This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3523980 Oil Slinger is a component designed to enhance the lubrication system in heavy-duty truck engines. Its purpose is to ensure that oil is effectively distributed throughout the engine, contributing to the overall efficiency and longevity of the engine. This part is significant in maintaining optimal engine performance and reducing wear on critical components.

Basic Concepts of an Oil Slinger

An oil slinger is a device used within an engine to help distribute oil more evenly. It operates by spinning with the crankshaft or other rotating components, flinging oil outward to coat various parts of the engine. This mechanism plays a role in the lubrication system by ensuring that all moving parts receive adequate lubrication, which is vital for reducing friction and wear 1.

Purpose of the Cummins 3523980 Oil Slinger

The Cummins 3523980 Oil Slinger is specifically designed to enhance the lubrication system in truck engines. It functions by attaching to the crankshaft and rotating at high speeds, which helps to fling oil onto the cylinder walls and other components. This ensures that these parts remain well-lubricated, which contributes to smoother operation and reduced wear.

Key Features

The Cummins 3523980 Oil Slinger is characterized by several design elements that enhance its performance. It is typically made from durable materials that can withstand the high temperatures and pressures within an engine. The design includes vanes or fins that are optimized to fling oil effectively. Additionally, it is engineered to fit precisely within the engine, ensuring compatibility and efficient operation.

Benefits of Using the Cummins 3523980 Oil Slinger

Incorporating the Cummins 3523980 Oil Slinger into a truck engine’s lubrication system offers several advantages. It helps to improve engine lubrication by ensuring that oil is distributed more evenly. This can lead to reduced wear on engine components, enhanced overall engine performance, and potentially extended engine life. Additionally, proper lubrication contributes to more efficient engine operation, which can result in better fuel economy 2.

Installation and Integration

Installing the Cummins 3523980 Oil Slinger involves several steps to ensure it is properly integrated into the engine. First, the engine must be prepared, which may include cleaning the area where the slinger will be installed. The slinger is then attached to the crankshaft, ensuring it is securely fastened. It is important to follow manufacturer guidelines to avoid any issues during installation. Once installed, the engine should be tested to confirm that the slinger is functioning correctly.

Troubleshooting Common Issues

Common problems associated with oil slingers can include inadequate oil distribution, which may lead to increased engine wear. Potential causes can range from improper installation to wear on the slinger itself. Troubleshooting steps may involve inspecting the slinger for damage, ensuring it is correctly installed, and checking the overall lubrication system for any issues. Regular maintenance can help prevent many of these problems 3.

Maintenance Practices

Maintaining the Cummins 3523980 Oil Slinger is important for ensuring its continued effective operation. This includes regular inspection intervals to check for any signs of wear or damage. Cleaning the slinger as part of routine engine maintenance can also help ensure it functions optimally. If significant wear is detected, considering replacement may be necessary to maintain the efficiency of the lubrication system.

Cummins Overview

Cummins Inc. is a well-established company with a long history in the automotive and heavy-duty truck industry. Known for its wide range of products, including engines, filtration, and power generation equipment, Cummins has built a reputation for quality and reliability. The company’s commitment to innovation and customer satisfaction has made it a trusted name in the industry.

Cummins Oil Slinger Part 3523980 Compatibility

The Cummins Oil Slinger part number 3523980 is a critical component designed to ensure proper lubrication within various Cummins engine models. This part is engineered to fit seamlessly into a range of Cummins engines, enhancing their operational efficiency and longevity. Below is a detailed overview of the engines with which this oil slinger is compatible.

Compatible Engines

-

QSK19 Series

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM500

- QSK19 CM850 MCRS

-

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

-

QSK45 Series

- QSK45 CM500

-

QSK50 Series

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

-

QSK60 Series

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

-

QSK78 Series

- QSK78 CM500

-

QSK95 Series

- QSK95 CM2350 K111

-

QST30 Series

- QST30 CM552

-

QSV Series

- QSV81G

- QSV91G

- QSW/QSV82

-

Other Cummins Engines

- 6B5.9

- K19

- K38

- K50

- N14 MECHANICAL

- NH/NT 855

Grouping of Compatible Engines

The Cummins Oil Slinger part 3523980 is designed to fit a diverse array of engine models, spanning various series and configurations. The compatibility extends across multiple series, including the QSK19, QSK38, QSK45, QSK50, QSK60, QSK78, QSK95, QST30, and QSV series. Additionally, it is compatible with other notable Cummins engines such as the 6B5.9, K19, K38, K50, N14 MECHANICAL, and NH/NT 855.

