This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

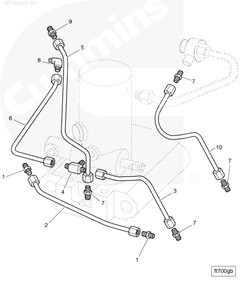

The Lubricating Oil Supply Tube, identified by Part #3422830, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This tube is integral to the lubrication system of heavy-duty truck engines, ensuring that oil is efficiently distributed to critical engine components 1.

Function and Operation

The Lubricating Oil Supply Tube operates as a conduit within the engine’s lubrication system. Its primary role is to deliver oil from the oil pump to various engine components that require lubrication. This includes bearings, pistons, and other moving parts. By maintaining a consistent flow of oil, the tube helps in reducing friction and wear, which are essential for the smooth operation of the engine 2.

Purpose of the Lubricating Oil Supply Tube

The Lubricating Oil Supply Tube plays a significant role in the operation of a truck by ensuring that engine components receive the necessary lubrication. This contributes to the overall performance and longevity of the engine. Proper lubrication is vital for minimizing wear on engine parts, which in turn helps in maintaining engine efficiency and reliability over time 3.

Key Features

The Lubricating Oil Supply Tube is designed with several key features that enhance its functionality. It is typically made from durable materials that can withstand the high temperatures and pressures within an engine. The design of the tube may include specific fittings and connections that ensure a secure and leak-free installation. Additionally, the tube’s dimensions and flow characteristics are engineered to meet the lubrication demands of the engine it serves 4.

Benefits

The use of the Lubricating Oil Supply Tube offers several advantages. It ensures improved engine lubrication, which is fundamental for the efficient operation of engine components. This consistent lubrication helps in reducing wear on these parts, leading to enhanced engine longevity. Furthermore, by maintaining optimal lubrication, the tube contributes to the overall efficiency of the engine, potentially improving fuel economy and performance 5.

Installation and Compatibility

Proper installation of the Lubricating Oil Supply Tube is important for ensuring its effectiveness and the overall health of the engine. Installation procedures may vary depending on the specific engine model, and it is important to follow manufacturer guidelines to ensure compatibility and proper function. Considerations such as correct alignment, secure connections, and the use of appropriate seals or gaskets are important during installation 6.

Maintenance and Troubleshooting

Routine maintenance of the Lubricating Oil Supply Tube is important for its longevity and the efficient operation of the engine. This may include regular inspections for signs of wear, leaks, or blockages. Troubleshooting common issues, such as leaks or reduced oil flow, may involve checking connections, replacing seals, or cleaning the tube to remove any obstructions. Adhering to a maintenance schedule can help in identifying and addressing potential issues before they lead to more significant problems 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to manufacturing high-quality components is evident in its extensive range of products, which are designed to meet the demanding requirements of various applications 8.

Cummins Engine Compatibility with Lubricating Oil Supply Tube Part 3422830

The Cummins part 3422830, a Lubricating Oil Supply Tube, is designed to fit seamlessly within a range of Cummins engines, ensuring optimal lubrication and engine performance. This part is engineered to meet the specific needs of the following engines:

QSW/QSV82 and QSW27 Engines

The QSW/QSV82 and QSW27 engines are part of Cummins’ range of medium-duty diesel engines. These engines are known for their durability and efficiency, often used in various applications such as trucks, buses, and industrial machinery. The lubricating oil supply tube part 3422830 is crucial for these engines as it ensures that the oil is properly distributed to the engine components, maintaining the necessary lubrication levels and preventing wear and tear 9.

QSW36 and QSW73 Engines

The QSW36 and QSW73 engines are also medium-duty diesel engines from Cummins, designed for heavy-duty applications. These engines are typically found in construction equipment, agricultural machinery, and other heavy-duty vehicles. The lubricating oil supply tube part 3422830 is integral to these engines, providing a reliable pathway for oil to reach critical engine parts, ensuring smooth operation and longevity 10.

Grouping by Application

When considering the application of the lubricating oil supply tube part 3422830, it is essential to recognize that these engines are often used in demanding environments. The part’s design ensures that it can withstand the rigors of these conditions, providing consistent and reliable performance. Whether in the transportation sector or industrial machinery, this part plays a vital role in maintaining engine health and efficiency 11.

Role of Part 3422830 Lubricating Oil Supply Tube in Engine Systems

The lubricating oil supply tube, identified as part 3422830, is integral to the efficient operation of various engine systems. This component ensures a consistent and reliable flow of lubricating oil to critical engine parts, enhancing performance and longevity 12.

Integration with Fuel Assembly Plumbing

In engines where the fuel assembly plumbing is complex, the lubricating oil supply tube works in tandem to maintain optimal conditions. It delivers oil to bearings and moving parts within the fuel assembly, reducing friction and wear. This synergy ensures that the fuel assembly operates smoothly, contributing to the overall efficiency of the engine 13.

Coordination with Fuel Plumbing

The fuel plumbing system relies on precise lubrication to function effectively. Part 3422830 ensures that components within the fuel plumbing, such as pumps and valves, receive adequate lubrication. This prevents undue stress on these parts, promoting consistent fuel delivery and combustion 14.

General Plumbing Systems

In broader plumbing systems within the engine, the lubricating oil supply tube plays a supportive role. It facilitates the lubrication of various mechanical components, from small fittings to larger conduits. This lubrication is essential for preventing leaks, reducing maintenance needs, and ensuring the plumbing system’s durability 15.

Fuel System Lubrication

Specifically within the fuel system, the lubricating oil supply tube is vital for lubricating critical pathways and components. This includes fuel lines, injectors, and filters. Proper lubrication in these areas ensures that fuel is delivered efficiently and that the system remains free from contaminants that could impede performance 16.

Plumbing Fuel Assembly

The plumbing fuel assembly is a comprehensive system that benefits significantly from the lubricating oil supply tube. By ensuring all moving parts within this assembly are well-lubricated, part 3422830 helps maintain the integrity and performance of the fuel delivery system. This results in better engine responsiveness and fuel economy 17.

Conclusion

In summary, the Lubricating Oil Supply Tube (Part #3422830) is a key component in maintaining the health and efficiency of various engine systems, particularly those involving fuel delivery and plumbing. Its role in providing consistent lubrication to critical parts ensures that these systems operate smoothly and reliably, contributing to the overall performance and longevity of the engine 18.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Cummins Inc. (n.d.). Service Manual (5411104).

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Cummins Inc. (n.d.). Service Manual (5411104).

↩ -

Cummins Inc. (n.d.). Service Manual (5411104).

↩ -

Cummins Inc. (n.d.). Service Manual (5411104).

↩ -

Cummins Inc. (n.d.). Service Manual (5411104).

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Cummins Inc. (n.d.). Service Manual (5411104).

↩ -

Cummins Inc. (n.d.). Service Manual (5411104).

↩ -

Cummins Inc. (n.d.). Service Manual (5411104).

↩ -

Cummins Inc. (n.d.). Service Manual (5411104).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.