This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Supply Tube, part #3093343, manufactured by Cummins, is designed to facilitate the efficient distribution of lubricating oil within the engine of heavy-duty trucks. This part is integral to maintaining the smooth operation and longevity of the engine by ensuring that oil reaches all necessary components in a timely and controlled manner.

Basic Concepts of Lubricating Oil Supply Tubes

A Lubricating Oil Supply Tube is a conduit within the engine lubrication system that directs oil from the oil pump to various engine parts that require lubrication. Its function is to maintain a consistent flow of oil, which reduces friction between moving parts, dissipates heat, and removes contaminants. This contributes to the overall performance and durability of the engine by minimizing wear and tear on critical components 1.

Purpose of the Lubricating Oil Supply Tube

The Lubricating Oil Supply Tube plays a role in the operation of a truck by facilitating the flow of lubricating oil to various engine components. It ensures that oil is delivered efficiently to areas such as the crankshaft, camshaft, and valve train, which are essential for the engine’s operation. By maintaining proper lubrication, this tube helps to protect these components from excessive wear and damage 2.

Key Features

The Lubricating Oil Supply Tube is constructed from high-quality materials that offer resistance to corrosion and high temperatures. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to withstand the pressures and vibrations inherent in heavy-duty truck engines, enhancing its performance and durability.

Benefits

Using the Lubricating Oil Supply Tube can lead to improved engine efficiency, as proper lubrication reduces friction and allows components to operate more smoothly. This can result in reduced wear and tear on engine parts, leading to extended engine life. Furthermore, the reliable delivery of oil contributes to the overall reliability of the truck, ensuring consistent performance under various operating conditions.

Installation Process

Installing the Lubricating Oil Supply Tube requires careful attention to detail to ensure optimal performance and longevity. The process involves disconnecting the old tube, cleaning the area to remove any debris, and then fitting the new tube into place using the appropriate tools. It is important to follow manufacturer guidelines to avoid damage to the tube or surrounding components. Proper torque specifications should be adhered to when securing connections to prevent leaks.

Troubleshooting Common Issues

Common issues with the Lubricating Oil Supply Tube may include leaks or blockages. If a leak is detected, it is important to identify the source and address it promptly to prevent oil loss and potential engine damage. Blockages can be caused by contaminants in the oil, and may require cleaning or replacement of the tube. Regular inspections can help to identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

To keep the Lubricating Oil Supply Tube in optimal condition, regular maintenance practices should be followed. This includes periodic inspections for signs of wear, leaks, or damage. Cleaning the tube and its connections can help to prevent blockages and ensure a consistent flow of oil. Replacement guidelines should be consulted to determine when the tube should be replaced based on its condition and the manufacturer’s recommendations.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance engine components. The company’s product offerings span a wide range of industries, including transportation, construction, and power generation, demonstrating its versatility and expertise in the automotive industry.

Cummins Engine Compatibility with Lubricating Oil Supply Tube Part 3093343

The Cummins-manufactured Lubricating Oil Supply Tube part number 3093343 is designed to fit seamlessly within a range of Cummins engines, ensuring optimal lubrication and performance. This part is integral to the engine’s operation, providing a reliable conduit for oil flow from the oil reservoir to the engine’s moving parts.

QST30 CM552 Engines

The part 3093343 is specifically engineered to integrate with the QST30 CM552 engines. These engines are known for their robust design and efficiency, making them suitable for various industrial applications. The lubricating oil supply tube ensures that the engine’s internal components are adequately lubricated, reducing friction and wear, and contributing to the engine’s longevity and reliability.

Grouping of Compatible Engines

While the primary focus here is on the QST30 CM552 engines, it is important to note that the lubricating oil supply tube part 3093343 is also compatible with other Cummins engines within the same engine family. This compatibility is due to the standardized design and engineering principles that Cummins employs across its engine lineup. By using the same part number for similar applications, Cummins ensures ease of maintenance and repair, allowing technicians to use a single part across multiple engine models.

This compatibility extends to other engines within the Cummins portfolio, where the design and function of the lubricating oil supply tube remain consistent. This standardization facilitates efficient inventory management and reduces the complexity of parts procurement for maintenance and repair operations.

Role of Part 3093343 Lubricating Oil Supply Tube in Engine Systems

The lubricating oil supply tube, identified by part number 3093343, is a component in maintaining the operational integrity of various engine systems. Its primary function is to deliver a consistent flow of lubricating oil to critical engine components, ensuring smooth operation and longevity.

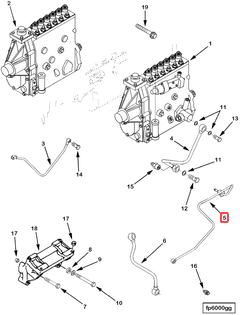

Integration with the Fuel Injection Pump

In engines equipped with a fuel injection pump, the lubricating oil supply tube plays a significant role. The fuel injection pump relies on precise mechanical movements to deliver fuel at the correct pressure and timing. Consistent lubrication is necessary to reduce friction between moving parts, prevent wear, and maintain the pump’s efficiency. The lubricating oil supply tube ensures that the fuel injection pump receives a steady supply of oil, which is vital for its reliable operation.

Supporting Other Engine Components

Beyond the fuel injection pump, the lubricating oil supply tube is integral to the lubrication of other engine components such as the crankshaft, camshaft, and valve train. These parts experience high levels of stress and friction during engine operation. The tube facilitates the distribution of oil to these areas, promoting efficient lubrication and cooling, which in turn enhances the overall performance and durability of the engine.

Enhancing System Reliability

The consistent oil flow provided by the lubricating oil supply tube contributes to the reliability of the entire engine system. By ensuring that all moving parts are adequately lubricated, the tube helps prevent premature wear and potential failures. This reliability is particularly important in high-stress environments where engine performance is paramount.

Conclusion

The Lubricating Oil Supply Tube (part 3093343) is a key component in the lubrication system, supporting the efficient operation of the fuel injection pump and other critical engine parts. Its role in maintaining consistent oil flow is essential for the longevity and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.