oil Seal is a component designed to maintain the integrity of the lubrication system in commercial trucks. Its role is to prevent lubricant leakage and contamination, ensuring the smooth operation of the engine and other mechanical systems.

Basic Concepts of Oil Seals

An oil seal, also known as a shaft seal, is a mechanical device used to prevent the leakage of lubricants from rotating equipment while also keeping contaminants out. It functions by creating a barrier between the rotating and stationary parts of a machine. The importance of oil seals lies in their ability to maintain the cleanliness and efficiency of the lubrication system, which is vital for the longevity and performance of mechanical components 1.

Purpose of the Cummins 3092366 Oil Seal

This Cummins part plays a role in the operation of a truck by maintaining the integrity of the lubrication system. It ensures that lubricants remain within the system, providing necessary lubrication to moving parts, and prevents external contaminants from entering, which could lead to wear and reduced efficiency.

Key Features

This part is characterized by its material composition, typically featuring a durable elastomer for the sealing lip and a robust metal or plastic housing. Its design includes precision-engineered lips that make contact with the shaft to create an effective seal. Unique attributes such as resistance to high temperatures and chemical stability enhance its performance and durability in demanding environments 2.

Benefits

Using this part is associated with several benefits. It contributes to improved engine performance by ensuring consistent lubrication, reduces maintenance costs by minimizing the need for frequent repairs or replacements, and enhances the reliability of the truck’s mechanical systems by preventing lubricant leakage and contamination.

Installation Considerations

Proper installation of this part is vital for ensuring optimal performance and longevity. It should be installed with the correct orientation, ensuring that the sealing lip faces the lubricant. The seal must be seated properly within its housing to avoid damage and ensure a tight fit around the shaft. Careful attention to these details during installation will help maintain the seal’s effectiveness 3.

Troubleshooting Common Issues

Common problems associated with oil seals include leaks and wear. These issues can often be traced back to improper installation, shaft misalignment, or contamination. Troubleshooting involves inspecting the seal and shaft for damage, ensuring proper alignment, and cleaning or replacing components as necessary to resolve these issues effectively.

Maintenance Tips

To prolong the service life of this part and ensure continued reliable operation, regular inspection and maintenance are recommended. This includes checking for signs of wear or damage, ensuring the seal remains properly seated, and adhering to manufacturer-recommended replacement schedules. Keeping the lubrication system clean and well-maintained will also contribute to the seal’s longevity.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product offerings and history of excellence make it a trusted name in the field of diesel engine technology and components.

Cummins Oil Seal 3092366 Compatibility

The Cummins Oil Seal part number 3092366 is designed to fit seamlessly with several engine models, ensuring optimal performance and longevity. This oil seal is specifically engineered to provide a reliable barrier against oil leaks, which is crucial for maintaining engine efficiency and preventing contamination.

QST30 CM2350 T101 and QST30 CM552

This part is compatible with both the QST30 CM2350 T101 and QST30 CM552 engines. These engines, while distinct in their specifications, share common design elements that make this oil seal an ideal fit. The seal’s precision engineering ensures it can effectively seal the critical areas where oil leaks are most likely to occur, thereby protecting the engine’s internal components from oil contamination and ensuring smooth operation.

Installation and Maintenance

Proper installation of this part is essential to maximize its effectiveness. Technicians should follow the manufacturer’s guidelines for installation, ensuring that the seal is correctly aligned and securely fastened. Regular maintenance checks should be performed to inspect the seal for any signs of wear or damage, which could compromise its sealing capabilities. Timely replacement of the oil seal is crucial to prevent potential engine damage due to oil leaks.

Performance Benefits

By using this part, engine operators can expect several performance benefits. The seal helps maintain consistent oil pressure, which is vital for the engine’s lubrication system. Additionally, it reduces the risk of oil contamination, which can lead to increased engine wear and reduced lifespan. The seal’s high-quality materials ensure durability and reliability, making it a cost-effective choice for engine maintenance.

Role of Part 3092366 Oil Seal in Engine Systems

This part is an essential component in various engine systems, ensuring the efficient operation of several key parts.

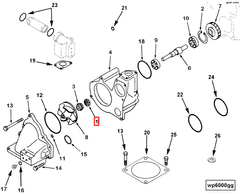

In a Water Pump (WP) Repair Kit, the oil seal plays a significant role in maintaining the integrity of the water pump by preventing coolant leaks. This ensures that the cooling system functions correctly, preventing engine overheating.

For a WP Repair (Major), the oil seal is even more vital. During major repairs, the water pump undergoes extensive servicing, and the oil seal must be in optimal condition to ensure a secure seal between moving and stationary parts. This helps in maintaining the pump’s efficiency and longevity.

In a Water Pump Kit, the oil seal works alongside other components to provide a comprehensive solution for water pump maintenance. It ensures that the pump operates smoothly, with no leaks, which is essential for consistent engine cooling.

When integrated into a Pump, specifically a water pump, the oil seal helps in sealing the shaft, preventing coolant from escaping and contaminants from entering. This maintains the pump’s performance and protects the engine from potential damage due to coolant loss or contamination.

Overall, this part is a fundamental component in these engine systems, contributing to the reliable and efficient operation of the water pump and associated kits.

Conclusion

The Cummins 3092366 Oil Seal is a critical component for maintaining the integrity of lubrication systems in commercial trucks. Its proper installation, maintenance, and timely replacement are essential for ensuring engine efficiency, reducing maintenance costs, and enhancing the reliability of mechanical systems. By understanding the key features, benefits, and compatibility of this part, technicians and operators can better maintain their engines and ensure optimal performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.