This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3396007 Oil Seal is a component designed to ensure the efficient operation of commercial trucks. Its purpose is to maintain the integrity of the engine or transmission system by preventing lubricant leakage and contamination. This seal plays a role in the overall performance and longevity of truck machinery.

Basic Concepts of Oil Seals

An oil seal, also known as a rotary shaft seal, is a mechanical device used in machinery to prevent the leakage of lubricants and the ingress of contaminants. It operates by creating a barrier between rotating and stationary parts, ensuring that lubricants remain within the system while keeping out dirt, dust, and other particles that could cause damage or reduce efficiency 1.

Purpose of the 3396007 Oil Seal

The Cummins 3396007 Oil Seal is specifically designed to function within the engine or transmission of a truck. Its primary role is to maintain system integrity by sealing the interface between rotating shafts and stationary housings. This ensures that lubricants are retained within the system, providing necessary lubrication to moving parts and protecting them from wear and tear. Additionally, it prevents contaminants from entering the system, which could lead to increased friction, overheating, and potential failure of components 2.

Key Features

The Cummins 3396007 Oil Seal is constructed with precision to meet the demanding requirements of commercial truck applications. It is typically made from durable materials such as nitrile rubber or fluorocarbon elastomers, which offer excellent resistance to oils, fuels, and other chemicals. The seal features specific dimensions tailored to fit snugly within the engine or transmission, ensuring a secure and effective barrier. Unique characteristics may include reinforced edges to withstand high pressures and temperatures, as well as anti-rotation devices to maintain proper alignment during operation.

Benefits

Utilizing the Cummins 3396007 Oil Seal offers several advantages in truck operations. It contributes to improved efficiency by ensuring that lubricants are effectively contained and distributed within the system. This results in reduced friction and wear on moving parts, leading to enhanced performance and longevity of the engine or transmission. Additionally, the seal’s reliable design helps to maintain system integrity, reducing the risk of leaks and contamination, which can lead to costly repairs and downtime 3.

Installation Process

Proper installation of the Cummins 3396007 Oil Seal is crucial for its effective performance. The process involves several steps: first, ensuring the shaft and housing are clean and free of debris; second, lubricating the seal lips to facilitate smooth installation; third, using appropriate tools to press the seal into place without damaging it; and finally, verifying that the seal is correctly seated and aligned. Following these steps ensures that the seal will function as intended, providing a secure barrier against lubricant leakage and contamination.

Common Issues and Troubleshooting

Oil seals, including the Cummins 3396007, may encounter issues such as leaks, wear, or damage over time. Common problems can arise from improper installation, excessive wear on the shaft, or exposure to incompatible lubricants. Diagnosing issues typically involves inspecting the seal for signs of wear or damage, checking the condition of the shaft, and ensuring that the seal is correctly installed. Recommended troubleshooting steps include cleaning and re-lubricating the seal, replacing worn or damaged components, and verifying that the correct lubricants are being used.

Maintenance Tips

To prolong the life of the Cummins 3396007 Oil Seal, routine maintenance practices are recommended. This includes regular inspection intervals to check for signs of wear or damage, cleaning the seal and surrounding areas to remove contaminants, and ensuring that the correct lubricants are used. Additionally, it is important to monitor the condition of the shaft and housing, as any irregularities can affect the seal’s performance. When signs of significant wear or damage are observed, considering replacement of the seal is advisable to maintain system integrity and prevent potential failures.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of commercial applications. Cummins’ commitment to innovation and customer satisfaction has solidified its position as a trusted provider in the industry.

Cummins Oil Seal Part 3396007 Compatibility with Engine Models

The Cummins Oil Seal part number 3396007 is designed to ensure the integrity of various engine systems by preventing oil leaks. This seal is engineered to fit seamlessly within the engine architecture, providing a reliable barrier against oil seepage. Its application spans across several Cummins engine models, ensuring that it meets the stringent requirements of these high-performance engines.

G8.3 Engine Series

In the G8.3 engine series, the oil seal part 3396007 is integral to maintaining the engine’s operational efficiency. This seal is strategically placed to contain oil within the engine’s critical areas, such as the crankshaft and camshaft regions. Its design ensures that it can withstand the high temperatures and pressures inherent in these engines, thereby extending the service life of the engine components it protects.

Grouped Engine Models

The Cummins Oil Seal part 3396007 is not limited to a single engine model but is compatible with a range of engines within the G8.3 series. This compatibility is due to the seal’s standardized dimensions and material properties, which are tailored to fit various engine configurations. The seal’s ability to adapt to different engine designs underscores its versatility and importance in the maintenance and longevity of these engines.

The seal’s application in these engines is crucial for preventing oil contamination and ensuring that the engine operates at peak performance. Its role in maintaining the engine’s internal pressure and preventing oil leaks is vital for the overall health and efficiency of the engine.

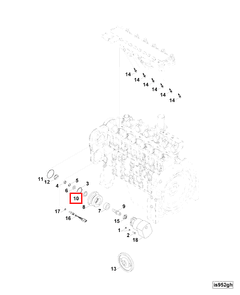

Role of Part 3396007 Oil Seal in Engine Systems

The Part 3396007 Oil Seal is integral to maintaining the efficiency and reliability of various engine components. In the accessory drive arrangement, this oil seal prevents lubricant leakage, ensuring that the accessory drive components, such as the alternator, power steering pump, and air conditioning compressor, receive consistent lubrication. This consistent lubrication reduces wear and tear, enhancing the longevity and performance of these accessories.

Within the ignition system, the oil seal plays a significant role by safeguarding the ignition components from contaminants. By preventing oil from seeping into the ignition system, it ensures that the spark plugs and ignition coils operate in a clean environment. This protection is essential for maintaining the precision and reliability of the ignition timing, which is vital for engine performance and fuel efficiency.

Additionally, the oil seal contributes to the overall system integrity by maintaining proper lubrication levels in moving parts while preventing oil from contaminating other engine areas. This balance is necessary for the smooth operation of the engine, reducing the risk of component failure and enhancing the engine’s durability.

Conclusion

The Cummins 3396007 Oil Seal is a critical component in the maintenance and efficiency of commercial truck engines. Its role in preventing lubricant leakage and contamination ensures the longevity and performance of engine components. Proper installation, regular maintenance, and timely replacement are essential practices to maximize the benefits of this part. Cummins’ commitment to quality and innovation continues to provide reliable solutions for the commercial truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.