This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

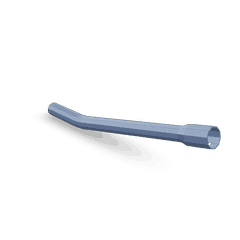

The Cummins Oil Pressure Gauge Tube, identified by part number 3400567, is a component designed to facilitate the monitoring of oil pressure within heavy-duty trucks. Cummins, a well-established name in the automotive and heavy-duty truck industries, produces this gauge tube to ensure the efficient operation and longevity of truck engines. The gauge tube is integral to maintaining optimal engine performance by providing accurate oil pressure readings, which are vital for engine health and operational efficiency 1.

Basic Concepts of Oil Pressure Gauge Tubes

An Oil Pressure Gauge Tube is a component that conveys oil pressure readings from the engine to the gauge on the vehicle’s dashboard. It operates by connecting to the engine’s oil pressure sensor and transferring the pressure data to the gauge. This allows drivers and mechanics to monitor the engine’s oil pressure in real-time, ensuring that it remains within the manufacturer’s specified range. Accurate oil pressure readings are essential for diagnosing potential engine issues and maintaining engine health 2.

Purpose of the 3400567 Oil Pressure Gauge Tube

The 3400567 Oil Pressure Gauge Tube plays a role in the operation of a truck by facilitating the accurate transmission of oil pressure data from the engine to the dashboard gauge. This component contributes to engine monitoring and maintenance by allowing for the early detection of oil pressure anomalies, which can indicate issues such as oil pump failure, clogged oil filters, or worn engine bearings. Regular monitoring of oil pressure helps in preventing engine damage and ensures the engine operates within safe parameters 3.

Key Features

The 3400567 Oil Pressure Gauge Tube is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in harsh operating environments. The design of the tube includes precise fittings that ensure a secure connection to both the engine and the gauge, minimizing the risk of leaks. Additionally, the tube is engineered to withstand high pressure and temperature variations, maintaining accuracy and reliability over time.

Benefits

Utilizing the 3400567 Oil Pressure Gauge Tube offers several benefits. It contributes to improved engine performance by enabling accurate oil pressure monitoring, which is vital for maintaining engine health. The tube’s durable construction and precise design enhance its longevity, reducing the need for frequent replacements. Reliable oil pressure monitoring facilitated by this component aids in the early detection of engine issues, potentially saving on repair costs and extending the engine’s lifespan.

Installation Process

Installing the 3400567 Oil Pressure Gauge Tube requires careful attention to detail to ensure proper function and safety. The process involves disconnecting the old gauge tube, if present, and connecting the new tube to the engine’s oil pressure sensor and the dashboard gauge. Tools required may include wrenches for securing connections and a pressure tester to verify the system’s integrity post-installation. Safety precautions include ensuring the engine is cool before beginning work and following manufacturer guidelines to prevent damage to the engine or gauge system.

Troubleshooting Common Issues

Common issues with the 3400567 Oil Pressure Gauge Tube may include inaccurate readings, leaks, or connection failures. Troubleshooting steps involve checking the connections for tightness and integrity, inspecting the tube for signs of wear or damage, and verifying the gauge’s calibration. Solutions may range from tightening connections to replacing the tube if it is damaged. Regular inspections and maintenance can help prevent many of these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the 3400567 Oil Pressure Gauge Tube, routine maintenance practices are recommended. This includes regular inspections for signs of wear, corrosion, or leaks, and cleaning the connections to prevent buildup that could affect readings. Inspection intervals should align with the vehicle’s maintenance schedule, and any issues identified during inspections should be addressed promptly to maintain accurate oil pressure monitoring.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation within the automotive and heavy-duty truck industries. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial vehicles and industrial applications. Cummins’ commitment to excellence and customer satisfaction has solidified its position as a trusted name in the industry.

Cummins Oil Pressure Gauge Tube (Part 3400567) Compatibility

The Cummins Oil Pressure Gauge Tube, identified by part number 3400567, is a critical component in the engine’s lubrication system. This part is designed to provide accurate oil pressure readings, ensuring the engine operates within safe parameters. Below is a detailed description of how this part fits with various Cummins engines.

