This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3406582 Lubricating Oil Pump is a critical component in the operation of commercial trucks. Cummins, a renowned name in the automotive industry, is known for its high-quality engine components. This part is designed to ensure the efficient lubrication of engine parts, which is fundamental for the smooth operation and longevity of commercial trucks 1.

Basic Concepts of Lubricating Oil Pumps

A lubricating oil pump is an integral part of an engine system, responsible for circulating oil to various engine components. Its primary functions include reducing friction between moving parts, cooling the engine, cleaning internal components, and sealing combustion chambers 2. Proper lubrication is essential for minimizing wear and tear, ensuring that engine parts operate smoothly and efficiently.

Purpose of the 3406582 Lubricating Oil Pump

The 3406582 Lubricating Oil Pump plays a significant role in the operation of a truck by ensuring that engine components receive adequate lubrication. This pump helps maintain optimal engine performance by delivering oil to critical areas such as bearings, pistons, and cylinders. Effective lubrication enhances engine efficiency, reduces the risk of overheating, and contributes to the overall longevity of the engine 3.

Key Features

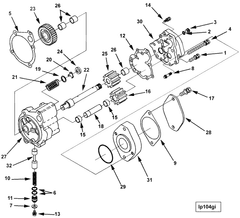

The 3406582 Lubricating Oil Pump is distinguished by its robust design and the use of high-quality materials. It features a durable construction that can withstand the demanding conditions of commercial truck engines. The pump is engineered to provide consistent oil flow, ensuring that all engine components are properly lubricated. Additionally, it includes precision-machined parts that enhance its reliability and performance 4.

Benefits

Using the 3406582 Lubricating Oil Pump offers several advantages. It contributes to improved engine efficiency by ensuring that all moving parts are adequately lubricated. This reduces friction and wear, leading to lower maintenance costs over time. The pump’s reliable performance also enhances the overall reliability of the engine, providing truck operators with peace of mind.

Installation Process

Installing the 3406582 Lubricating Oil Pump involves several steps. Begin by ensuring that the engine is clean and free of debris. Use the appropriate tools to remove the old pump, taking care to note the orientation of any connected hoses or wires. Install the new pump in the reverse order, ensuring that all connections are secure. Finally, perform a system check to confirm that the pump is functioning correctly.

Troubleshooting

Common issues with the 3406582 Lubricating Oil Pump may include inadequate oil pressure, leaks, or unusual noises. To troubleshoot these problems, first, check the oil level and ensure that it is within the recommended range. Inspect all connections for leaks and tighten any loose fittings. If the pump is making unusual noises, it may indicate a problem with the internal components, and professional inspection may be necessary.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the 3406582 Lubricating Oil Pump. Inspect the pump and its connections at regular intervals, cleaning any debris or buildup. Replace any worn or damaged parts as needed. Additionally, follow the manufacturer’s recommendations for oil changes to ensure that the pump continues to operate efficiently.

Performance Enhancements

The 3406582 Lubricating Oil Pump contributes to overall engine performance by providing consistent and reliable lubrication. While the pump is designed for optimal performance, certain upgrades or modifications can further enhance its functionality. These may include using higher viscosity oil for added protection or installing additional filtration systems to ensure cleaner oil flow.

About Cummins

Cummins Inc. is a global leader in the design, manufacture, and distribution of engines and related technologies. With a rich history dating back to 1919, Cummins has built a reputation for innovation and quality in the commercial truck industry. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial vehicle operators. Cummins’ commitment to quality and innovation ensures that their components, like the 3406582 Lubricating Oil Pump, deliver reliable performance and durability.

Compatibility with Cummins Engines

The 3406582 lubricating oil pump is compatible with several Cummins engine models, including:

-

N14 Celect Plus: This engine is known for its robust design and high performance, making it suitable for heavy-duty applications. The 3406582 oil pump ensures that the N14 Celect Plus engine maintains optimal lubrication, contributing to its durability and efficiency.

-

Other Cummins Engines: While the primary focus here is on the N14 Celect Plus, the 3406582 oil pump is also designed to fit other Cummins engines within the same engine family. This compatibility ensures that users can maintain their engines with a standardized part, simplifying maintenance and repair processes.

Installation and Functionality

The installation of the 3406582 oil pump is straightforward, designed to fit precisely within the engine’s architecture. It is engineered to deliver the necessary oil flow to all critical engine components, ensuring that the engine operates smoothly and efficiently. The pump’s design allows for easy integration with the engine’s existing lubrication system, minimizing downtime and maintenance costs.

Importance of Proper Lubrication

Proper lubrication is essential for the longevity and performance of any engine. The 3406582 oil pump plays a pivotal role in this by ensuring that all moving parts are adequately lubricated. This reduces friction, prevents overheating, and minimizes wear and tear, ultimately extending the engine’s lifespan and maintaining its performance over time 5.

Conclusion

By using the Cummins 3406582 lubricating oil pump, engine operators can be confident that their engines are receiving the high-quality lubrication they need to operate efficiently and reliably. This part ensures that all critical engine components are adequately lubricated, contributing to the overall health and performance of the engine system.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ -

Caines, Arthur J, Roger F Haycock, and John E Hillier. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Caines, Arthur J, Roger F Haycock, and John E Hillier. Automotive Lubricants Reference Book. SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.