This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

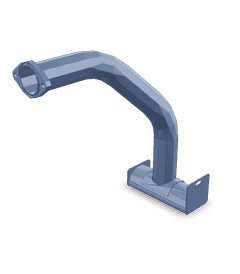

The Lubricating Oil Suction Tube, identified by part number 3094396, is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This tube is integral to the engine lubrication system, facilitating the circulation of oil to various engine components. Its role ensures that engines operate smoothly and efficiently, contributing to the overall performance and longevity of the vehicle 3.

Function and Operation

The Lubricating Oil Suction Tube operates within the engine lubrication system by drawing oil from the oil pan and directing it towards the oil pump. This process is vital for maintaining a consistent supply of lubricant to critical engine parts, such as bearings, pistons, and camshafts. By ensuring these components are adequately lubricated, the tube helps in reducing friction and wear, thereby supporting optimal engine performance and efficiency 1.

Key Features

The design and construction of the Lubricating Oil Suction Tube are tailored to meet the demanding requirements of heavy-duty engines. Crafted from durable materials, the tube is built to withstand high pressures and temperatures. Its structural integrity is enhanced by precise manufacturing processes, ensuring a reliable fit and function within the engine system. Unique design elements, such as reinforced joints and a smooth interior, further contribute to its effectiveness in oil circulation 2.

Benefits

Incorporating the Lubricating Oil Suction Tube into the engine system offers several advantages. It contributes to improved engine lubrication, which is crucial for minimizing wear on engine components. This, in turn, can lead to extended engine life and enhanced overall performance and reliability of the truck. The tube’s efficient design also aids in maintaining optimal engine operating temperatures, further supporting engine health and efficiency 3.

Installation and Compatibility

For the Lubricating Oil Suction Tube to function correctly, proper installation is paramount. It is designed to be compatible with specific Cummins engine models, ensuring a precise fit and optimal performance. Before installation, it is important to verify compatibility with the engine model and follow manufacturer guidelines for preparatory steps, which may include cleaning the installation area and inspecting the tube for any damage 4.

Maintenance and Troubleshooting

Routine maintenance of the Lubricating Oil Suction Tube is essential for ensuring its effective operation. This includes regular inspections for signs of wear or damage and ensuring there are no obstructions in the oil flow path. Troubleshooting common issues, such as leaks or blockages, involves checking connections for tightness and clearing any debris from the tube. Adhering to a maintenance schedule can help prevent more serious problems and ensure the longevity of the component 3.

Safety Considerations

When working with the Lubricating Oil Suction Tube, observing safety protocols is crucial. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against oil spills and potential hazards. Additionally, ensuring the engine is cool before beginning any work on the lubrication system can help prevent burns or other injuries. Awareness of the potential for oil spills and the importance of proper disposal of used oil are also key safety considerations 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation within the commercial truck industry. Its product offerings span a wide range of applications, from on-highway to off-highway and industrial uses, demonstrating a commitment to meeting the diverse needs of its customers with reliable and efficient solutions 4.

Conclusion

The Lubricating Oil Suction Tube (part number 3094396) plays a critical role in the lubrication system of Cummins engines, ensuring efficient oil circulation and contributing to the engine’s overall performance and longevity. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this component.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ ↩ ↩ ↩ -

Cummins Inc. (n.d.). Owners Manual for QSL9 CM2250. Bulletin Number 2883350.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.