M11 CELECT PLUS and M11 MECHANICAL Engines

The Oil Pressure Gauge Tube (3400567) is compatible with both the M11 CELECT PLUS and M11 MECHANICAL engines. In these engines, the tube is typically mounted on the engine block, providing a direct connection to the oil system. This placement allows for precise monitoring of oil pressure, which is essential for maintaining engine health and performance. The tube interfaces with the engine’s oil pressure sensor, ensuring that the gauge on the dashboard accurately reflects the engine’s oil pressure status.

QSM11 CM570 Engine

For the QSM11 CM570 engine, the Oil Pressure Gauge Tube (3400567) is similarly integrated into the engine’s design. This engine, known for its robust performance, relies on the accurate measurement of oil pressure to prevent engine damage. The tube is installed in a manner that ensures it is protected from extreme temperatures and vibrations, maintaining its integrity and functionality over time. The connection point for the oil pressure sensor is strategically placed to provide reliable and consistent readings.

Installation and Maintenance

Proper installation of the Oil Pressure Gauge Tube (3400567) is crucial for its effective operation. Technicians should ensure that the tube is securely fastened and free from any obstructions or damage. Regular maintenance checks should include verifying the tube’s condition and ensuring that it is properly aligned with the oil pressure sensor. Any signs of wear or damage should be addressed promptly to prevent potential engine issues.

Compatibility Summary

- M11 CELECT PLUS

- M11 MECHANICAL

- QSM11 CM570

The Oil Pressure Gauge Tube (3400567) is a versatile component that fits seamlessly into the specified Cummins engines, providing essential oil pressure monitoring capabilities.

Role of Part 3400567 Oil Pressure Gauge Tube in Engine Systems

The Part 3400567 Oil Pressure Gauge Tube is an essential component in the arrangement of various engine systems, ensuring accurate and reliable monitoring of oil pressure. This component interfaces with several key elements within the engine, including the oil fill system, the gauge, and the oil level sensor.

Integration with Oil Fill System

In the oil fill system, the Oil Pressure Gauge Tube is positioned to channel oil from the engine’s oil passages to the gauge. This setup allows for consistent oil flow, which is necessary for the gauge to provide accurate readings. The tube’s precise placement ensures that it captures the oil pressure at a representative point within the engine, offering a true reflection of the oil’s performance under various operating conditions.

Connection to the Gauge

The gauge relies on the Oil Pressure Gauge Tube to transmit oil pressure data. The tube acts as a direct conduit, transferring the pressure from the engine’s oil passages to the gauge’s sensing element. This direct connection minimizes the risk of pressure loss or distortion, ensuring that the gauge displays real-time, accurate oil pressure readings. Engineers and mechanics can thus rely on these readings to make informed decisions about engine health and performance.

Interaction with Oil Level Sensor

While the primary function of the Oil Pressure Gauge Tube is to monitor pressure, its installation can also influence the oil level sensor. Proper arrangement of the tube ensures that it does not interfere with the oil level sensor’s operation. This careful coordination is vital for maintaining the overall integrity of the engine’s lubrication system, as both pressure and level readings are necessary for comprehensive engine monitoring.

Overall System Harmony

The Oil Pressure Gauge Tube’s role extends beyond individual components; it contributes to the harmonious operation of the entire engine system. By providing accurate pressure data, it aids in the early detection of potential issues, such as oil pump failures or blockages in the oil passages. This proactive monitoring capability is invaluable for maintaining engine efficiency and longevity.

Conclusion

In summary, the Part 3400567 Oil Pressure Gauge Tube is a pivotal element in the engine’s lubrication system, facilitating precise oil pressure monitoring and contributing to the overall reliability and performance of the engine. Its integration with the oil fill system, connection to the gauge, and interaction with the oil level sensor ensure comprehensive engine monitoring. Regular maintenance and proper installation are crucial for the effective operation of this component, ultimately supporting the longevity and efficiency of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.