This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3252455 Oil Transfer Connection is a component designed for use in commercial trucks. It facilitates the transfer of oil within the lubrication system, ensuring that various engine parts receive adequate lubrication for optimal performance and longevity. This part is integral to maintaining the efficiency and reliability of heavy-duty trucks 1.

Basic Concepts of Oil Transfer Connection

Oil transfer connections in heavy-duty trucks are vital components of the lubrication system. They enable the movement of oil from the oil pan to other parts of the engine, ensuring that critical components such as bearings, pistons, and cylinders are properly lubricated. This lubrication reduces friction, wear, and heat, contributing to the overall efficiency and durability of the engine 2.

Purpose of the Cummins 3252455 Oil Transfer Connection

The Cummins 3252455 Oil Transfer Connection plays a specific role in the operation of a truck by facilitating the efficient transfer of oil within the lubrication system. It ensures that oil reaches all necessary engine components, maintaining their performance and protecting them from wear and damage. This part is designed to work seamlessly within the truck’s lubrication system, enhancing the engine’s reliability and efficiency 3.

Key Features

The Cummins 3252455 Oil Transfer Connection is characterized by several key features that enhance its performance. It is made from durable materials that can withstand the high pressures and temperatures of the engine environment. The design includes precise fittings and connections to ensure a secure and leak-free transfer of oil. Additionally, it may feature unique characteristics such as reinforced seals or specialized coatings to further improve its durability and efficiency 4.

Benefits

The Cummins 3252455 Oil Transfer Connection offers several advantages in heavy-duty applications. It provides improved lubrication efficiency, ensuring that all engine components receive the necessary oil for optimal performance. Its durable construction contributes to the longevity of the part, reducing the need for frequent replacements. Additionally, the reliable performance of this connection enhances the overall reliability of the truck’s lubrication system 1.

Installation Process

Proper installation of the Cummins 3252455 Oil Transfer Connection is crucial for its effective function. The installation process involves several steps:

- Ensure the engine is cool and the oil system is depressurized.

- Locate the appropriate connection points within the lubrication system.

- Clean the connection points to remove any debris or old gasket material.

- Apply a compatible sealant to the threads of the connection, if required.

- Carefully thread the oil transfer connection into place, ensuring it is securely fastened.

- Check for any leaks after installation and make adjustments as necessary 2.

Common Issues and Troubleshooting

Typical problems that may arise with the Cummins 3252455 Oil Transfer Connection include leaks, loose connections, and wear on the fittings. To address these issues:

- Inspect the connection regularly for signs of leaks or wear.

- Tighten any loose connections to ensure a secure fit.

- Replace worn or damaged fittings to maintain the integrity of the lubrication system.

- Use compatible sealants and lubricants to prevent leaks and ensure smooth operation 3.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3252455 Oil Transfer Connection, follow these maintenance tips:

- Regularly inspect the connection for signs of wear, leaks, or damage.

- Clean the connection points during oil changes to remove any buildup or debris.

- Use high-quality sealants and lubricants compatible with the connection materials.

- Follow the manufacturer’s recommendations for inspection and maintenance intervals 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. Founded in 1919, Cummins has a long-standing reputation for innovation, quality, and reliability in the automotive industry. The company’s product offerings cater to various sectors, including commercial vehicles, construction, agriculture, and power generation, providing solutions that meet the demanding requirements of heavy-duty applications 1.

Cummins Oil Transfer Connection Part 3252455

The Cummins Oil Transfer Connection part number 3252455 is a critical component in the engine’s lubrication system. This part is designed to facilitate the transfer of oil between different parts of the engine, ensuring that all moving components are adequately lubricated. The design and functionality of this part are crucial for maintaining engine performance and longevity 2.

