This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3521439 Oil Slinger is a component designed to enhance the lubrication system in heavy-duty trucks. Its purpose is to ensure that engine components receive adequate lubrication, which is vital for the efficient operation and longevity of the engine. By facilitating the distribution of oil to critical parts, this Cummins part plays a significant role in maintaining the overall performance and reliability of heavy-duty truck engines.

Basic Concepts of an Oil Slinger

An oil slinger is a device used within an engine to aid in the distribution of lubricant. It operates by utilizing the rotational motion of the engine to fling oil onto various components, ensuring they remain adequately lubricated. This mechanism is important for maintaining the lubrication of parts that may not receive sufficient oil flow through conventional means. By enhancing the lubrication process, an oil slinger helps reduce friction and wear on engine components, contributing to smoother operation and extended engine life 1.

Purpose of the Cummins 3521439 Oil Slinger

The Cummins 3521439 Oil Slinger is specifically designed to distribute oil within the engine’s lubrication system. It plays a role in ensuring that critical components, such as bearings and other moving parts, receive a consistent supply of lubricant. This consistent lubrication helps maintain optimal performance and reduces the risk of wear and damage to engine parts. By enhancing the lubrication process, this Cummins part contributes to the overall efficiency and reliability of the engine 2.

Key Features

The Cummins 3521439 Oil Slinger is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high temperatures and pressures present within a heavy-duty truck engine. The design of the oil slinger allows it to effectively distribute oil to critical components, ensuring they remain well-lubricated. Additionally, the materials used in its construction are selected for their durability and resistance to wear, enhancing the performance and longevity of the component 3.

Benefits of Using the Cummins 3521439 Oil Slinger

Incorporating the Cummins 3521439 Oil Slinger into an engine’s lubrication system offers several advantages. It contributes to improved engine longevity by ensuring that critical components are consistently lubricated, reducing wear and tear. Enhanced performance is another benefit, as proper lubrication allows engine parts to operate more smoothly and efficiently. Reliable lubrication provided by the oil slinger also helps prevent unexpected engine failures, contributing to the overall reliability of the vehicle 4.

Installation Process

Installing the Cummins 3521439 Oil Slinger requires careful attention to detail to ensure proper function. The process begins with preparing the engine by ensuring it is clean and free of any debris that could interfere with the installation. The oil slinger should be positioned according to the manufacturer’s specifications, ensuring it is securely attached and aligned correctly. Tools required for installation may include wrenches and screwdrivers, depending on the specific design of the oil slinger. Following the manufacturer’s guidelines for installation will help ensure the component functions as intended.

Common Issues and Troubleshooting

Common issues associated with oil slingers can include inadequate lubrication of engine components, which may be due to improper installation or wear on the slinger itself. Troubleshooting these issues involves inspecting the oil slinger for signs of damage or misalignment and ensuring it is correctly installed. Regular maintenance and inspection can help identify potential problems early, allowing for timely corrections and preventing more serious engine issues.

Maintenance Tips

To ensure the Cummins 3521439 Oil Slinger operates at optimal performance, regular maintenance is recommended. This includes inspecting the component for signs of wear or damage during routine engine maintenance checks. Cleaning the oil slinger to remove any buildup of dirt or debris is also important, as this can affect its ability to distribute oil effectively. Following these maintenance tips will help ensure the longevity and reliability of the oil slinger, contributing to the overall performance of the engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the automotive industry, particularly in the production of heavy-duty truck components. The company’s commitment to innovation and excellence has made it a trusted name among professionals in the field, ensuring that its products, including the Cummins 3521439 Oil Slinger, meet the high standards required for heavy-duty applications.

Cummins Oil Slinger Part 3521439 Compatibility

The Cummins Oil Slinger part number 3521439 is a critical component designed to manage and circulate oil within the engine, ensuring optimal lubrication and performance. This part is compatible with several Cummins engine models, including:

- K19

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

These engines are known for their robust design and are often used in heavy-duty applications. The Oil Slinger part 3521439 fits seamlessly into these engines, providing efficient oil distribution and helping to maintain engine health.

