Introduction

The Cummins 3401431 Oil Gauge Tube is a critical component designed to facilitate the accurate measurement of oil levels within commercial truck engines. This part ensures the engine operates efficiently and reliably by providing precise oil level readings, contributing to the overall maintenance and performance of the vehicle 1.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube allows for the measurement of oil levels within an engine by connecting to the oil reservoir and providing a pathway for oil to travel to the gauge. This measurement is vital for monitoring the engine’s lubrication system, ensuring that there is sufficient oil to prevent damage from friction and wear 2.

Purpose of the 3401431 Oil Gauge Tube

This Cummins part plays a role in the operation of a truck by accurately measuring oil levels, which is fundamental for maintaining optimal engine performance. It ensures that the engine receives the necessary lubrication to operate smoothly, thereby contributing to the longevity and efficiency of the engine 3.

Key Features

The 3401431 is characterized by its robust design and the materials used in its construction, which are chosen for their durability and resistance to the harsh conditions within an engine. Its design allows for precise oil level measurement, and it may include features such as a secure fitting mechanism to ensure a tight seal and prevent leaks.

Benefits

Utilizing this part can lead to improved engine reliability through consistent and accurate oil level monitoring. This, in turn, can enhance performance monitoring capabilities, allowing for timely maintenance and potentially reducing the risk of engine damage. Additionally, better maintenance practices informed by accurate oil level readings can result in cost savings over time.

Installation Process

Installing the 3401431 requires careful attention to ensure proper fitting and function. The process involves securing the tube to the oil reservoir, ensuring a tight seal to prevent leaks, and connecting it to the gauge. Tools required may include wrenches and sealant, and it is important to follow manufacturer guidelines to ensure correct installation.

Troubleshooting Common Issues

Common problems associated with oil gauge tubes include inaccurate readings and leaks. Inaccurate readings may be addressed by checking the tube for blockages or damage and ensuring it is correctly installed. Leaks can often be resolved by tightening connections or replacing damaged components.

Maintenance Tips

Regular maintenance of the 3401431 is recommended to ensure its longevity and accurate performance. This includes periodic cleaning to remove any buildup that may affect readings, inspection for signs of wear or damage, and replacement according to manufacturer guidelines or when performance issues arise.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the 3401431 Oil Gauge Tube.

Role of Part 3401431 Oil Gauge Tube in Engine Systems

This part is an integral component in the accurate measurement and monitoring of oil levels within an engine system. It interfaces with several key components to ensure the engine operates efficiently and safely.

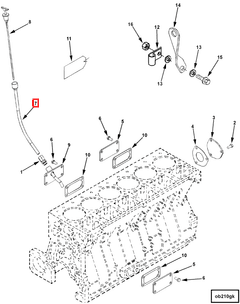

Interaction with Cylinder Block Cover

The Oil Gauge Tube is typically mounted on the cylinder block cover, which houses the engine’s internal components. This positioning allows the tube to directly access the oil within the sump, providing a clear path for the oil level to be measured. The tube’s connection to the cover ensures a sealed environment, preventing oil leaks and maintaining the integrity of the oil system.

Integration with Oil Fill Arrangement

In conjunction with the oil fill arrangement, the Oil Gauge Tube plays a significant role in maintaining the correct oil level. The oil fill arrangement, which includes the oil filler cap and associated passages, allows for the addition of oil to the system. The Oil Gauge Tube provides feedback on the current oil level, enabling technicians to add the appropriate amount of oil during maintenance procedures. This ensures that the engine is neither overfilled nor underfilled, both of which can lead to performance issues and potential damage.

Functionality with Oil Level Gauge

The Oil Gauge Tube works in tandem with the oil level gauge to provide a visual or electronic indication of the oil level to the operator. The tube extends into the oil sump, and as the oil level changes, the gauge reflects these variations. This real-time monitoring is essential for the early detection of oil leaks or consumption, allowing for timely interventions to prevent engine damage. The accurate reading provided by the Oil Gauge Tube ensures that the oil level gauge delivers reliable data, contributing to the overall maintenance and longevity of the engine.

Conclusion

The Cummins 3401431 Oil Gauge Tube is a vital component in the maintenance and operation of commercial truck engines. By ensuring accurate oil level measurements, it contributes to the engine’s efficiency, reliability, and longevity. Regular maintenance and proper installation of this part are essential for optimal engine performance and to prevent potential damage due to incorrect oil levels.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.