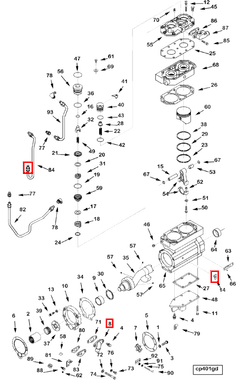

Application in K19 Engines

In the K19 engine series, the Oil Transfer Connection part 3252455 is integral to the engine’s lubrication network. This part ensures that oil is efficiently distributed to various engine components, reducing friction and wear. The precision engineering of this part is essential for maintaining the high standards of performance expected from Cummins engines 3.

Compatibility with Cummins Engines

The Oil Transfer Connection part 3252455 is compatible with a range of Cummins engines, including but not limited to the K19 series. Its design allows it to fit seamlessly into the engine’s architecture, providing a reliable connection point for oil transfer. This compatibility extends to other Cummins engine models where similar lubrication requirements are present 4.

Importance in Engine Performance

The proper functioning of the Oil Transfer Connection part 3252455 is vital for the overall health of the engine. By ensuring that oil is correctly routed and distributed, this part helps to prevent overheating and mechanical failure. Its role in the engine’s lubrication system cannot be overstated, as it directly impacts the engine’s efficiency and durability 1.

Installation and Maintenance

When installing the Oil Transfer Connection part 3252455, it is important to follow the manufacturer’s guidelines to ensure a secure and leak-free connection. Regular maintenance checks should be performed to verify that the part is in good condition and functioning as intended. Any signs of wear or damage should be addressed promptly to avoid potential engine issues 2.

Role of Part 3252455 Oil Transfer Connection in Engine Systems

The Part 3252455 Oil Transfer Connection is integral to the seamless operation of various engine systems, ensuring efficient oil management and transfer. Here’s how it interfaces with key components:

Compressor Systems

In compressor systems, the Oil Transfer Connection facilitates the movement of lubricating oil between the compressor and its associated oil reservoir. This ensures that the compressor remains adequately lubricated, reducing friction and wear on moving parts. The connection is designed to handle the specific pressures and flow rates required by the compressor, maintaining optimal performance and longevity 3.

Air Compressor Oil Drain Plumbing

For air compressors, the Oil Transfer Connection plays a significant role in the oil drain plumbing system. It allows for the efficient drainage of used oil from the compressor, which is essential for maintaining clean oil levels and preventing contamination. This connection ensures that oil is promptly and safely transferred to the drain system, facilitating regular maintenance and reducing downtime 4.

Lubricating Oil Plumbing

In lubricating oil plumbing systems, the Oil Transfer Connection is responsible for the consistent flow of oil to various engine components that require lubrication. This includes bearings, pistons, and other moving parts. The connection ensures that oil is distributed evenly, minimizing the risk of lubrication failure and enhancing the overall efficiency of the engine 1.

General Plumbing Systems

Within general plumbing systems of an engine, the Oil Transfer Connection acts as a vital link between different oil circuits. It enables the transfer of oil between the lube pump, oil reservoirs, and various engine components. This ensures that all parts requiring lubrication receive an adequate supply, contributing to the smooth operation and reliability of the engine 2.

Lube Pump Integration

The integration of the Oil Transfer Connection with the lube pump is essential for maintaining consistent oil pressure throughout the engine. The connection ensures that oil is efficiently pumped from the reservoir to the points of lubrication. This is particularly important in high-performance engines where precise oil delivery is necessary to meet demanding operational requirements 3.

Conclusion

In summary, the Cummins 3252455 Oil Transfer Connection is a key component in ensuring the proper functioning of engine systems by facilitating the efficient transfer and management of lubricating oil. Its role in maintaining engine performance and longevity cannot be overstated, making it an essential part of the lubrication system in heavy-duty trucks and engines 4.

-

Clive Gifford, Cars Encyclopedia, DK Publishing, 2014.

↩ ↩ ↩ ↩ ↩ -

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ ↩ ↩ ↩ ↩ -

Tim Giles, Automotive Engines Diagnosis Repair and Rebuilding, Cengage Learning, 2019.

↩ ↩ ↩ ↩ ↩ -

Ed Sobey, A Field Guide to Automotive Technology, Chicago Review Press, 2009.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.