This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Lubricating Oil Supply Tube, part number 3627020, is a component manufactured by Cummins, a well-established name in the automotive industry. This tube is integral to the lubrication system of heavy-duty truck engines, facilitating the delivery of oil to various engine components. Its role is vital in maintaining the efficiency and longevity of the engine.

Function and Operation

The Lubricating Oil Supply Tube operates within the engine’s lubrication system by channeling oil from the oil pump to critical engine components. It ensures a steady and regulated flow of oil, which is necessary for the lubrication of moving parts such as bearings, pistons, and other mechanical elements. This consistent oil supply helps in reducing friction and wear, thereby contributing to the smooth operation of the engine 1.

Purpose of the Lubricating Oil Supply Tube

The primary purpose of this Cummins part in a truck’s engine is to deliver oil efficiently to where it is needed most. This targeted oil delivery plays a role in enhancing engine performance by ensuring that all moving parts are adequately lubricated. Proper lubrication is key to minimizing wear and tear, which in turn contributes to the engine’s longevity and reliability 2.

Key Features

The Lubricating Oil Supply Tube is characterized by several key features that enhance its functionality. It is typically made from durable materials that can withstand high temperatures and pressures within the engine environment. The design of the tube may include specific fittings and connections that ensure a secure and leak-free attachment to the engine’s oil system. Additionally, the tube’s internal diameter and length are engineered to maintain optimal oil flow rates.

Benefits

The advantages of using the Lubricating Oil Supply Tube include improved engine efficiency due to effective lubrication of moving parts. This results in reduced friction and wear, leading to enhanced overall reliability of the truck’s engine. Proper lubrication also aids in heat dissipation, contributing to the engine’s stable operation under various conditions 3.

Installation and Compatibility

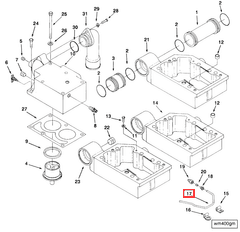

For the proper installation of the Lubricating Oil Supply Tube, it is important to follow manufacturer guidelines. This includes ensuring that the tube is correctly aligned and securely fastened to prevent leaks. Compatibility with various engine models should be verified to ensure optimal performance and integration within the engine’s lubrication system.

Maintenance and Troubleshooting

Routine maintenance of the Lubricating Oil Supply Tube involves regular inspections for signs of wear, leaks, or blockages. It is advisable to check the tube during regular oil changes or engine maintenance sessions. Common troubleshooting tips include verifying the tube’s connections for tightness and inspecting the tube for any physical damage that may impede oil flow.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its high-quality engine components. With a rich history and a strong reputation, Cummins is committed to producing reliable and efficient parts that contribute to the performance and durability of heavy-duty engines. Their products, including the Lubricating Oil Supply Tube, are designed with precision and engineered to meet the demanding requirements of modern truck engines.

Cummins Lubricating Oil Supply Tube (Part 3627020) in Engine Applications

The Cummins Lubricating Oil Supply Tube, identified by part number 3627020, is a critical component in the engine’s lubrication system. This part ensures that oil is efficiently and effectively delivered to various engine parts, maintaining optimal lubrication and reducing wear and tear. The 3627020 oil supply tube is designed to fit seamlessly within the engine architecture, providing a reliable pathway for oil flow.

K19 Engine Series

In the K19 engine series, the 3627020 oil supply tube is meticulously engineered to integrate with the engine’s design. This integration is crucial for maintaining the engine’s performance and longevity. The K19 engines, known for their robustness and efficiency, benefit significantly from the precise fit and function of the 3627020 oil supply tube. The tube’s design ensures that it can withstand the high pressures and temperatures typical of engine operations, providing a stable and uninterrupted oil supply to critical components.

Grouping of Engines

The 3627020 oil supply tube is not limited to a single engine model but is compatible with a range of Cummins engines. This compatibility is due to the standardized design and manufacturing processes employed by Cummins, ensuring that the tube fits snugly and functions optimally across different engine models. The grouping of engines that utilize this part includes those that share similar design principles and lubrication system requirements, ensuring a consistent and reliable performance across the board.

Integration and Functionality

The integration of the 3627020 oil supply tube within the engine is a testament to Cummins’ commitment to quality and precision. The tube is designed to connect seamlessly with the engine’s oil lines and reservoirs, ensuring that oil is distributed evenly and efficiently. This design not only enhances the engine’s performance but also contributes to its durability and reliability. The precise fit and function of the 3627020 oil supply tube are critical for maintaining the engine’s operational integrity and preventing potential issues related to lubrication.

Role of Part 3627020 Lubricating Oil Supply Tube in Engine Systems

The lubricating oil supply tube, part 3627020, is integral to the efficient operation of various engine components. It ensures a consistent flow of oil to areas that require lubrication, thereby enhancing performance and longevity of the engine.

Integration with the Manifold

In engine systems, the manifold plays a significant role in distributing air or fluid to different parts of the engine. The lubricating oil supply tube works in conjunction with the manifold to deliver oil precisely where it is needed. This ensures that moving parts within the manifold receive adequate lubrication, reducing friction and wear.

Interaction with the Water Manifold

The water manifold is responsible for circulating coolant throughout the engine to maintain optimal operating temperatures. The lubricating oil supply tube complements this system by ensuring that oil reaches components that may come into contact with coolant. This prevents overheating and potential damage from insufficient lubrication.

Lubrication of the Rocker Housing

The rocker housing is a critical component in the valve train system, housing the rocker arms that actuate the valves. The lubricating oil supply tube delivers oil to the rocker housing, ensuring smooth operation of the rocker arms. This lubrication is essential for preventing metal-to-metal contact, which can lead to increased wear and potential failure of the valve train components.

Ensuring Smooth Operation of the Water System

The water system within an engine is designed to manage thermal loads by circulating coolant. The lubricating oil supply tube ensures that all components within this system, including pumps and passages, are well-lubricated. This not only enhances the efficiency of the water system but also protects it from undue stress and wear.

Conclusion

In summary, the 3627020 Lubricating Oil Supply Tube is a vital component that supports the functionality and durability of the manifold, water manifold, rocker housing, and the overall water system within an engine. Its role in delivering consistent lubrication to these components cannot be overstated, as it directly contributes to the smooth and reliable operation of the engine.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics (Creative Commons, 2024).

↩ -

Hua Zhao, Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines (CRC Press, 2010).

↩ -

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems (Wiley, 2022).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.