This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

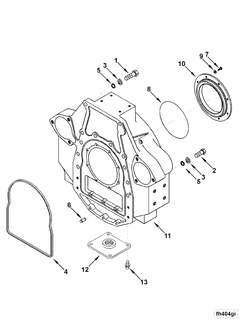

The Cummins 3099421 Oil Seal is a critical component in commercial trucks, designed to maintain the integrity of the lubrication system by preventing oil leakage and blocking contaminants from entering sensitive engine areas. This part plays a significant role in ensuring the smooth operation and longevity of truck engines.

Basic Concepts of Oil Seals

Oil seals are mechanical components used across various machinery to prevent lubricant leakage and keep out contaminants such as dirt and dust. They create a barrier between moving and stationary parts within a system. Typically made from materials like rubber or synthetic compounds, oil seals are engineered to withstand the pressures and temperatures encountered in engine environments 1.

Purpose of the Cummins 3099421 Oil Seal

This Cummins part is specifically engineered to fit within the truck’s engine system, interfacing with rotating shafts or other moving parts. Its primary role is to seal the area around these parts, ensuring that lubricants remain within the system and contaminants are kept out. This seal is located in areas where maintaining a clean and lubricated environment is crucial for efficient engine operation.

Key Features

The Cummins 3099421 Oil Seal is constructed with durability and performance in mind. It is made from high-quality materials that offer resistance to wear and the effects of high temperatures. Design elements such as reinforced edges and precise manufacturing tolerances enhance its ability to maintain a seal under various operating conditions. These features contribute to the seal’s effectiveness in demanding truck engine environments 2.

Benefits

Using the Cummins 3099421 Oil Seal in truck engines can lead to improved performance and efficiency. By ensuring that lubricants remain in place and contaminants are excluded, the seal helps maintain optimal engine conditions. This can result in extended component life and reduced maintenance requirements, contributing to the overall efficiency of truck operations 3.

Installation and Maintenance

Proper installation of the Cummins 3099421 Oil Seal is vital for its performance. It should be fitted according to manufacturer guidelines to ensure a secure and effective seal. Regular maintenance, including inspections for wear or damage, is recommended to prolong the life of the seal and ensure continued efficient operation. Following these practices can help prevent issues such as oil leaks or engine damage 4.

Troubleshooting Common Issues

Common problems with oil seals include leaks and wear, which can arise from improper installation, excessive wear, or damage. Troubleshooting these issues involves inspecting the seal for signs of damage, ensuring it is correctly installed, and replacing it if necessary. Regular inspections and timely replacements are important for maintaining the integrity of the engine’s lubrication system 5.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. The company is committed to advancing technology and sustainability in the engine and power generation industries, providing reliable and efficient solutions for its customers.

Conclusion

The Cummins 3099421 Oil Seal is an essential component for maintaining the efficiency and longevity of truck engines. Its design and features ensure it can withstand the demanding conditions of commercial truck operations, contributing to improved performance and reduced maintenance requirements. Proper installation and regular maintenance are key to maximizing the benefits of this part.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4021538.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.