3093057

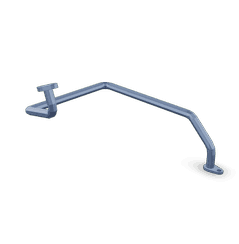

Tur Oil Drain Tube

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbine Oil Drain Tube (3093057) by Cummins is a component designed to facilitate the efficient drainage of turbine oil in heavy-duty trucks. This part is integral to the maintenance and operation of the truck’s engine, ensuring that oil is properly managed within the lubrication system. Its role is significant in preserving engine performance and longevity 1.

Basic Concepts

Turbine oil drain tubes are fundamental components within the lubrication systems of truck engines. They function by providing a pathway for the drainage of used turbine oil, which is crucial for maintaining the cleanliness and efficiency of the lubrication system. Proper drainage helps prevent the buildup of contaminants and ensures that fresh oil can circulate effectively, supporting optimal engine function 2.

Purpose and Function

The Turbine Oil Drain Tube (3093057) plays a role in the operation of a truck by enabling the drainage of turbine oil from the engine. This process is vital for removing oil that has become contaminated with particles and byproducts of combustion. By facilitating the regular replacement of oil, the drain tube contributes to maintaining engine performance and extending the engine’s operational life. It ensures that the lubrication system operates efficiently, reducing friction and wear on engine components 3.

Key Features

The Turbine Oil Drain Tube (3093057) is characterized by several design elements that enhance its performance and durability. It is constructed from materials that are resistant to corrosion and high temperatures, ensuring longevity in demanding operating conditions. The tube’s design allows for easy connection and disconnection, simplifying the oil drainage process. Additionally, it may feature specific fittings or adapters that ensure a secure and leak-free connection to the engine’s lubrication system.

Benefits

Utilizing the Turbine Oil Drain Tube (3093057) offers several advantages. It contributes to improved engine efficiency by ensuring that the lubrication system is free from contaminants. This can lead to reduced maintenance requirements, as clean oil circulates more effectively and causes less wear on engine components. Furthermore, the tube enhances the reliability of the engine in demanding operating conditions, supporting consistent performance over time.

Installation and Compatibility

For the proper installation of the Turbine Oil Drain Tube (3093057), it is important to follow manufacturer guidelines to ensure compatibility with specific truck models and engine configurations. Proper installation involves securing the tube to the engine’s lubrication system in a manner that prevents leaks and ensures efficient oil drainage. Compatibility with the truck’s engine is crucial for optimal performance and should be verified before installation.

Maintenance and Troubleshooting

Maintaining the Turbine Oil Drain Tube (3093057) involves regular inspection for signs of wear or damage, ensuring that all connections are secure, and verifying that oil drainage is occurring as expected. Common issues may include leaks or blockages, which can be addressed by tightening connections or cleaning the tube. Regular maintenance helps ensure the tube continues to function effectively, supporting the overall health of the engine’s lubrication system.

Safety Considerations

When working with the Turbine Oil Drain Tube (3093057), it is important to observe safety precautions and best practices. This includes ensuring that the engine is cool before attempting any maintenance or installation procedures to avoid burns from hot components. Proper handling and storage of the tube, as well as adherence to disposal procedures for used oil, are also critical to maintaining a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company is renowned for its commitment to quality, reliability, and performance across its product offerings, including components like the Turbine Oil Drain Tube (3093057).

Turbine Oil Drain Tube for Cummins Engines

The Turbine Oil Drain Tube, part number 3093057, is a critical component in the maintenance and operation of several Cummins engines. This part is integral to the oil management system, ensuring that oil is properly drained from the turbine section of the engine.

QST30 CM552 Engines

In the QST30 CM552 engines, the Turbine Oil Drain Tube is essential for maintaining the integrity of the oil system. This part facilitates the removal of oil from the turbine, preventing oil accumulation that could lead to overheating and potential engine damage. The design of the 3093057 ensures a secure fit and efficient oil drainage, contributing to the overall reliability and performance of the engine.

Grouping of Engines

The Turbine Oil Drain Tube is compatible with a range of Cummins engines, including but not limited to, the QST30 CM552 series. This part is engineered to meet the specific requirements of these engines, ensuring optimal performance and longevity. The compatibility of the 3093057 across various engine models underscores its versatility and importance in the maintenance of Cummins engines.

Role of Part 3093057 Turbine Oil Drain Tube in Engine Systems

The Turbine Oil Drain Tube, identified by part number 3093057, is an essential component in the maintenance and operation of engine systems, particularly those involving turbochargers. This component is integral to the efficient management of oil within the turbocharger system.

Integration with Turbocharger Systems

In turbocharger applications, the Turbine Oil Drain Tube facilitates the removal of used oil from the turbocharger’s lubrication system. This tube is connected to the turbocharger’s oil supply lines, allowing for the periodic draining of oil that has lubricated the turbocharger’s bearings and other moving parts. Regular drainage ensures that the oil does not become contaminated with metal particles or other debris, which could lead to increased wear and reduced efficiency of the turbocharger.

Interaction with Plumbing Systems

The Turbine Oil Drain Tube also plays a significant role in the overall plumbing of the engine system. It is typically connected to the engine’s oil return system, allowing the drained oil to be safely returned to the oil sump or reservoir. This connection is vital for maintaining the correct oil levels within the engine and ensuring that the oil can be recirculated and re-filtered as needed.

Maintenance and Operational Efficiency

By enabling the efficient drainage and return of oil, the Turbine Oil Drain Tube contributes to the maintenance and operational efficiency of the engine system. It helps in keeping the oil clean and at optimal levels, which is essential for the longevity and performance of both the turbocharger and the engine itself. Regular use of this component as part of maintenance routines can prevent oil-related issues that might otherwise lead to costly repairs or downtime.

Conclusion

The Turbine Oil Drain Tube (3093057) by Cummins is a vital component in the maintenance and operation of heavy-duty truck engines. Its role in facilitating the efficient drainage of turbine oil contributes to the cleanliness and efficiency of the lubrication system, supporting optimal engine function and longevity. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the benefits of this part.

-

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023.

↩ -

Automotive Maintenance: Light Repair, Rob Thompson, Cengage Learning, 2019.

↩ -

Charging the Internal Combustion Engine, Hermann Hiereth, Peter Prenninger and Klaus W Drexl, Springer, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.