This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3095781 Oil Cooler is a component designed to maintain optimal oil temperature in commercial trucks. Its role is significant in ensuring the engine operates efficiently and reliably under various conditions.

Basic Concepts of Oil Coolers

An oil cooler is a device that helps regulate the temperature of engine oil. It functions by transferring excess heat from the oil to the surrounding air or coolant, thus maintaining the oil within a specified temperature range. This regulation is vital for preserving engine performance, as oil that is too hot can break down and lose its lubricating properties, while oil that is too cold can become thick and less effective 1.

Purpose of the Cummins 3095781 Oil Cooler

This Cummins part is specifically designed to regulate oil temperature in trucks equipped with Cummins engines. By maintaining the oil at an optimal temperature, it helps ensure that the engine operates within its designed parameters, which can contribute to improved efficiency, longevity, and reliability of the engine 2.

Key Features

This part is constructed with a focus on durability and efficiency. Its design incorporates high-quality materials that are resistant to corrosion and wear. Unique attributes such as its compact size and efficient heat exchange capabilities enhance its performance, allowing it to effectively manage oil temperatures even under demanding conditions.

Benefits of Using the Cummins 3095781 Oil Cooler

Utilizing this part can lead to several advantages. These include improved engine efficiency due to optimal oil viscosity, enhanced engine longevity as a result of reduced wear on engine components, and increased reliability through consistent oil temperature regulation 3.

Installation and Integration

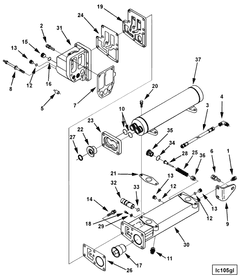

Proper installation of this part is crucial for its effective operation. It should be integrated into the truck’s engine system according to the manufacturer’s guidelines to ensure compatibility and optimal performance. Best practices during installation include careful alignment, secure fastening, and verification of all connections to prevent leaks or inefficiencies.

Maintenance and Care

Routine maintenance of this part is important for ensuring its continued optimal performance. This includes regular inspection for signs of wear or damage, cleaning to remove any buildup that could impede heat exchange, and following recommended service intervals for fluid changes and component checks.

Troubleshooting Common Issues

Common issues with oil coolers may include leaks or reduced efficiency. Troubleshooting steps can involve inspecting for physical damage, checking for proper installation and alignment, and ensuring that all connections are secure. Solutions may range from simple repairs or adjustments to replacement of the cooler if it is beyond repair.

Performance Enhancements

There are potential performance enhancements or upgrades that can be made to this part. These may include modifications to improve heat exchange efficiency or the addition of monitoring systems to provide real-time data on oil temperature, which can further contribute to engine efficiency and reliability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a strong reputation in the industry, Cummins is committed to delivering high-quality components that meet the demanding requirements of commercial and industrial applications.

Role of Part 3095781 Oil Cooler in Engine Systems

This part is an essential component in maintaining the optimal operating temperature of engine oil. It is integrated into the engine’s lubrication system, where it works in conjunction with several key components to ensure efficient and reliable engine performance.

Integration with the Engine Oil Cooler

The primary function of the 3095781 oil cooler is to dissipate excess heat from the engine oil. This is achieved through a heat exchange process where the hot oil passes through a series of tubes or fins within the cooler. As the oil flows through these pathways, it releases heat to the surrounding air or coolant, depending on the cooler’s design.

In systems where an engine oil cooler is present, the 3095781 oil cooler often complements this component by providing additional cooling capacity. The engine oil cooler typically handles the initial cooling of the oil as it exits the engine, while the 3095781 oil cooler further reduces the temperature before the oil is recirculated back into the engine. This two-stage cooling process ensures that the oil maintains a consistent viscosity and lubricating properties, which are vital for the longevity and efficiency of the engine’s moving parts 4.

Interaction with the Lubrication System

Within the lubrication system, the 3095781 oil cooler is positioned in the oil return line, after the oil has passed through the engine and before it returns to the oil pan. This placement allows the cooler to effectively manage the temperature of the oil as it cycles through the engine. The regulated temperature of the oil contributes to reduced friction and wear on critical engine components such as bearings, pistons, and cylinder walls.

Contribution to Overall Engine Efficiency

By ensuring that the engine oil remains within the desired temperature range, the 3095781 oil cooler plays a significant role in the overall efficiency of the engine. Properly cooled oil enhances the engine’s ability to operate under varying loads and conditions, leading to improved performance and fuel economy. Additionally, the consistent temperature of the oil helps in maintaining the integrity of the oil’s additives, which are essential for corrosion protection and debris suspension.

Conclusion

In summary, the 3095781 oil cooler is a vital component in the engine’s thermal management system, working seamlessly with the engine oil cooler and the lubrication system to maintain optimal engine oil temperature and ensure the engine operates efficiently and reliably.

-

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659634.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.