This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3401186 Lubricating Oil Pump is a component designed to facilitate the circulation of lubricating oil within the engine of commercial trucks. Its purpose is to ensure that all moving parts within the engine receive adequate lubrication, which is vital for reducing friction, wear, and heat generation. The significance of this pump lies in its contribution to the overall efficiency, performance, and longevity of the engine 1.

Basic Concepts of Lubricating Oil Pumps

A lubricating oil pump is a device that circulates oil throughout an engine to lubricate various components. Its function is to draw oil from the sump or oil pan and deliver it under pressure to critical engine parts such as bearings, pistons, and camshafts. The principles of operation typically involve a rotor or gear mechanism that creates a vacuum to pull oil in and then pressurizes it for distribution through the engine’s lubrication system 2.

Role of the 3401186 Lubricating Oil Pump in Truck Operation

The 3401186 Lubricating Oil Pump plays a specific role in the operation of a commercial truck by ensuring consistent and reliable lubrication of engine components. This pump helps maintain optimal engine performance by reducing friction between moving parts, which in turn minimizes wear and tear. Additionally, effective lubrication aids in heat dissipation, contributing to the engine’s longevity and overall efficiency 3.

Key Features of the 3401186 Lubricating Oil Pump

The design and construction of the 3401186 Lubricating Oil Pump incorporate several notable features. It is built using high-quality materials to withstand the demanding conditions within a commercial truck engine. The pump’s construction ensures durability and reliability, with precision-engineered components that facilitate efficient oil circulation. Unique characteristics may include advanced sealing technologies to prevent leaks and a robust rotor design for consistent performance.

Benefits of Using the 3401186 Lubricating Oil Pump

Utilizing the 3401186 Lubricating Oil Pump offers several advantages. Improved engine lubrication leads to reduced friction and wear on engine components, enhancing the engine’s durability. Additionally, efficient lubrication can contribute to better fuel efficiency by ensuring that the engine operates smoothly. The pump’s reliable performance also helps in maintaining the engine’s overall health, potentially reducing the need for frequent repairs.

Installation and Integration

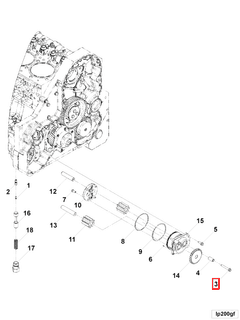

Proper installation of the 3401186 Lubricating Oil Pump within a truck’s engine system is crucial for its effective operation. Guidelines for installation include ensuring that the pump is correctly aligned with the engine’s lubrication system and that all connections are secure. It is also important to verify that the pump is compatible with the specific engine model to ensure optimal performance. Prerequisites may involve checking the engine’s oil level and ensuring that the lubrication system is free of contaminants.

Maintenance and Troubleshooting

Routine maintenance practices for the 3401186 Lubricating Oil Pump are vital for ensuring its optimal performance and longevity. Regular inspections should be conducted to check for signs of wear or damage. It is also important to monitor the pump’s operation for any unusual noises or vibrations, which may indicate potential issues. Troubleshooting tips include verifying the pump’s alignment, checking for proper oil levels, and ensuring that the lubrication system is clean and free of debris.

Common Issues and Solutions

Common problems that may arise with the 3401186 Lubricating Oil Pump include oil leaks, insufficient oil pressure, and pump failure. Solutions to these issues may involve inspecting and replacing worn seals, ensuring proper pump alignment, and conducting regular maintenance to prevent buildup of contaminants within the lubrication system. Preventive measures include using high-quality oil and filters, as well as adhering to recommended maintenance schedules.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer with a rich history in the commercial truck industry. The company offers a wide range of products, including engines, filtration systems, and power generation equipment. Cummins is renowned for its commitment to quality, innovation, and customer satisfaction, making it a trusted name in the industry. The company’s extensive product range and reputation for reliability underscore its position as a leader in the commercial truck sector.

Compatibility with Cummins Engines

The Cummins part number 3401186, a Lubricating Oil Pump, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the proper lubrication within the engine, ensuring smooth operation and longevity. Here is a breakdown of the engines that are compatible with this oil pump:

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM11 CM876 SN

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

QSM11 Series Engines

- QSM11 CM570

- QSM11 CM876

Each of these engines, whether part of the ISM, L10, M11, or QSM11 series, relies on the 3401186 oil pump to deliver the necessary lubrication for optimal operation. This part is a critical component in ensuring that these engines run smoothly and efficiently.

Role of Part 3401186 Lubricating Oil Pump in Engine Systems

The lubricating oil pump, identified by part number 3401186, is integral to the efficient operation of various engine systems. Its primary function is to circulate lubricating oil throughout the engine, ensuring that all moving parts are adequately coated to minimize friction and wear.

Integration with Engine Components

-

Crankshaft and Connecting Rods: The pump delivers oil to the crankshaft and connecting rods, which are subject to high levels of stress and friction. Consistent lubrication here is essential for smooth operation and longevity of these components.

-

Camshaft and Valve Train: In overhead cam engines, the pump ensures that the camshaft and valve train components receive a steady supply of oil. This lubrication is vital for the precise movement of the valves and the reduction of wear on the cam lobes.

-

Pistons and Cylinder Walls: Adequate lubrication between the pistons and cylinder walls is necessary to prevent seizing and to maintain compression efficiency. The pump plays a key role in maintaining this lubrication.

-

Bearings: Main and rod bearings rely on a continuous supply of oil to function correctly. The pump ensures that these bearings remain lubricated, which is essential for the rotational movement of the crankshaft and connecting rods.

-

Timing Chain or Belt: In engines equipped with a timing chain or belt, the pump provides lubrication to reduce friction and wear. This is particularly important in high-performance engines where timing components are under greater stress.

-

Oil Filter: The pump works in conjunction with the oil filter to ensure that the oil circulating through the engine is clean and free from contaminants. This partnership is essential for maintaining the integrity of the lubrication system.

-

Oil Cooler: In systems where an oil cooler is present, the pump facilitates the flow of oil through the cooler, helping to maintain optimal oil temperature. This is especially important in high-performance or high-stress applications.

-

Turbocharger (if equipped): In turbocharged engines, the pump ensures that the turbocharger bearings and other moving parts receive adequate lubrication. This is vital for the turbocharger’s performance and durability.

By effectively circulating lubricating oil, part 3401186 ensures that all these components operate within their designed parameters, contributing to the overall efficiency, performance, and reliability of the engine.

Conclusion

The Cummins 3401186 Lubricating Oil Pump is a critical component in the maintenance and operation of commercial truck engines. Its role in ensuring proper lubrication of engine components contributes significantly to the engine’s efficiency, performance, and longevity. Proper installation, regular maintenance, and timely troubleshooting are essential practices to maximize the benefits of this part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.