Additionally, the Oil Slinger part 3521439 is also compatible with the:

- NH/NT 855

- QSK38 CM850 MCRS

These engines, while differing in specifications and applications, also benefit from the precise oil management provided by the part 3521439. The compatibility ensures that the oil slinger can effectively handle the unique demands of each engine type, contributing to overall engine longevity and reliability.

Role of Part 3521439 Oil Slinger in Engine Systems

The Part 3521439 Oil Slinger is an essential component that ensures the efficient operation of various engine systems by managing oil distribution and minimizing oil accumulation. Here’s how it integrates with the provided components:

Assembly Core and Core Assembly H3B

In the Assembly Core and Core Assembly H3B, the oil slinger plays a significant role in preventing oil pooling within the core. By flinging excess oil away from critical areas, it helps maintain optimal lubrication and reduces the risk of oil-related failures.

Cam Follower Housing and Camshaft

Within the Cam Follower Housing and in conjunction with the Camshaft, the oil slinger ensures that the camshaft bearings receive a consistent supply of oil. This consistent lubrication is vital for the smooth operation and longevity of the camshaft.

Cylinder Head

In the Cylinder Head, the oil slinger assists in managing oil flow to various passages and bearings. This ensures that all moving parts within the cylinder head are adequately lubricated, contributing to efficient engine performance and reduced wear.

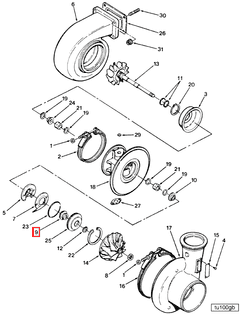

EBM-Performance Parts and EBM-Turbocharger

For EBM-Performance Parts and EBM-Turbocharger applications, the oil slinger is instrumental in maintaining the turbocharger’s lubrication system. It helps in dispersing oil effectively within the turbocharger housing, ensuring that the turbine and compressor wheels are well-lubricated.

Heat3B Bearing/Seal Kit and Heat3B Turbocharger

In the Heat3B Bearing/Seal Kit and Heat3B Turbocharger, the oil slinger enhances the lubrication process by ensuring that oil is evenly distributed across the bearing surfaces. This is particularly important for high-performance turbochargers where precise lubrication is necessary to handle increased thermal and mechanical loads.

Heat60 Turbocharger and Heat60 Turbocharger Repair Kit

For the Heat60 Turbocharger and during repairs with the Heat60 Turbocharger Repair Kit, the oil slinger ensures that oil is effectively managed within the turbocharger. This is essential for maintaining the integrity of the turbocharger’s internal components under high-stress conditions.

Injector and Supercore Assembly 4LGK

In systems involving the Injector and Supercore Assembly 4LGK, the oil slinger helps in maintaining a clean oil supply. By preventing oil sludge and buildup, it ensures that the injectors and other precision components operate within specified parameters.

Turbocharger Kit and Turbocharger Parts Kit

Within the Turbocharger Kit and Turbocharger Parts Kit, the oil slinger is a key component in the lubrication subsystem. It ensures that all turbocharger parts, from the turbine to the compressor, receive the necessary lubrication for optimal performance and durability.

HC3 and Turbo

In the HC3 system and general Turbo applications, the oil slinger contributes to the overall efficiency of the lubrication system. It helps in maintaining a balanced oil film on rotating parts, which is essential for the turbocharger’s reliable operation.

By effectively managing oil distribution and preventing accumulation, the Part 3521439 Oil Slinger enhances the performance and reliability of these engine components.

Conclusion

The Cummins 3521439 Oil Slinger is a vital component in the lubrication system of heavy-duty truck engines. Its role in ensuring consistent oil distribution to critical engine parts contributes to the overall efficiency, performance, and reliability of the engine. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engine models are essential for maximizing the benefits of this part. By integrating effectively with different engine systems, the oil slinger plays a crucial part in maintaining engine health and longevity.

-

Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems, Owen C Duffy and Gus Wright, Jones Bartlett Learning, 2016

↩ -

Reducing Particulate Emissions in Gasoline Engines, Thorsten Boger, Willard Cutler, SAE International, 2018

↩ -

SAE International’s Dictionary of Testing, Verification and Validation, Jon M. Quigley, SAE International, 2023

↩ -

Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.