This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

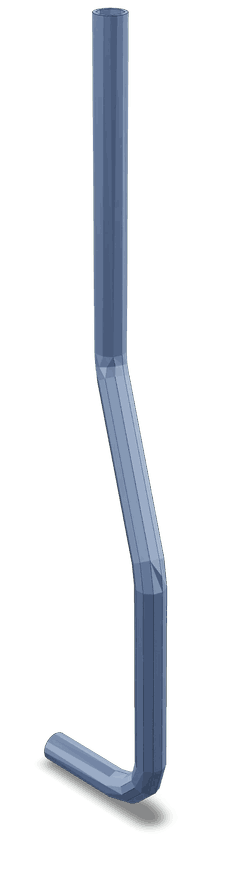

The Lubricating Oil Transfer Tube, identified by Part #3630479, is a component manufactured by Cummins, a leading provider of diesel engines and related technologies. This tube is designed for use in heavy-duty truck engines, where it plays a significant role in the lubrication system. Its purpose is to facilitate the efficient transfer of lubricating oil within the engine, ensuring that all moving parts receive adequate lubrication for optimal performance and longevity 1.

Basic Concepts

The fundamental principle behind the operation of a Lubricating Oil Transfer Tube involves the circulation of oil within the engine’s lubrication system. This tube acts as a conduit, allowing oil to flow from the oil pan to various engine components that require lubrication. By maintaining a consistent flow of oil, it helps reduce friction between moving parts, which is vital for the engine’s efficiency and durability 2.

Purpose and Function

The Lubricating Oil Transfer Tube plays a role in the operation of a truck by enabling the movement of oil within the engine. It ensures that oil is delivered to critical components such as the crankshaft, camshaft, and valve train. This continuous lubrication is necessary to minimize wear and tear, maintain engine performance, and prevent overheating. The tube’s design allows for efficient oil distribution, which is crucial for the engine’s overall health and functionality 3.

Key Features

The primary characteristics of the Lubricating Oil Transfer Tube include its material composition, which is typically made from durable materials to withstand the high temperatures and pressures within the engine. Its design is engineered to ensure a smooth and uninterrupted flow of oil. Additionally, the tube may feature specific attributes such as reinforced sections or unique connectors that enhance its performance and reliability in demanding environments.

Benefits

The advantages provided by the Lubricating Oil Transfer Tube include improved engine performance, longevity, and reliability. By ensuring that oil is efficiently distributed throughout the engine, it helps maintain optimal lubrication, which reduces friction and wear on engine components. This can lead to enhanced engine efficiency, longer service intervals, and overall improved reliability of the heavy-duty truck.

Installation and Compatibility

Proper installation of the Lubricating Oil Transfer Tube is vital to ensure it functions correctly within the engine. It is designed to be compatible with various Cummins engine models, though specific installation procedures may vary. It is important to follow the manufacturer’s guidelines to ensure the tube is securely fitted and properly aligned within the engine’s lubrication system.

Maintenance and Troubleshooting

Regular maintenance of the Lubricating Oil Transfer Tube is necessary to ensure its continued efficient operation. This includes routine inspections for signs of wear, leaks, or damage. Common issues may include blockages or deterioration of the tube, which can impede oil flow. Troubleshooting tips include checking for proper alignment, ensuring connections are secure, and replacing the tube if any damage is detected.

Safety Considerations

When working with the Lubricating Oil Transfer Tube, it is important to observe safety practices and precautions to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning any work, and following all manufacturer guidelines for handling and installation. Additionally, it is crucial to be aware of the high-pressure oil system and take necessary precautions to avoid injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance engines and components. Their product range includes engines, filtration systems, emissions solutions, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Cummins Engine Compatibility with Lubricating Oil Transfer Tube Part 3630479

The Cummins Lubricating Oil Transfer Tube part number 3630479 is designed to fit seamlessly within several engine models, ensuring optimal oil flow and engine performance. This part is integral to the engine’s lubrication system, facilitating the transfer of oil between different components.

K50 Engines

The K50 engine series benefits from the precise engineering of the 3630479 oil transfer tube. This part ensures that oil is efficiently circulated throughout the engine, maintaining the necessary lubrication levels and reducing wear on critical components.

QSK50 CM2150 and QSK50 CM2350 Engines

For the QSK50 CM2150 and QSK50 CM2350 engines, the 3630479 oil transfer tube is a critical component. These engines, known for their robust performance and reliability, rely on this part to maintain the integrity of their lubrication systems. The 3630479 part number ensures that oil is transferred effectively, supporting the engine’s operational demands.

MCRS and K108 Engines

The MCRS and K108 engines also incorporate the 3630479 oil transfer tube. This part is essential for these engines, as it ensures that oil is distributed evenly, preventing overheating and reducing the risk of mechanical failure. The compatibility of this part with these engines highlights its versatility and importance in maintaining engine health.

By integrating the 3630479 oil transfer tube into these engines, Cummins ensures that users can rely on consistent performance and longevity. This part is a testament to Cummins’ commitment to quality and reliability in engine components.

Role of Part 3630479 Lubricating Oil Transfer Tube in Engine Systems

The lubricating oil transfer tube, identified by part number 3630479, is an integral component in the efficient operation of engine systems. This tube facilitates the movement of lubricating oil from one part of the engine to another, ensuring that all moving components receive the necessary lubrication for smooth operation.

Interaction with the Filter

The lubricating oil transfer tube works in conjunction with the oil filter to maintain the cleanliness of the lubricating oil. As oil circulates through the engine, it picks up contaminants and debris. The transfer tube directs the oil to the filter, where these impurities are trapped. Clean oil then continues its journey through the engine, reducing wear and tear on critical components.

Lubricating Oil Distribution

Efficient distribution of lubricating oil is essential for the longevity and performance of an engine. The transfer tube plays a key role in this process by ensuring that oil reaches all necessary points within the engine. This includes bearings, pistons, and other moving parts that require consistent lubrication to function optimally.

Connection to the Filter Head Adapter

The filter head adapter is another component that interfaces with the lubricating oil transfer tube. This adapter serves as a connection point between the transfer tube and the filter, allowing for a secure and leak-free transition of oil. The adapter ensures that the oil flow is uninterrupted and that the filter can effectively perform its role in purifying the oil.

Conclusion

In summary, the Lubricating Oil Transfer Tube (part 3630479) is a vital element in the lubrication system of an engine. It ensures that oil is efficiently transferred to and from the filter, maintaining the cleanliness and quality of the lubricating oil. This, in turn, supports the overall health and performance of the engine by providing consistent lubrication to all moving parts.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.