This extensive compatibility ensures that the oil slinger can be effectively utilized across a broad spectrum of Cummins engine applications, providing essential lubrication and contributing to the overall performance and reliability of the engines.

Role of Part 3523980 Oil Slinger in Engine Systems

The Part 3523980 Oil Slinger is an essential component in maintaining the lubrication integrity within various engine systems. Its primary function is to manage and distribute oil effectively, ensuring that all moving parts receive adequate lubrication to operate smoothly and efficiently. Here’s how it integrates with the provided components:

Aftercooler and Aftercooler Plumbing

In the aftercooler system, the oil slinger ensures that oil is evenly distributed across the cooling surfaces. This is vital for maintaining the temperature of the compressed air, which in turn enhances the efficiency of the turbocharger and reduces the risk of thermal stress on components.

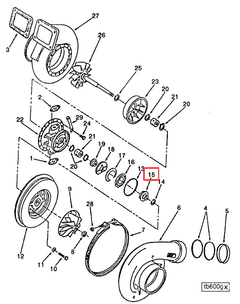

Assembly Turbocharger and EBM: Turbocharger

Within the turbocharger assembly, the oil slinger plays a significant role in lubricating the turbine and compressor wheels. Proper lubrication is essential for minimizing friction and wear, thereby prolonging the lifespan of the turbocharger.

Camshaft and Gear

For the camshaft and gear system, the oil slinger ensures a consistent oil film is maintained on the cam lobes and gear teeth. This reduces wear and tear, ensuring smooth operation and precise valve timing.

Core Assembly and Heat Exchanger

In the core assembly, particularly within the heat exchanger units (such as the Heat Exchanger 85 and Heat Exchanger 80), the oil slinger helps in evenly distributing oil to cool and lubricate the internal components. This is crucial for maintaining the efficiency and reliability of the heat exchanger.

Cylinder Head

The oil slinger contributes to the lubrication of the cylinder head, ensuring that valvetrain components, including lifters and rocker arms, receive adequate oil. This is important for preventing valvetrain noise and ensuring consistent valve operation.

Engine Piston Kit and Short Block

In the engine piston kit and short block assemblies (6C and 6CART), the oil slinger ensures that piston skirts and cylinder walls are well-lubricated. This reduces friction and wear, contributing to the overall durability and performance of the engine.

Injectors and Turbocharger Kit

For fuel injectors and within the turbocharger kit, the oil slinger ensures that moving parts are properly lubricated. This is essential for the precise operation of injectors and the efficient functioning of the turbocharger components.

Oil Connection and Oil Manifold

The oil slinger works in conjunction with the oil connection and oil manifold to ensure that oil is effectively circulated throughout the engine. This setup is fundamental for maintaining optimal lubrication across all critical engine components.

Overhaul Kit and Performance Parts

In an overhaul kit and various performance parts, the oil slinger ensures that newly installed or upgraded components receive consistent lubrication. This is key for maximizing the performance and longevity of these parts.

Rotor Heat Exchanger Assembly and Turbocharger Heat Exchanger

Finally, in the rotor heat exchanger assembly and turbocharger heat exchanger, the oil slinger ensures that all rotating and stationary parts are well-lubricated. This is essential for the efficient transfer of heat and the smooth operation of these complex systems.

Conclusion

The Cummins 3523980 Oil Slinger plays a crucial role in the lubrication system of heavy-duty truck engines. By ensuring even distribution of oil, it helps reduce wear on engine components, enhances performance, and contributes to the longevity of the engine. Proper installation, regular maintenance, and troubleshooting common issues are essential for maximizing the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.