This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Supply Tube 3430121, manufactured by Cummins, is a critical component in the engine lubrication system of heavy-duty trucks. This part facilitates the delivery of oil to various engine components, ensuring efficient operation and longevity of the engine by reducing friction, wear, and heat generation 4.

Function and Operation

This Cummins part operates as a conduit within the engine’s lubrication system. Its primary function is to deliver oil from the oil pump to critical engine components such as bearings, pistons, and other moving parts. This ensures a consistent supply of lubricant, which is necessary for their smooth operation and protection against wear and tear 3.

Key Features

The Lubricating Oil Supply Tube 3430121 is designed with specific characteristics that enhance its performance and durability. It is constructed from high-quality materials that can withstand the high pressures and temperatures within the engine environment. The tube’s design ensures efficient oil flow and minimizes the risk of leaks or blockages, contributing to the overall reliability of the lubrication system 2.

Benefits of Proper Lubrication

Effective lubrication offers several advantages for heavy-duty truck engines. It reduces friction between moving parts, which in turn decreases wear and tear. Proper lubrication also helps in dissipating heat, which is generated during engine operation. These factors contribute to enhanced engine performance and longevity, making the Lubricating Oil Supply Tube a key component in maintaining engine health 4.

Installation and Compatibility

For the Lubricating Oil Supply Tube to function correctly, it must be installed according to manufacturer guidelines. Compatibility with specific Cummins engine models and other relevant components is crucial to ensure optimal performance. Proper installation and compatibility help in maintaining the integrity of the lubrication system and the overall efficiency of the engine 1.

Maintenance and Troubleshooting

Regular maintenance of the Lubricating Oil Supply Tube is recommended to ensure it continues to function correctly. This includes checking for signs of wear, leaks, or blockages. Common issues that may arise include oil leaks or reduced oil flow, which can often be addressed through routine inspections and timely replacements or repairs 3.

Safety Considerations

When working with the Lubricating Oil Supply Tube and the lubrication system, it is important to follow safety practices. This includes ensuring the engine is cool before beginning any maintenance or repair work, using appropriate personal protective equipment, and following all manufacturer guidelines to avoid injuries or damage to the engine components 1.

Cummins Corporation Overview

Cummins is a renowned manufacturer in the heavy-duty truck industry, known for its wide range of engine components and systems. The company has a history of innovation and commitment to quality, which is reflected in its products, including the Lubricating Oil Supply Tube 3430121. Cummins’ reputation for reliability and performance makes it a preferred choice for heavy-duty truck engines 1.

Compatibility of Lubricating Oil Supply Tube 3430121

The Cummins part number 3430121, identified as a Lubricating Oil Supply Tube, is designed to facilitate the efficient flow of lubricating oil, which is essential for maintaining engine health and performance. This part is compatible with several engine models, including QSW/QSV82, QSW27, QSW36, and QSW73 engines, ensuring a reliable connection between the oil supply system and the engine components that require lubrication 1.

Role of Lubricating Oil Supply Tube 3430121 in Engine Systems

The Lubricating Oil Supply Tube 3430121 is an essential component in the lubrication system of an engine, ensuring that vital moving parts receive a consistent supply of lubricating oil. This tube is integral to maintaining the efficiency and longevity of the engine by facilitating the smooth operation of various components 4.

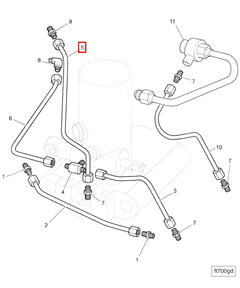

Integration with Fuel Assembly Plumbing

In engines where the fuel assembly plumbing is complex, the Lubricating Oil Supply Tube works in conjunction with the fuel lines to ensure that the fuel system components, such as injectors and pumps, are adequately lubricated. This lubrication reduces friction and wear, enhancing the precision and reliability of fuel delivery 3.

Coordination with General Plumbing

The Lubricating Oil Supply Tube is also a key player in the general plumbing of the engine. It connects to the oil pump, which draws oil from the sump and distributes it throughout the engine. The tube ensures a steady flow of oil to critical areas such as the crankshaft, camshaft, and valve train. This consistent oil supply is vital for reducing metal-to-metal contact, which can lead to excessive wear and potential engine failure 2.

Supporting Fuel System Components

Within the fuel system, the Lubricating Oil Supply Tube supports components like the fuel injectors and fuel rails. By providing a reliable oil supply, it helps maintain the tight tolerances required for efficient fuel atomization and combustion. This, in turn, contributes to better engine performance and fuel economy 3.

Enhancing Overall Engine Performance

The seamless integration of the Lubricating Oil Supply Tube with the engine’s fuel and general plumbing systems underscores its importance in maintaining overall engine health. Proper lubrication ensures that all moving parts operate within their designed parameters, leading to reduced maintenance needs and extended engine life 4.

Conclusion

The Lubricating Oil Supply Tube 3430121 by Cummins plays a vital role in the lubrication system of heavy-duty truck engines. Its proper function ensures efficient operation, reduced wear and tear, and extended engine life. Regular maintenance and adherence to safety practices are essential for the optimal performance of this critical component.

-

Cummins Inc. Operation and Maintenance Manual for ISF2.8 CM2220 F122 Engines. Bulletin Number 5467377.

↩ ↩ ↩ ↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ ↩ -

Wharton, A. J. Diesel Engines. Butterworth-Heinemann Ltd, 1991.

↩ ↩ ↩ ↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.