This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

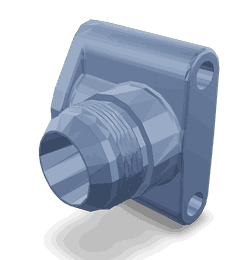

The Oil Suction Connection 3351035, a component manufactured by Cummins, is integral to the operation of heavy-duty trucks, particularly within the lubrication system. Understanding its purpose and functionality is essential for maintaining engine efficiency and longevity.

Basic Concepts of Oil Suction Connection

An oil suction connection within a truck engine’s lubrication system facilitates the flow of oil from the oil pan to the engine’s lubrication points. This ensures a consistent oil supply necessary for engine operation, reducing friction, cooling the engine, and removing contaminants 1.

Purpose of the 3351035 Oil Suction Connection

The 3351035 Oil Suction Connection is designed to enhance the operation of a truck’s lubrication system by ensuring effective oil circulation throughout the engine. This contributes to maintaining engine performance and longevity 2.

Key Features

This Cummins part is characterized by a robust material composition that resists wear and corrosion, a design that ensures a secure fit within the engine system, and unique characteristics that improve its functionality. These features contribute to the part’s ability to withstand the demanding conditions of heavy-duty truck operation.

Benefits

Utilizing the 3351035 Oil Suction Connection offers benefits such as improved engine efficiency through consistent and reliable oil flow, reduced maintenance requirements due to its durable construction, and enhanced overall engine performance and longevity.

Installation Process

Installing the 3351035 Oil Suction Connection requires careful attention to detail. The process involves cleaning the installation area, inspecting the connection for damage, and using tools such as wrenches and sealants. Following the manufacturer’s guidelines for torque specifications and alignment is crucial for a proper installation. Verifying the connection’s integrity after installation helps prevent leaks or malfunctions.

Troubleshooting Common Issues

Common issues with the 3351035 Oil Suction Connection include leaks or blockages. Troubleshooting involves inspecting the connection for wear, damage, or misalignment. Addressing leaks may require re-sealing or replacing the connection, while blockages can often be resolved by cleaning the oil passages. Regular inspections and maintenance can help identify and resolve these issues promptly.

Maintenance Tips

To ensure the longevity and optimal performance of the 3351035 Oil Suction Connection, regular maintenance practices are recommended. This includes periodic inspections for wear or damage, cleaning the connection to prevent blockages, and ensuring that all seals and fittings remain intact. Adhering to these maintenance tips helps maintain the efficiency of the lubrication system and the overall performance of the engine.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for producing high-quality diesel engines and components. The company’s commitment to quality and performance is evident in its extensive product line, which includes engines, filtration systems, and aftermarket parts, all engineered to deliver reliability and efficiency.

Cummins Engine Part 3351035: Oil Suction Connection

The Cummins part number 3351035, identified as an Oil Suction Connection, is a critical component in the engine’s lubrication system. This part facilitates the flow of oil from the oil pan to the oil pump, ensuring that the engine’s moving parts are adequately lubricated.

Application in Cummins Engines

The Oil Suction Connection (part number 3351035) is compatible with several Cummins engine models, including the N14 MECHANICAL. This part is integral to the N14 MECHANICAL engine, where it connects the oil pan to the oil pump. The connection ensures a steady and uninterrupted flow of oil, which is essential for maintaining engine performance and longevity. The design and material of the Oil Suction Connection are engineered to withstand high pressures and temperatures, ensuring durability and reliability in demanding applications.

Compatibility and Usage

The Oil Suction Connection is a versatile component that fits seamlessly into various Cummins engine configurations. Its design allows for easy installation and maintenance, making it a preferred choice for technicians and engineers working with Cummins engines. The part’s compatibility with the N14 MECHANICAL engine underscores its importance in maintaining the engine’s operational efficiency and reliability.

Role of Part 3351035 Oil Suction Connection in Engine Systems

The Part 3351035 Oil Suction Connection is an integral component in the lubrication system of various engine setups. It interfaces with several key components to ensure the efficient circulation of oil, which is essential for the engine’s performance and longevity.

Integration with Key Components

-

Oil Pan: The oil suction connection is typically mounted on the oil pan, which serves as the reservoir for the engine’s lubricating oil. This connection allows for the suction of oil from the pan, ensuring a consistent supply to the engine’s moving parts.

-

Suction Hose and Hose Assembly: Connected to the oil suction connection, the suction hose or hose assembly facilitates the transfer of oil from the oil pan to the lubricating oil pump. This hose must be securely attached to prevent leaks and ensure a steady flow of oil.

-

Lubricating Oil Assembly Connection: This connection point is where the oil suction connection interfaces with the broader lubricating oil assembly. It ensures that the oil is correctly routed through the system, maintaining pressure and flow rates necessary for optimal engine operation.

-

Lub Oil Suction: The lub oil suction system relies on the oil suction connection to draw oil from the pan. This system is designed to handle the viscosity and volume of the lubricating oil, ensuring that it is effectively circulated throughout the engine.

-

Pan and Oil Pan: Beyond just the oil pan, the overall pan structure (which may include baffles and other features) works in conjunction with the oil suction connection to manage oil levels and prevent aeration, which can lead to inefficient lubrication.

Conclusion

In summary, the Part 3351035 Oil Suction Connection plays a significant role in the lubrication system by ensuring a reliable and consistent flow of oil from the oil pan to the engine’s critical components. Its proper installation and maintenance are essential for the engine’s efficient operation and durability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.