This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

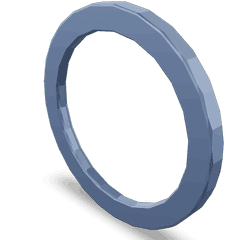

The Cummins 3171135 Oil Seal is a critical component in commercial trucks, designed to prevent lubricant leakage and contaminant ingress. This ensures the operational integrity of the truck’s engine or transmission, protecting moving parts from wear and maintaining system efficiency 3.

Basic Concepts of Oil Seals

An oil seal, or rotary shaft seal, is a mechanical device that prevents lubricant leakage and keeps out contaminants. It creates a barrier between the rotating shaft and the stationary housing, typically using an elastomeric lip that contacts the shaft. This barrier is essential for maintaining the cleanliness and lubrication of internal components, which is fundamental to machinery longevity and performance 2.

Purpose of the 3171135 Oil Seal

The Cummins 3171135 Oil Seal is designed to seal the interface between rotating and stationary parts within the engine or transmission. Located in areas where shafts pass through housings, this seal maintains system integrity by ensuring lubricants remain within the system and contaminants are kept out. This helps preserve the efficiency and longevity of engine or transmission components 3.

Key Features

The Cummins 3171135 Oil Seal is characterized by several features that enhance its performance and durability. Made from high-quality elastomeric materials, it offers excellent resistance to oil, heat, and wear. The design includes a spring-energized lip that maintains contact with the shaft under various operating conditions. Additional features may include anti-rotation devices or secondary sealing elements to improve effectiveness in demanding environments 2.

Benefits of Using the 3171135 Oil Seal

Utilizing the Cummins 3171135 Oil Seal offers several advantages. It contributes to improved engine or transmission longevity by retaining lubricants within the system, reducing the risk of component wear. Enhanced efficiency is another benefit, as the seal helps maintain optimal lubrication conditions. Additionally, the use of this oil seal can lead to reduced maintenance requirements, as its durable design minimizes the need for frequent replacements 3.

Installation and Maintenance

Proper installation of the Cummins 3171135 Oil Seal is crucial for its effective performance. Guidelines recommend ensuring that the seal is correctly aligned and seated within its housing to avoid damage during installation. Regular maintenance practices include inspecting the seal for signs of wear or failure, such as leaks or contamination, and replacing it as necessary to maintain system integrity. Adhering to these practices helps in prolonging the life of the seal and the components it protects 1.

Troubleshooting Common Issues

Typical problems associated with oil seals include leaks and contamination. Leaks may occur due to wear, improper installation, or damage to the seal. Contamination can enter the system through a compromised seal, leading to increased wear on internal components. Diagnostic actions involve inspecting the seal for physical damage and checking for proper alignment and seating. Remedial actions may include cleaning the seal and its housing, ensuring proper installation, or replacing the seal if it is worn or damaged 2.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its product range, which includes high-quality components like the 3171135 Oil Seal. This background underscores the reliability and performance of Cummins products in demanding applications 3.

Role of Part 3171135 Oil Seal in Engine Systems

The 3171135 Oil Seal is instrumental in maintaining the integrity and efficiency of various engine components. In the drive system, this oil seal ensures that lubricants remain within the designated areas, preventing leaks that could lead to friction and wear on moving parts. By maintaining a consistent lubricant level, the seal helps in reducing the operational stress on the drive components, thereby enhancing their longevity and performance.

In the fan system, the 3171135 Oil Seal plays a significant role in safeguarding the fan bearings. The seal prevents contaminants such as dirt and debris from entering the bearing area, which could otherwise cause excessive wear and potential failure. Additionally, it retains the lubricant within the bearing, ensuring smooth rotation and efficient cooling of the engine.

In the fan hub, the oil seal is equally important. It ensures that the lubricant stays within the hub, providing necessary friction reduction between the rotating parts. This not only aids in the smooth operation of the fan hub but also protects it from premature wear. The seal’s ability to keep out external contaminants further contributes to the reliability and durability of the fan hub.

Overall, the 3171135 Oil Seal is a key component in preserving the functionality and efficiency of these engine systems, ensuring they operate under optimal conditions 3.

Conclusion

The Cummins 3171135 Oil Seal is a vital component in commercial trucks, ensuring the integrity and efficiency of engine and transmission systems. Its design and features contribute to the longevity and performance of these systems by preventing lubricant leakage and contaminant ingress. Proper installation and maintenance are essential for maximizing the benefits of this oil seal, making it a reliable choice for demanding applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.