This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

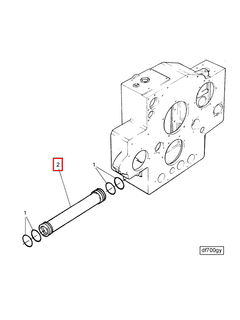

The Lubricating Oil Transfer Tube (Part #3423426) by Cummins is a component designed to facilitate the efficient transfer of lubricating oil within the engine system of commercial trucks. This part plays a significant role in ensuring that various engine components receive the necessary lubrication to operate smoothly and efficiently. Its proper function is integral to maintaining engine performance and longevity.

Function and Operation

The Lubricating Oil Transfer Tube functions as a conduit within the lubrication system of a truck engine. It is responsible for transferring lubricating oil from the oil pump to different engine components, such as bearings, pistons, and other moving parts. By ensuring a consistent flow of oil, the tube helps to reduce friction and wear on these components, which is vital for the engine’s overall efficiency and durability 1.

Key Features

The Lubricating Oil Transfer Tube is constructed from high-quality materials that offer resistance to corrosion and wear. Its design includes precise fittings and connections to ensure a secure and leak-free installation. The tube’s robust construction and durable materials contribute to its ability to withstand the high pressures and temperatures within the engine environment. Additionally, the tube may feature specific design elements that enhance its performance, such as reinforced sections to prevent kinking or blockages 2.

Benefits

The use of the Lubricating Oil Transfer Tube provides several advantages. It enhances lubrication efficiency by ensuring that oil is delivered consistently and under the right pressure to all necessary engine components. This consistent lubrication reduces friction and wear, which can lead to improved engine performance and extended component lifespan. Furthermore, the tube’s design and material composition contribute to its durability, reducing the need for frequent replacements and maintenance 3.

Installation and Compatibility

Proper installation of the Lubricating Oil Transfer Tube is crucial for its effective operation. Installation procedures should follow manufacturer guidelines to ensure a secure fit and proper alignment with the engine’s lubrication system. The tube is designed to be compatible with Cummins engines, ensuring seamless integration and optimal performance. It is also important to consider the specific requirements of the truck model to ensure compatibility and proper function.

Maintenance and Troubleshooting

To maintain the Lubricating Oil Transfer Tube’s performance, regular inspections and maintenance are recommended. This includes checking for signs of wear, leaks, or blockages that could affect oil flow. Common issues may include oil leaks at connections or reduced oil pressure, which can often be addressed by tightening connections or cleaning the tube. In cases of significant damage or wear, replacement may be necessary to ensure continued efficient operation.

Safety Considerations

When working with the Lubricating Oil Transfer Tube, it is important to follow safety precautions to prevent injury and ensure proper handling. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, when inspecting or maintaining the tube. Additionally, ensuring that the engine is cool and the oil system is depressurized before beginning any work can help prevent accidents. Regular inspections for wear or damage are also crucial to identify potential issues before they lead to more significant problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality is evident in its product offerings, which are designed to meet the demanding requirements of commercial applications. Cummins’ focus on innovation ensures that its components, like the Lubricating Oil Transfer Tube, are at the forefront of technology and performance in the industry.

Compatibility with Cummins Engines

The Lubricating Oil Transfer Tube part number 3423426 is designed to fit seamlessly within several Cummins engine models. This part is essential for maintaining the proper lubrication within the engine, ensuring that all moving parts are adequately lubricated to prevent wear and tear.

QSV81G and QSW27 Engines

The 3423426 oil transfer tube is compatible with both the QSV81G and QSW27 engines. These engines, while differing in some specifications, share a similar design in their lubrication systems, allowing this part to fit effectively in both models. The tube’s design ensures that oil is transferred from the oil reservoir to the engine’s critical components, maintaining optimal lubrication levels.

QSW36 Engine

Similarly, the QSW36 engine also accommodates the 3423426 oil transfer tube. This engine model, like the QSV81G and QSW27, relies on this part to ensure that the lubrication system operates efficiently. The tube’s placement and design are engineered to integrate smoothly with the QSW36’s lubrication requirements, providing a reliable solution for maintaining engine health.

Role in Engine Systems

The Lubricating Oil Transfer Tube is an integral component in the efficient operation of various engine systems. It facilitates the seamless transfer of lubricating oil between different engine components, ensuring optimal performance and longevity.

In the Assembly Housing Gear and Camshaft Drive systems, the oil transfer tube ensures that the gears and camshafts receive a consistent supply of lubricating oil. This reduces friction and wear, allowing these components to operate smoothly and efficiently.

For the L8+V16 Assy and CCW Camshaft, the tube plays a significant role in maintaining the proper lubrication levels. This is particularly important in high-performance engines where the camshaft and associated components experience substantial stress and heat.

In the Front Gear Train Accessory, the oil transfer tube ensures that the accessory components, which often include tensioners and idlers, remain well-lubricated. This is essential for the reliable operation of the gear train and the overall engine timing system.

The Heat Exchanger and Gear Assembly Housing also benefit from the consistent oil flow provided by the transfer tube. Effective lubrication in these areas helps dissipate heat and prevent overheating, which can lead to component failure.

Furthermore, in the Oil Transfer Assembly Tube and Heat Assembly Exchanger, the tube ensures that the oil circulates efficiently through the heat exchanger, aiding in the regulation of engine temperature. This is vital for maintaining engine efficiency and preventing thermal stress on engine components.

Conclusion

The Lubricating Oil Transfer Tube (Part #3423426) by Cummins is a critical component in the lubrication system of commercial truck engines. Its role in ensuring consistent oil flow to various engine components contributes to reduced friction, wear, and improved engine performance. Proper installation, maintenance, and adherence to safety precautions are essential for maximizing the benefits of this part. With its compatibility across several Cummins engine models, the 3423426 oil transfer tube stands as a testament to Cummins’ commitment to quality and innovation in the commercial truck industry.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.