This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

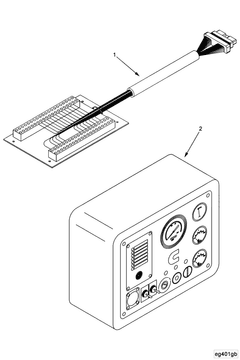

Understanding the Cummins 3393003 Oil Pressure Gauge

Introduction to Oil Pressure Gauges

Oil pressure gauges are critical components in the engine management systems of commercial trucks. They provide real-time data on the oil pressure within the engine, which is essential for maintaining engine health and preventing catastrophic failures. Understanding how these gauges work and their importance can significantly enhance the operational efficiency and longevity of heavy-duty trucks 1.

Basic Concepts of Oil Pressure Gauges

An oil pressure gauge operates by measuring the pressure exerted by the engine oil on the internal components. This pressure is typically transmitted through a sensor, which converts the mechanical pressure into an electrical signal. This signal is then displayed on a gauge, allowing operators to monitor the oil pressure continuously. Proper oil pressure is crucial for lubricating engine parts, reducing friction, and maintaining optimal operating temperatures 2.

Purpose of the Cummins 3393003 Oil Pressure Gauge

The Cummins 3393003 Oil Pressure Gauge is specifically designed for use in Cummins engines found in commercial trucks. Its primary role is to provide accurate and reliable readings of the engine’s oil pressure. This information is vital for ensuring that the engine operates within safe parameters, preventing issues such as engine wear, overheating, and potential breakdowns 3.

Functionality and Importance in Truck Operations

In the context of truck operations, the Cummins 3393003 Oil Pressure Gauge plays a pivotal role. It allows mechanics and drivers to monitor the engine’s health in real-time, enabling them to take corrective actions before minor issues escalate into major problems. This proactive approach to maintenance can significantly reduce downtime and repair costs, ensuring that the fleet remains operational and efficient 4.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are essential for the optimal performance of this Cummins part. Here are some key practices:

-

Routine Inspections: Regularly inspect the gauge for any signs of wear or damage. Check the wiring and connections to ensure they are secure and free from corrosion.

-

Calibration: Periodically calibrate the gauge to maintain accuracy. This can be done using specialized equipment to ensure that the readings are precise.

-

Cleaning: Keep the gauge and its sensor clean. Oil and dirt buildup can affect the accuracy of the readings. Use appropriate solvents and tools to clean the components without causing damage.

-

Replacement: If the gauge shows inconsistent readings or fails to function correctly, it may need to be replaced. Using genuine Cummins parts ensures compatibility and reliability.

About Cummins

Cummins is a global power leader and a pioneer in the design and manufacture of engines, engine-related technology, and related services. With a reputation for quality and innovation, Cummins products are trusted by fleet operators worldwide. The company’s commitment to engineering excellence and customer satisfaction makes it a preferred choice for heavy-duty truck parts.

Conclusion

The Cummins 3393003 Oil Pressure Gauge is an indispensable tool for maintaining the health and performance of commercial trucks. By understanding its function, importance, and maintenance requirements, fleet operators and mechanics can ensure that their vehicles remain reliable and efficient. Proper use and care of this component contribute to the overall safety and longevity of the engine, supporting the critical operations of commercial trucking fleets.

-

Julian Happian-Smith, An Introduction to Modern Vehicle Design

↩ -

Moustafa ElGindy, Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics, Springer Nature Switzerland AG, 2023

↩ -

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Automotive Transmissions: Fundamentals, Selection, Design and Application, Springer-Verlag Berlin Heidelberg, 1994

↩ -

Cummins, Operation and Maintenance Manual, Bulletin Number 5677025, F2.5 CM2620 F150B

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.